Ensuring product safety is the top priority for any manufacturer in the food, pharmaceutical, or chemical industries. Contamination can destroy a brand's reputation overnight. Traditional methods like steam or chemical treatment have existed for decades, but they often come with downsides, such as moisture retention or chemical residues. This is where modern technology steps in.

More factories are now choosing to microwave sterilize their products to ensure superior hygiene without compromising quality. This method uses electromagnetic waves to target bacteria and pathogens directly. It is fast, efficient, and dry. For companies looking for reliable machinery to handle this delicate process, brands like Nasan have become key players in providing robust industrial solutions.

What Does It Mean to Microwave Sterilize in Industry?

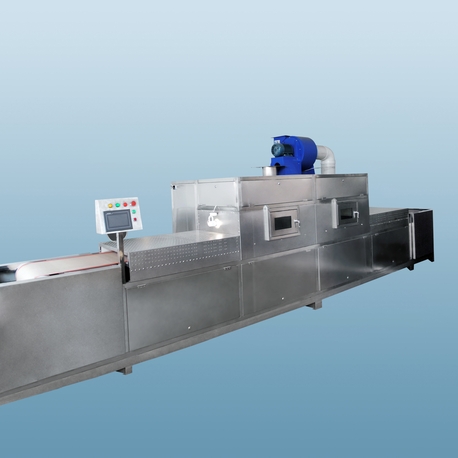

Many people think of microwaves only as kitchen appliances for reheating leftovers. However, in an industrial setting, the technology is vastly different. It involves high-power, continuous tunnel systems designed to process tons of raw materials per hour.

When you microwave sterilize a product, you are utilizing dielectric heating. The microwaves penetrate the material and cause water molecules inside the microorganisms to vibrate at high speeds. This friction generates rapid internal heat.

This process does not just rely on thermal heat. There is also a non-thermal effect. The electromagnetic field itself can disrupt the cell membranes of bacteria, mold, and yeast. This dual action makes it highly effective against stubborn pathogens like Salmonella and E. coli.

Unlike steam, which heats from the outside in, microwaves heat the volume of the product simultaneously. This results in a uniform treatment that destroys pests and bacteria in a fraction of the time required by conventional ovens.

The Core Benefits of Microwave Sterilization

Switching to microwave technology offers distinct advantages for business owners. The most obvious benefit is speed. Conventional heat exchangers or drying rooms can take hours to reach the core temperature needed to kill bacteria. A microwave system can do it in minutes.

Efficiency is another major factor. Because the energy is transferred directly to the product rather than heating the air around it, energy waste is significantly reduced. You don't spend money heating a massive steel chamber; you spend money treating the product itself.

Product quality is better preserved. High temperatures sustained for long periods can degrade vitamins, flavors, and colors in food and herbs. Since the microwave sterilize process is quick, the exposure time to heat is minimal. This keeps spices aromatic and nutritional supplements potent.

Space saving is also a consideration. A microwave tunnel is generally more compact than a massive steam autoclave or a long hot-air drying tunnel. This allows factories to optimize their floor plan for better workflow.

Application Fields: Where is this Technology Used?

The versatility of this technology is impressive. It is not limited to a single sector.

Food Industry: This is the largest user. Spices, powdered ingredients, grains, and nuts often harbor natural bacteria from the field. Microwaves effectively sanitize black pepper, chili powder, and sesame seeds without stripping their essential oils.

Pharmaceuticals: Herbal medicine and raw plant extracts need to be free of contaminants. However, they are also heat-sensitive. The precise control offered by modern equipment allows manufacturers to lower microbial counts to safe levels without ruining the active medicinal compounds.

Chemical Industry: Certain industrial powders and granular materials require drying and sterilization before packaging. Microwaves can remove moisture and contaminants simultaneously, streamlining the production line.

Animal Feed: Pet food and livestock feed must be free from pathogens to prevent sickness in animals. Industrial microwave tunnels process kibble and treats efficiently, ensuring a long shelf life.

How the Process Works: A Step-by-Step Flow

Understanding the workflow helps in planning production lines. Here is how a typical industrial line operates.

First, the raw material is fed onto a conveyor belt. This belt is made of food-grade, microwave-transparent material, usually PTFE or Teflon. The material is spread evenly to ensure uniform exposure.

Next, the material enters the heating chamber. Here, magnetrons (the generators of microwave energy) blast the product with electromagnetic waves. Advanced systems, such as those engineered by Nasan, utilize multiple magnetron sources to ensure there are no "cold spots" where bacteria could survive.

As the product moves through the tunnel, the internal temperature rises rapidly. The moisture inside the bacteria boils, destroying them. Simultaneously, the overall moisture content of the product is reduced, effectively drying and sterilizing in one pass.

Finally, the product moves to a cooling section. It is brought down to a safe handling temperature before being immediately discharged into sterile packaging. This prevents re-contamination.

Solving Common Production Challenges

Manufacturers often face the issue of "uneven heating" when using older drying methods. This leads to some parts of a batch being burnt while others remain damp and contaminated.

To microwave sterilize effectively, modern machines use stirrers and calculated wave reflections to scatter the energy evenly. PLC systems monitor the temperature in real-time. If the temperature drops below the set threshold, the belt slows down automatically to ensure the product gets the required exposure.

Another challenge is energy cost. Gas and steam prices fluctuate. Electricity is generally more stable and controllable. Because microwaves can be turned on and off instantly without a "warm-up" period, the machinery only consumes power when products are actually on the belt.

Companies like Nasan focus on modular designs. This means if production demands increase, a factory can add more modules to the existing line rather than buying an entirely new machine. This scalability is vital for growing businesses.

Replacing Traditional Autoclaves and Steamers

Why are companies moving away from autoclaves? While autoclaves are effective, they are batch processes. You have to load, seal, pressurize, wait, depressurize, and unload. It creates a bottleneck.

Microwave systems are continuous. The conveyor belt never stops. This fits perfectly into modern automation lines where raw materials come in one end and finished goods go out the other.

Furthermore, steam introduces moisture. If you are trying to sterilize a dry powder, adding steam is counter-intuitive because you then have to dry it again. Microwaves can dry and sterilize simultaneously, removing a complete step from the manufacturing process.

Safety and Environmental Considerations

A common misconception is that microwave radiation remains in the food. This is false. Once the power is cut, the waves disappear instantly. There is no residual radiation.

From an operational safety standpoint, industrial machines are heavily shielded. They are equipped with leakage sensors. If a door is opened or a seal is breached, the system shuts down immediately to protect operators.

Environmentally, this technology is greener. It does not produce combustion gases like fossil fuel burners. It creates a cleaner work environment with less ambient heat, which is better for the workers on the floor.

Choosing the Right Equipment Partner

Selecting the right machine is not just about buying a metal box. It is about calibration. The frequency and power density must be matched to the specific product.

A machine calibrated for drying tea leaves might not be suitable for sterilizing vacuum-packed meat. Manufacturers need a vendor who understands the dielectric properties of different materials.

Reliability is paramount. In a 24/7 production environment, downtime costs money. Components like the magnetron and the cooling system for the transformer need to be of high quality. This is why manufacturers often turn to established names like Nasan to ensure they have access to spare parts and technical support when needed.

The demand for cleaner, safer, and higher-quality products is not going away. Regulatory standards regarding bacterial counts in food and medicine are becoming stricter every year. To stay competitive, manufacturers must adopt technologies that deliver consistent results.

When you decide to microwave sterilize your production line, you are investing in efficiency. You eliminate the bottlenecks of batch processing and the energy waste of thermal ovens. You gain control over the precise temperature and moisture levels of your goods.

Whether you are processing spices, pharmaceuticals, or chemical powders, the technology is proven. With the right equipment partner, such as Nasan, transitioning to this modern method can be seamless, securing both the safety of your consumers and the profitability of your business.

FAQ: Frequently Asked Questions

Q1: Will the microwave sterilize process change the taste or color of my food products?

A1: Generally, no. Because the process is much faster than traditional baking or steaming, the product is exposed to heat for a shorter time. This helps preserve the original color, flavor, and nutritional content better than slower thermal methods.

Q2: Is microwave sterilization suitable for packaged goods?

A2: It depends on the packaging material. Microwaves cannot penetrate metal. Therefore, products in foil bags or cans cannot be treated. However, products in microwave-transparent plastics, glass, or paper can be sterilized effectively inside the package.

Q3: How much energy does an industrial microwave machine consume compared to a steam dryer?

A3: While the electrical load may seem high, the overall efficiency is usually better. Microwave energy conversion efficiency is high, often resulting in energy savings of 30% to 50% compared to steam or hot air systems because you are not wasting energy heating the air or the equipment structure.

Q4: Does the equipment require specialized operators?

A4: Most modern industrial systems are controlled by PLC (Programmable Logic Controllers) with touch screens. While the underlying technology is complex, the user interface is designed to be simple. Operators need training on safety and settings, but they do not need to be electrical engineers.

Q5: How often do the magnetrons need to be replaced?

A5: Magnetrons are consumable parts, similar to light bulbs. Their lifespan varies based on usage intensity and cooling efficiency, but generally, high-quality industrial magnetrons last between 5,000 to 8,000 working hours before needing replacement.