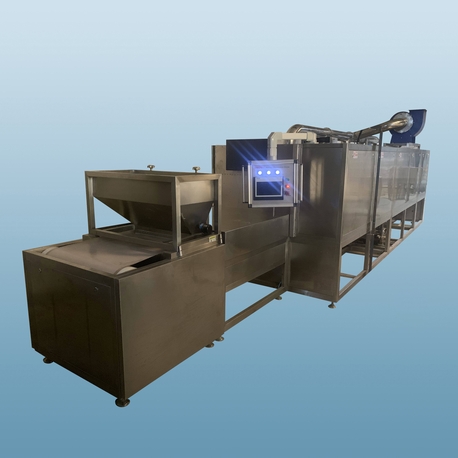

Chemical tunnel microwave drying is a drying technology that uses microwave energy to dry chemical materials. It has the advantages of high efficiency, energy conservation, and good drying quality.

Advantages

High - efficiency Drying: Due to the characteristic of microwave volumetric heating, the heating speed is fast, which can greatly shorten the drying time and improve production efficiency. For example, compared with traditional hot - air drying, the drying time of some chemical materials can be shortened by several times or even dozens of times.

Good Drying Quality: Microwave drying can make the material heat evenly inside and outside, avoiding the problems of "surface hardening" and uneven drying that are prone to occur in traditional drying methods. At the same time, the drying temperature can be accurately controlled to ensure that the chemical properties and physical properties of the material are not damaged, and the quality of the dried product is high.

Energy - saving and Environmental - friendly: Microwave energy is directly absorbed by the material to generate heat, without heat loss through the equipment wall and other parts, and the energy utilization rate is high. Compared with traditional drying methods, it can save a lot of energy. In addition, the drying process does not produce harmful gases and waste, which is in line with the requirements of environmental protection.

Application Scope

Powder Materials: Such as glass fiber, battery materials, cellulose (such as hydroxyethyl cellulose, carboxymethyl cellulose, etc.), mannitol, nickel hydroxide, etc.

Granular Materials: Such as calcium chloride dihydrate, active carbon, zirconium oxychloride, etc.

Pasty Materials: Such as some oil - based ink drying agents, water - based inks, etc.