- Vacuum Microwave Dryer

- Microwave Dryer

- Microwave Sterilizer

- Hot Air + Microwave Dryer

-

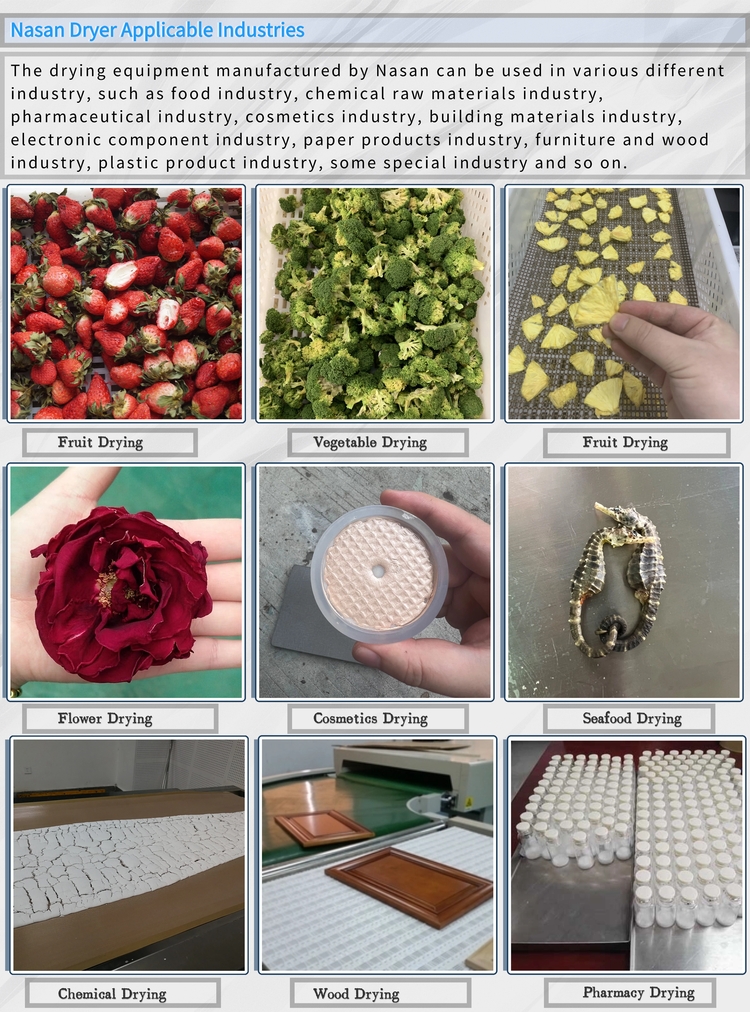

Fruit Dryer

- Nasan Fruit Dryer

- Pineapple Dryer

- Apple Dryer

- Strawberry dryer

- Fruit Vacuum Microwave Dryer

- Small Fruit Dehydrator Drying Machine

- Industrial Fruit Drying Machine

- Industrial Fruit Drying Equipment

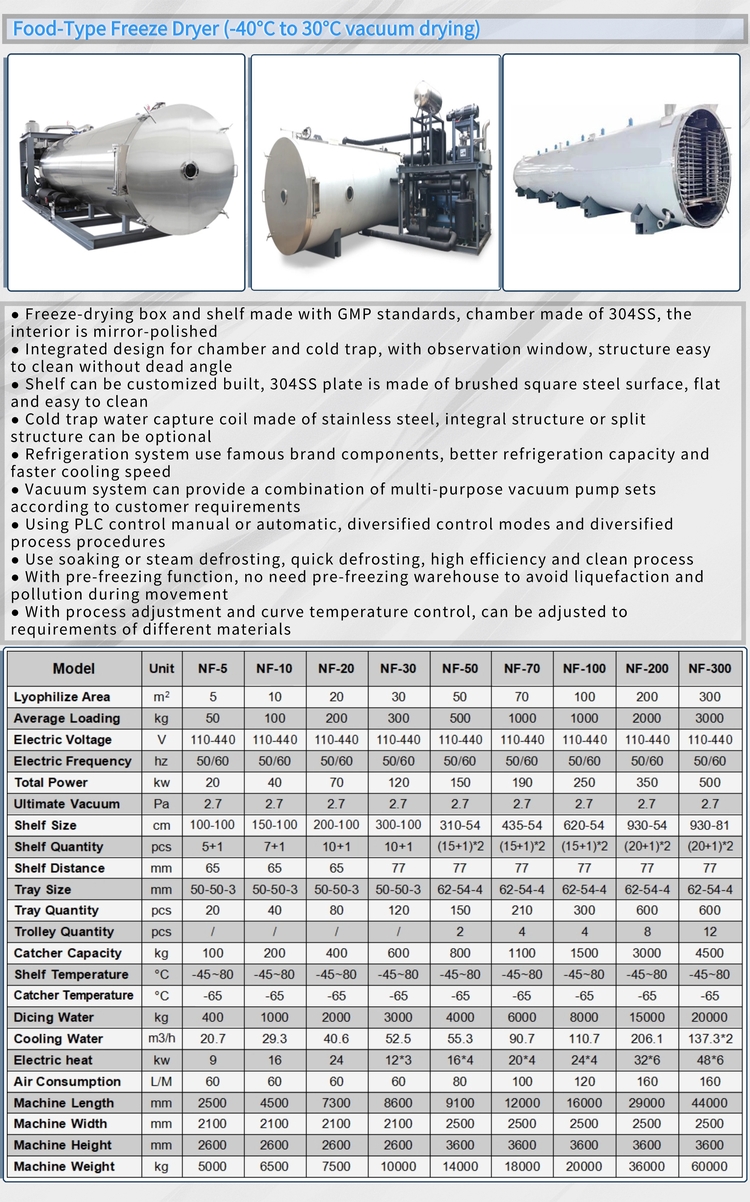

- Fruit Vacuum Freeze Dryer

- Banana Dryer

- Lemon Dryer

- Fruit Dehydrator

- Microwave Fruit Dehydrator Machine

- Figs Dryer

- Monk Fruit Dryer

- Kiwi Dryer

- Mango Dryer

- Red Berry Dryer

- Brown Berry Dryer

- Lycium ruthenicum dryer

-

Food Dryer

- Vacuum Food Drying Machine

- Nasan Food Dehydrator

- Mushroom Dryer

- Fish Dryer

- Spring Onion Dryer

- Leek Dryer

- Ginger Dryer

- Yam Dryer

- Beef Jerky Dryer

- Milk Dryer

- Vegetables Dryer

- Chicken Dryer

- Sea Horse Dryer

- Honey Dryer

- Pet food dryer

- Spices Dryer and Sterilize

- Prawn Shrimp Dryer

- Grain Food Dryer

- Chilli Dryer

- Non-fried instant noodles Dryer

- Flower Dryer

- Chemical Dryer

- Material Dryer

- Pharmacy Dryer

- Vacuum Dryer

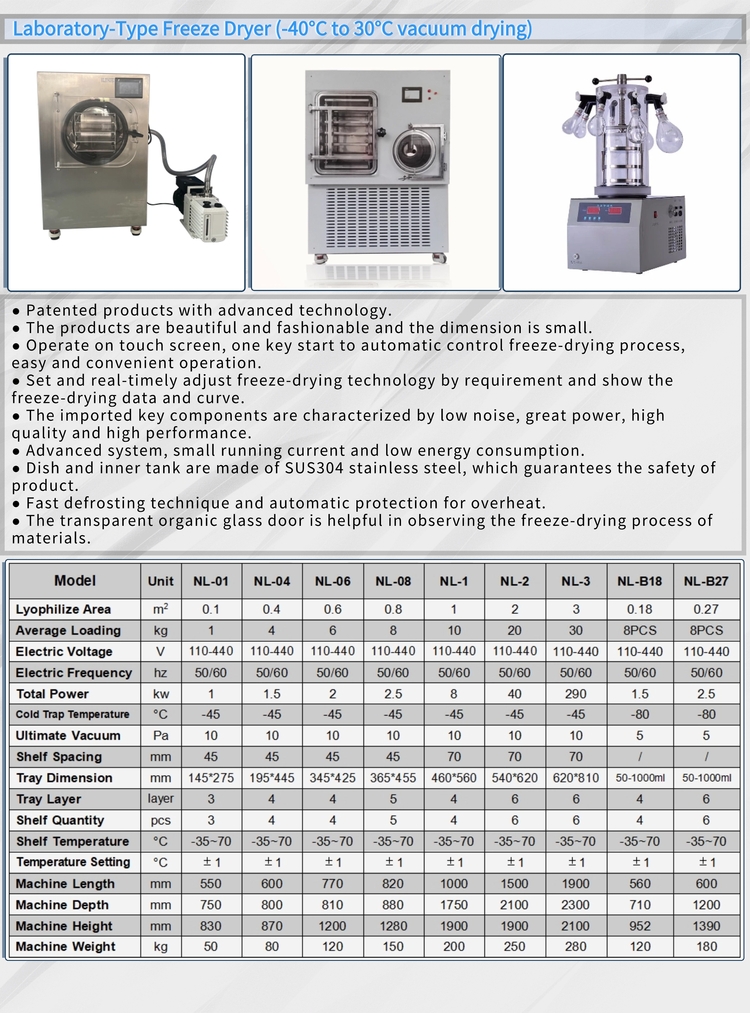

- Lab Scale Dryer

- Other Dryer