A vacuum freeze dryer, also known as a lyophilizer, is a device that dries materials by removing moisture through sublimation under vacuum conditions.

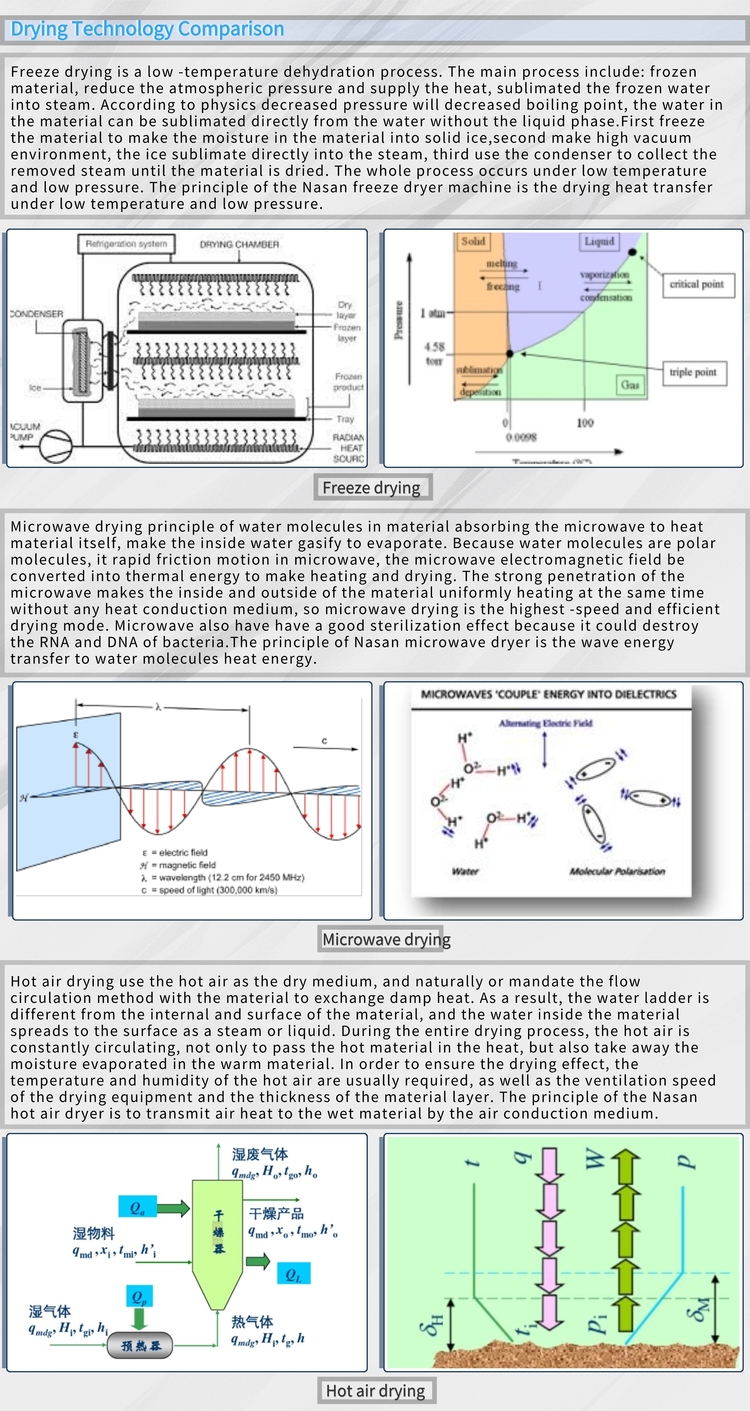

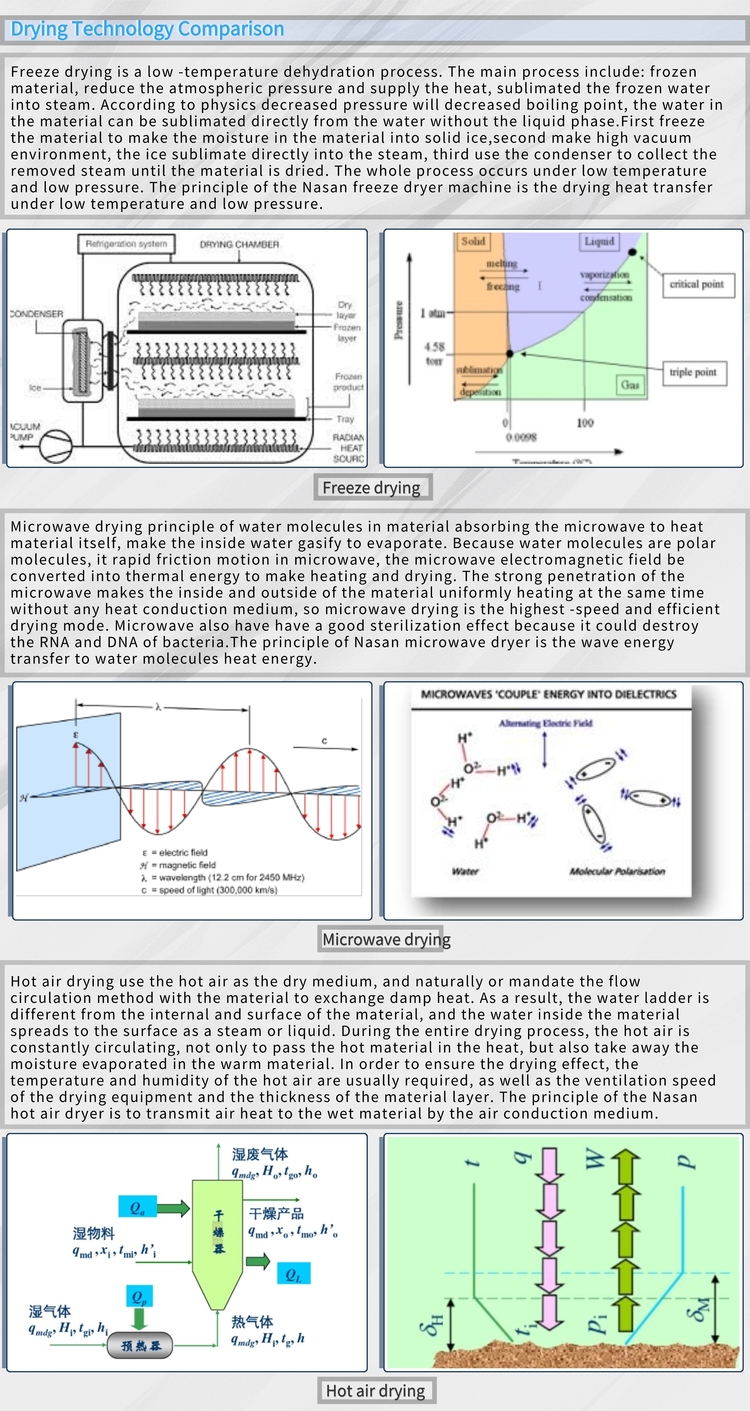

Working Principle

The vacuum freeze dryer first pre-freezes the material to below its eutectic point temperature, causing the water in the material to freeze completely into solid ice. Then, the equipment quickly evacuates to form a high-vacuum environment, reducing the pressure inside the system. In this high-vacuum state, the ice directly sublimes from a solid to a gaseous water vapor without passing through the liquid phase, and is then pumped out of the system by a vacuum pump, ultimately achieving the drying of the material.

Composition

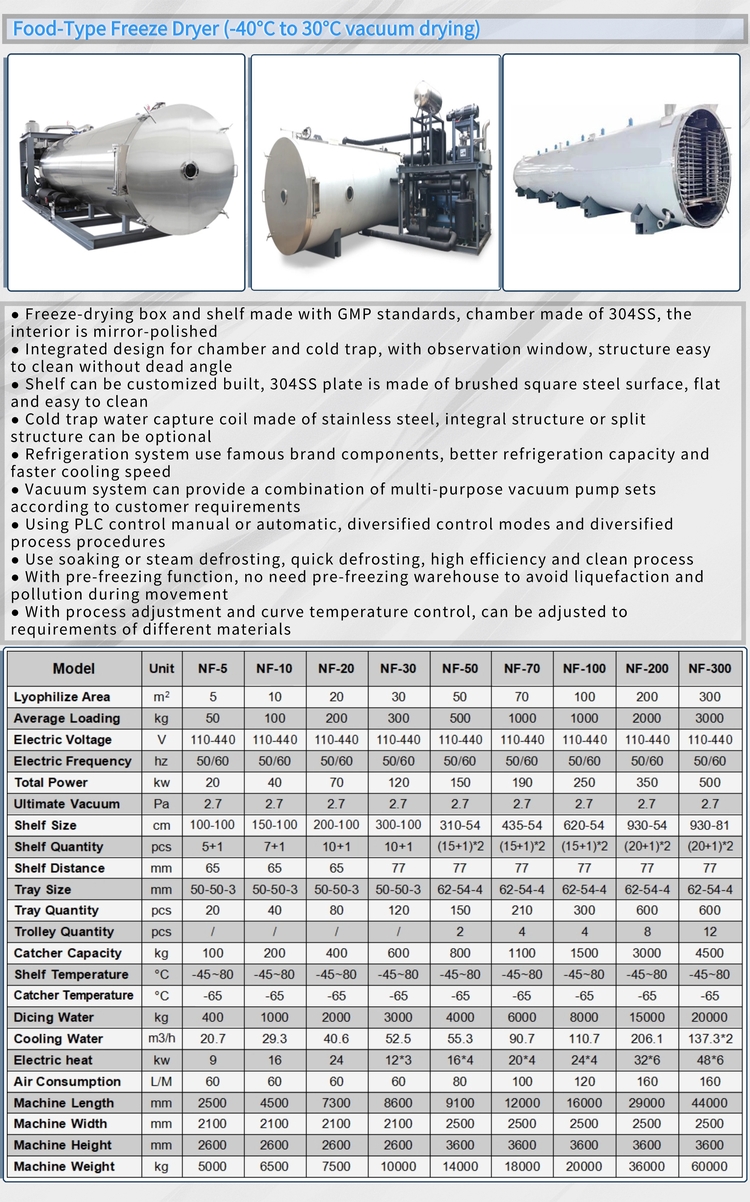

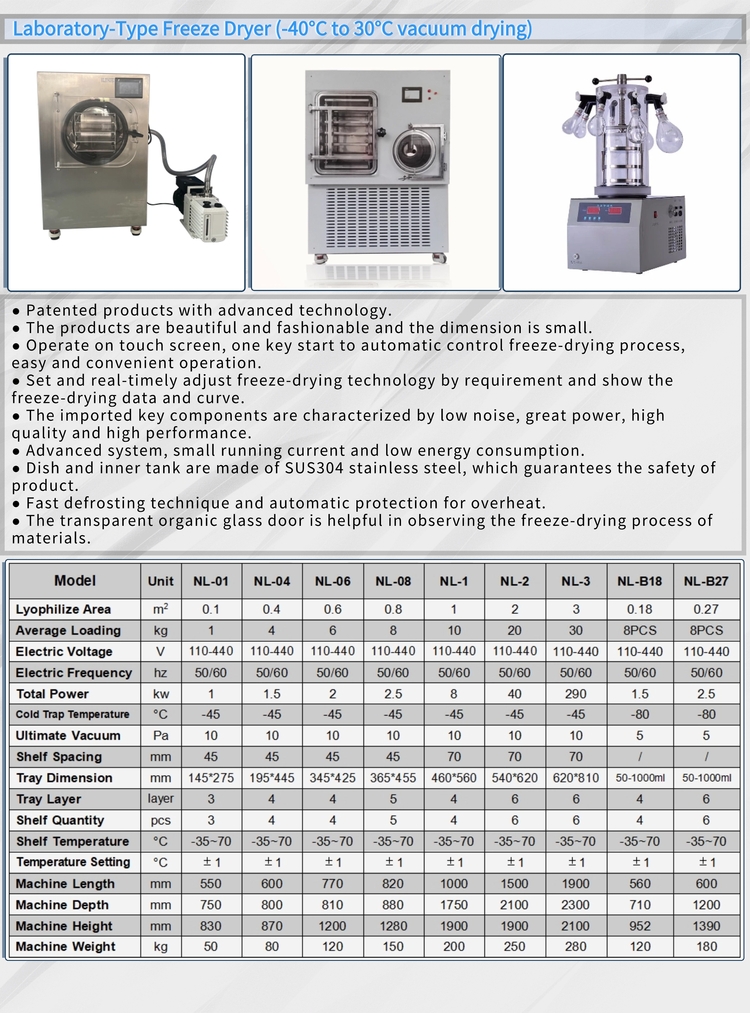

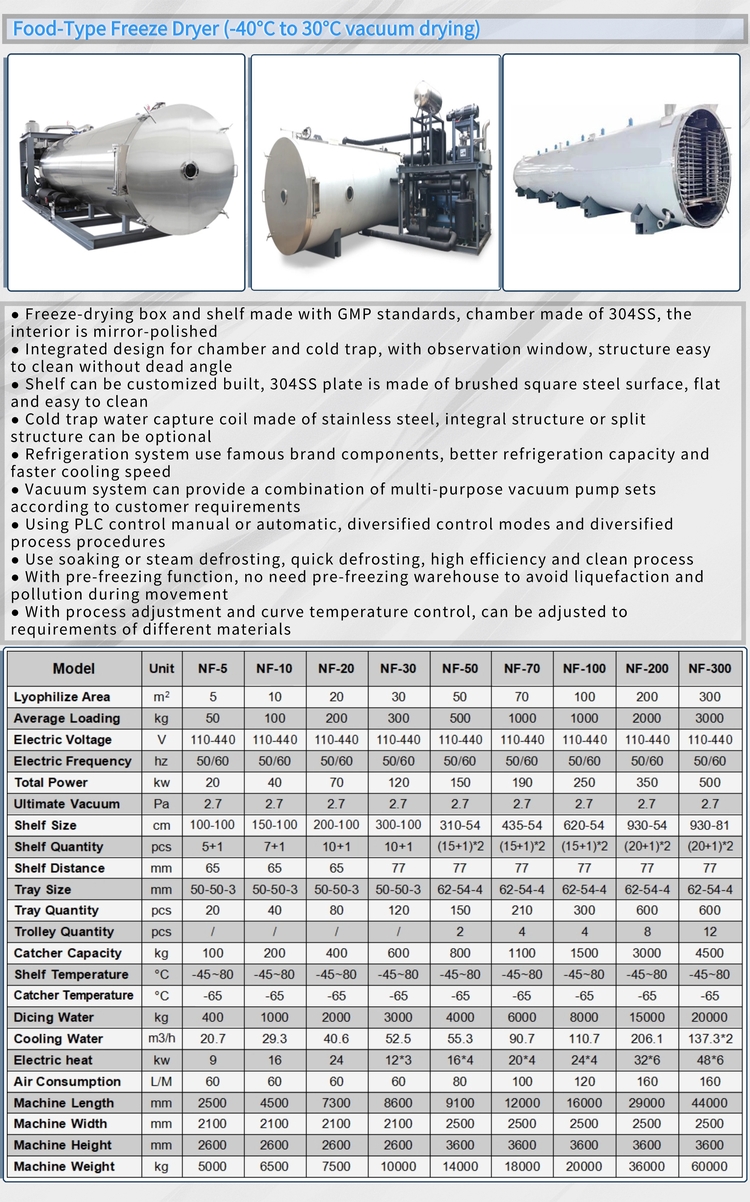

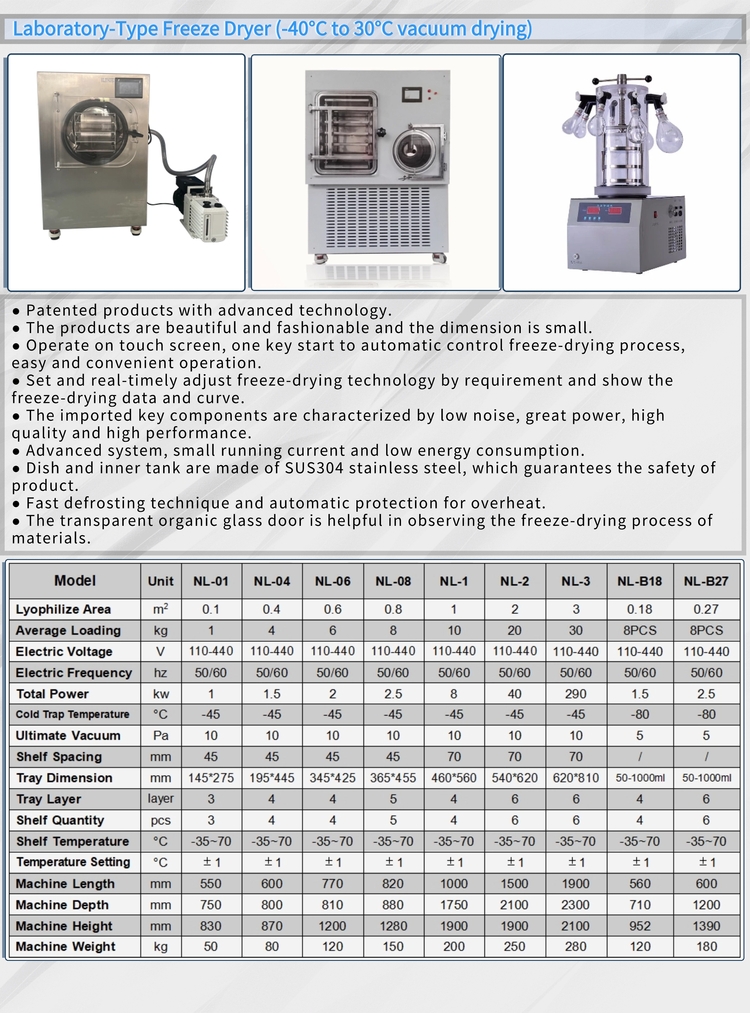

An intermittent freeze dryer is mainly composed of five parts: a drying chamber, a heating system, a vacuum system, a refrigeration system, and a control system. The drying chamber has two main forms, cylindrical and square. The heating system can be divided into contact heating, radiation heating, microwave heating, etc. The vacuum system is responsible for creating a high-vacuum environment, and the refrigeration system is used for pre-freezing materials and condensing water vapor. The control system realizes the automatic operation and parameter adjustment of the equipment.

Performance Characteristics

Good quality preservation: It operates under low-temperature and vacuum conditions, which can effectively avoid the degradation and oxidation of heat-sensitive substances, and completely retain the biological activity, nutritional components, color, and shape of the materials.

Precise control: It has a precise temperature and vacuum control system, which can accurately adjust the pre-freezing temperature, drying temperature, and vacuum degree according to the characteristics of different materials to ensure the drying effect.

High degree of automation: Many vacuum freeze dryers are equipped with intelligent control systems, which can realize automatic operation of the whole process from pre-freezing, sublimation drying to desorption drying, reducing manual intervention and operation errors.

Application Fields

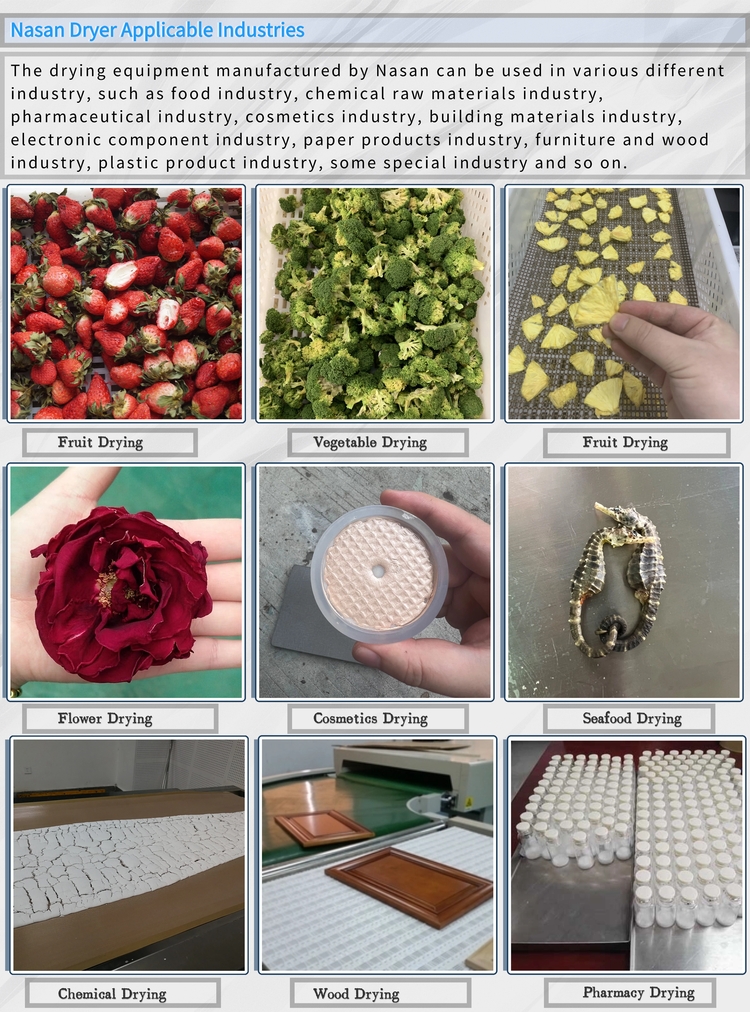

Biomedical field: It is a key equipment for preparing high-quality drugs and biological products, such as antibiotics, vaccines, and blood products. Freeze-drying can effectively extend the shelf life and maintain biological activity.

Food processing field: It is used for processing various foods, such as freeze-dried fruits, vegetables, coffee, etc., which not only retain the color, flavor, and nutrition of fresh ingredients but also have the characteristics of small volume, light weight, and good rehydration performance, which is convenient for storage and transportation.

Aerospace scientific research field: The food required by astronauts in space can meet the nutritional needs and is convenient for storage and consumption after being freeze-dried. At the same time, freeze-drying technology can also be used to preserve biological samples and strains in space experiments.