Fruit drying is a time-tested preservation method that has evolved significantly with modern technology. In industrial settings, efficiency, consistency, and quality are non-negotiable. An industrial fruit drying machine is engineered to meet these demands by providing precise control over the drying environment. These systems transform perishable fruits into shelf-stable products while preserving their nutritional value, color, and flavor. Manufacturers around the world, including Nasan, design robust machines that cater to the high-volume needs of commercial fruit processors.

How an Industrial Fruit Drying Machine Works

The process of drying fruit industrially involves more than just removing water. It requires managing heat, airflow, and humidity in a controlled manner to achieve optimal results. A commercial fruit drying machine uses a combination of these elements to ensure efficient and uniform drying.

1. Heat Application and Temperature Control

Industrial dryers apply heat through convection, where hot air circulates around the fruit. The temperature must be carefully controlled. Too high, and the fruit can cook or lose nutrients; too low, and drying takes too long, risking spoilage. Most fruits dry effectively between 50°C and 70°C. Modern machines use sensors and programmable controllers to maintain precise temperatures throughout the cycle.

- Convection Heating: Hot air transfers heat to the fruit surface, causing moisture to evaporate.

- Zoned Temperature Control: Different sections of the dryer can maintain different temperatures for optimized drying stages.

- Low-Temperature Options: Some machines offer settings as low as 30°C for delicate fruits to preserve enzymes and vitamins.

2. Airflow and Humidity Management

Uniform airflow is critical. It ensures that every piece of fruit receives the same amount of heat and that moisture is carried away efficiently. Industrial machines use strategically placed fans and duct systems to create consistent airflow patterns. Humidity control is equally important. As moisture evaporates, it increases the humidity inside the chamber. The machine must vent this moist air and replace it with dry air to maintain drying efficiency.

Advanced systems, like those from Nasan, integrate dehumidification or heat pump technology. These features recycle heat and actively remove moisture from the air, significantly improving energy efficiency and drying speed, especially in humid climates.

7 Key Advantages of Using an Industrial Fruit Drying Machine

Investing in a commercial-grade dryer provides distinct benefits that directly impact production capacity, product quality, and operational costs. Here are seven compelling advantages.

1. High Throughput and Scalability

Industrial machines are designed for volume. They can process hundreds or thousands of kilograms of fresh fruit per day. This high throughput supports business growth and allows processors to handle seasonal gluts efficiently. Conveyor-based systems enable continuous operation, maximizing output.

2. Superior Product Quality and Consistency

Precise control over drying parameters ensures consistent results. Every batch has uniform moisture content, color, and texture. This consistency is vital for meeting consumer expectations and securing contracts with retailers. Proper drying also preserves more vitamins and antioxidants compared to traditional sun-drying.

3. Enhanced Energy Efficiency

Modern industrial dryers are built to minimize energy consumption. Features like insulation, heat recovery systems, and efficient fans reduce the cost per kilogram of dried fruit. Heat pump dryers, in particular, can cut energy use by up to 60% compared to conventional hot-air dryers, offering long-term savings.

4. Improved Food Safety and Shelf Life

Controlled industrial drying reduces the water activity of fruit to a level that inhibits the growth of bacteria, yeast, and mold. This extends shelf life to a year or more without chemical preservatives. The enclosed, hygienic design of industrial machines also minimizes contamination risks from dust, insects, or other environmental factors.

5. Operational Flexibility and Versatility

A high-quality fruit drying machine is not limited to one type of fruit. By adjusting settings, you can dry apples, bananas, mangoes, berries, and more. Some machines can also process vegetables, herbs, and even meat, providing excellent return on investment through diversified production.

6. Reduced Labor and Automation

Automated loading, drying, and unloading systems reduce the need for manual labor. Programmable controllers allow operators to set a drying profile and let the machine run with minimal supervision. This lowers labor costs and reduces human error, leading to more reliable production.

7. Durability and Low Maintenance

Built with food-grade stainless steel and industrial components, these machines withstand continuous operation in demanding environments. They are designed for easy cleaning and maintenance, ensuring long service life and minimal downtime. Brands like Nasan focus on reliability to provide a solid return on investment.

Primary Applications in the Food Industry

Dried fruits are versatile ingredients used across multiple sectors. Industrial drying machines enable the production of various products to meet this diverse demand.

The snack industry uses dried fruit as a healthy standalone snack or in trail mixes. Bakeries and confectioneries incorporate them into cakes, cereals, and energy bars. Fruit powders are used in smoothies, baby food, and flavorings for the dairy industry. The pharmaceutical and nutraceutical sectors use dried fruit extracts in supplements. Pet food manufacturers also include dried fruit in premium treat formulations.

Comparing Different Types of Industrial Fruit Dryers

Several dryer designs are available, each with strengths suited to specific production needs. Understanding these options helps in selecting the right machine.

Tray Dryers vs. Conveyor (Belt) Dryers

Tray dryers are batch systems where fruit is placed on trays inside a cabinet. They are flexible for small to medium batches and different products. Conveyor dryers are continuous systems where fruit moves on a belt through drying zones. They offer higher automation and throughput, ideal for large-scale production of a single product type.

Heat Pump Dryers vs. Conventional Hot Air Dryers

Conventional dryers use electric or gas heaters to heat incoming air. They are simpler but less efficient. Heat pump dryers use a refrigeration cycle to dehumidify and recycle heat within the chamber. They operate at lower temperatures with better humidity control, leading to superior product quality and energy savings. This technology is a focus for innovative manufacturers like Nasan.

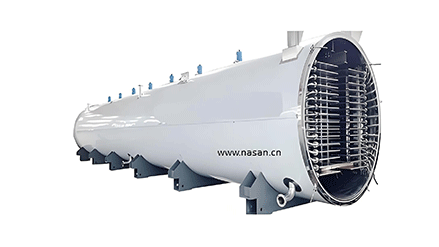

Freeze Dryers vs. Dehydrators

Freeze dryers remove moisture by sublimation under vacuum, preserving the fruit's structure and nutrients exceptionally well. However, they have very high capital and operational costs. Industrial dehydrators (hot air or heat pump) are more cost-effective for most commercial applications, offering a good balance of quality, capacity, and operating expense.

6 Critical Factors for Selecting a Commercial Fruit Dryer

Choosing the right machine requires careful evaluation of your specific production requirements. Consider these six factors to make an informed decision.

- Production Capacity: Determine the volume of fresh fruit you need to process daily and choose a machine that meets or exceeds this capacity.

- Fruit Type and Form: Consider the varieties you will dry and their form (slices, halves, puree). Ensure the machine can handle them effectively.

- Energy Source and Efficiency: Evaluate the availability and cost of electricity, gas, or steam. Compare the specific energy consumption of different dryer models.

- Control System and Automation: Decide on the level of control you need, from manual timers to fully programmable PLCs with data logging.

- Hygiene and Construction: All food-contact surfaces must be stainless steel for easy cleaning and compliance with food safety standards (HACCP, GMP).

- Supplier Reputation and Support: Choose a manufacturer with a proven track record, good technical support, and readily available spare parts, such as Nasan.

Frequently Asked Questions (FAQs)

Q1: What is the average drying time for fruits in an industrial machine?

A1: Drying time varies widely based on fruit type, thickness, moisture content, and machine technology. Thin slices of apple may dry in 4-6 hours, while thicker chunks of mango might take 10-14 hours. Industrial machines are significantly faster than domestic dehydrators due to optimized airflow and higher capacity.

Q2: Can I dry different fruits together in the same batch?

A2: It is not recommended. Different fruits have different drying times and temperature requirements. Drying them together can lead to some being over-dried and others under-dried. It's best to dry similar fruits in separate batches or use a machine with multiple independent drying zones.

Q3: How do I prevent fruits from sticking to the drying trays?

A3: Use trays with non-stick coatings (like PTFE) or silicone mats. For stainless steel trays, lightly spraying them with food-grade oil or using parchment paper can prevent sticking. Some fruits with high sugar content are more prone to sticking and may require pre-treatment.

Q4: What pre-treatment is needed before drying fruits?

A4: Common pre-treatments include washing, peeling, coring, and slicing. To prevent browning (enzymatic oxidation), fruits like apples and bananas can be dipped in ascorbic acid (vitamin C) solution or lightly blanched. These steps help maintain color and improve food safety.

Q5: What is the expected moisture content for commercially dried fruit?

A5: The target moisture content depends on the fruit and desired texture. For shelf-stable, chewy dried fruit (like raisins or apricots), moisture content is typically between 15% and 25%. For crispy fruit chips, it should be below 10%. An industrial fruit drying machine provides the control needed to achieve these targets consistently.

An industrial fruit drying machine is a vital asset for any business involved in fruit processing. It combines advanced engineering with practical design to deliver efficiency, quality, and scalability. By understanding the technology, advantages, and selection criteria outlined here, processors can make confident investment decisions. Partnering with an experienced equipment manufacturer like Nasan ensures access to reliable technology and expert support, paving the way for successful and profitable dried fruit production.