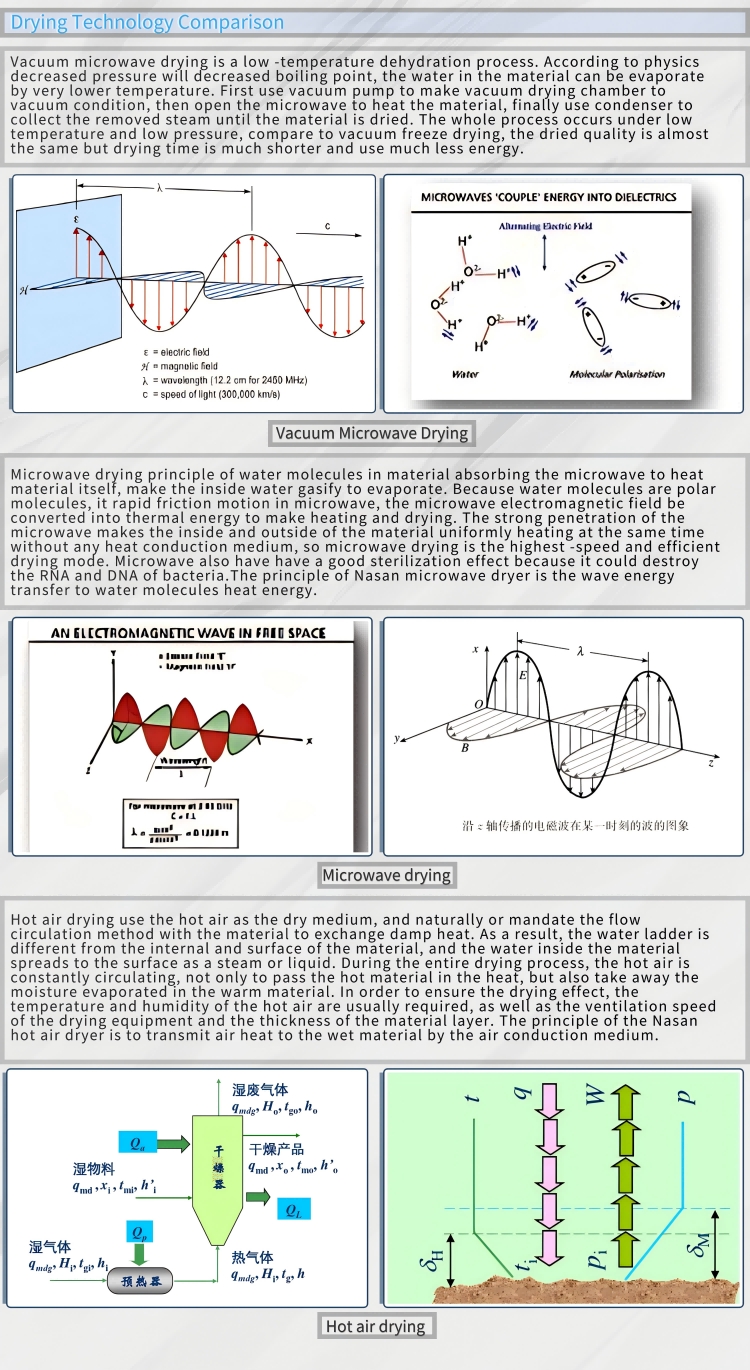

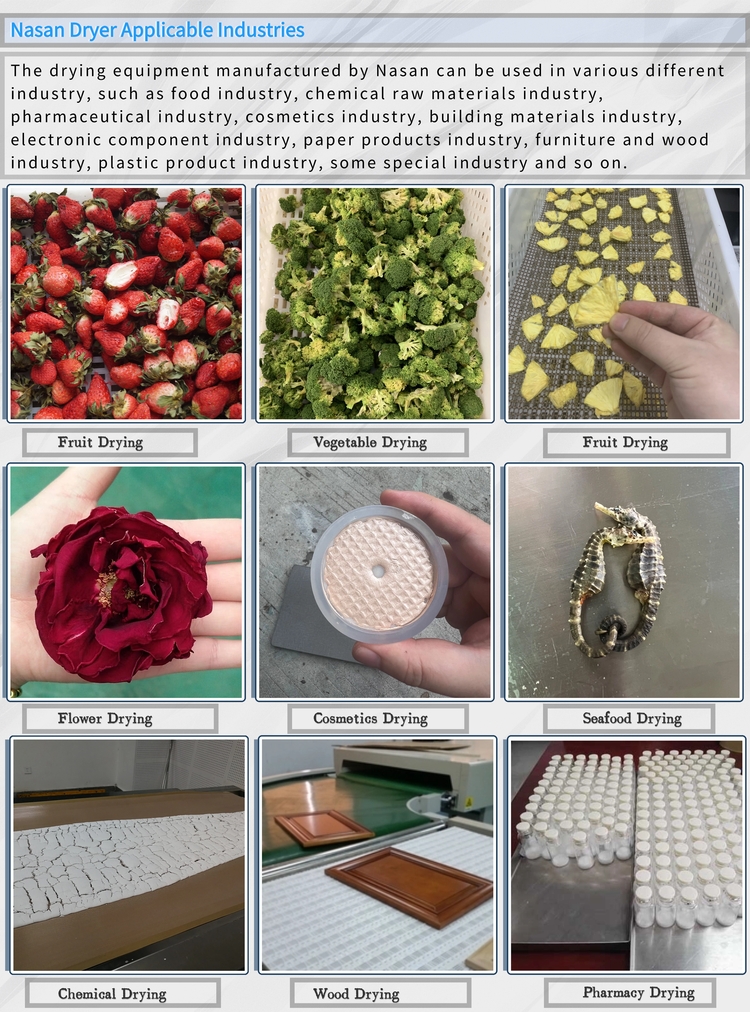

Lycium ruthenicum (commonly known as “black goji berry” or “desert black wolfberry”) is a nutrient-dense superfruit native to arid regions of Central Asia and China. It is prized for its deep purple-black color (from high anthocyanin content), high antioxidant levels, and delicate sweet-tart flavor. However, its thin skin, soft pulp, and heat-sensitive bioactive compounds (anthocyanins, polysaccharides) make traditional drying methods ineffective. Vacuum microwave drying is uniquely suited to process Lycium ruthenicum, as it preserves its vibrant color, nutritional value, and tender texture. Below is a detailed breakdown of this specialized technology.

Why Lycium ruthenicum Requires Vacuum Microwave Drying

Lycium ruthenicum has distinct traits that make conventional drying (hot air, sun drying) impractical or destructive:

High Anthocyanin Sensitivity: Its signature deep purple color comes from cyanidin-3-O-rutinoside (a potent anthocyanin), which degrades rapidly at temperatures above 50°C or when exposed to UV light (common in sun drying).

Delicate Pulp & Thin Skin: Fresh Lycium ruthenicum has soft, juicy pulp and a thin, fragile skin—slow drying (e.g., hot air drying) causes cell collapse, leading to a shrunken, rubbery product and anthocyanin leakage (turns dried berries dull gray).

High Moisture & Mold Risk: Fresh black goji berries contain 80–85% moisture. Slow drying creates a warm, moist environment ideal for mold growth (e.g., Aspergillus), requiring preservatives that compromise its “natural” appeal.

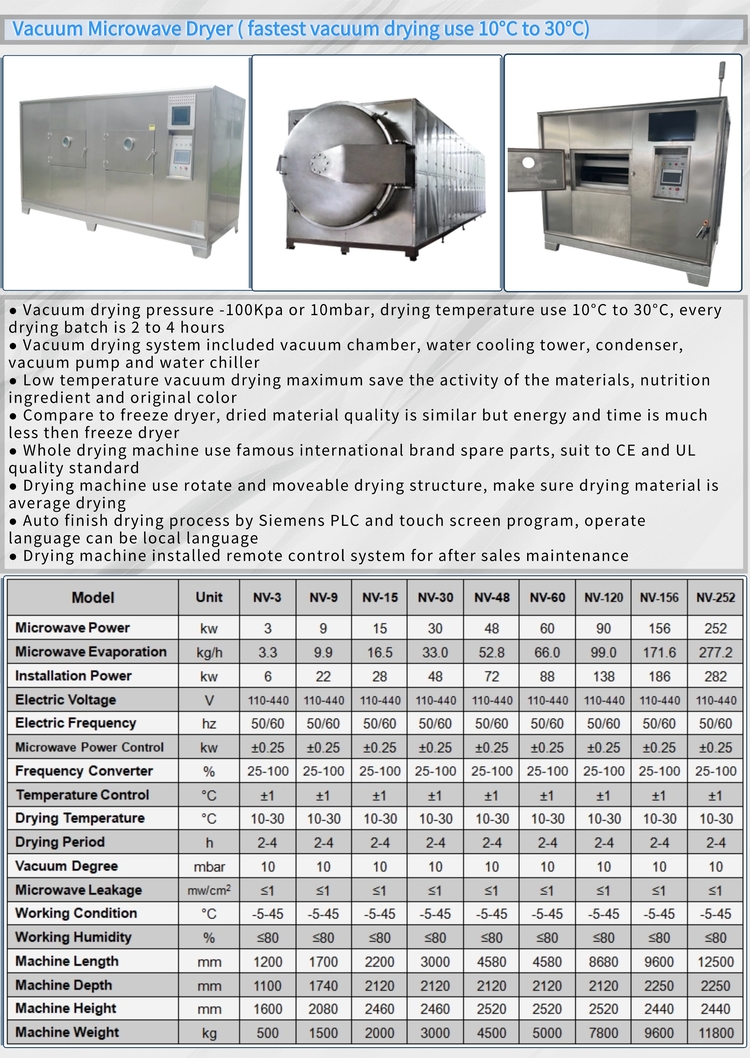

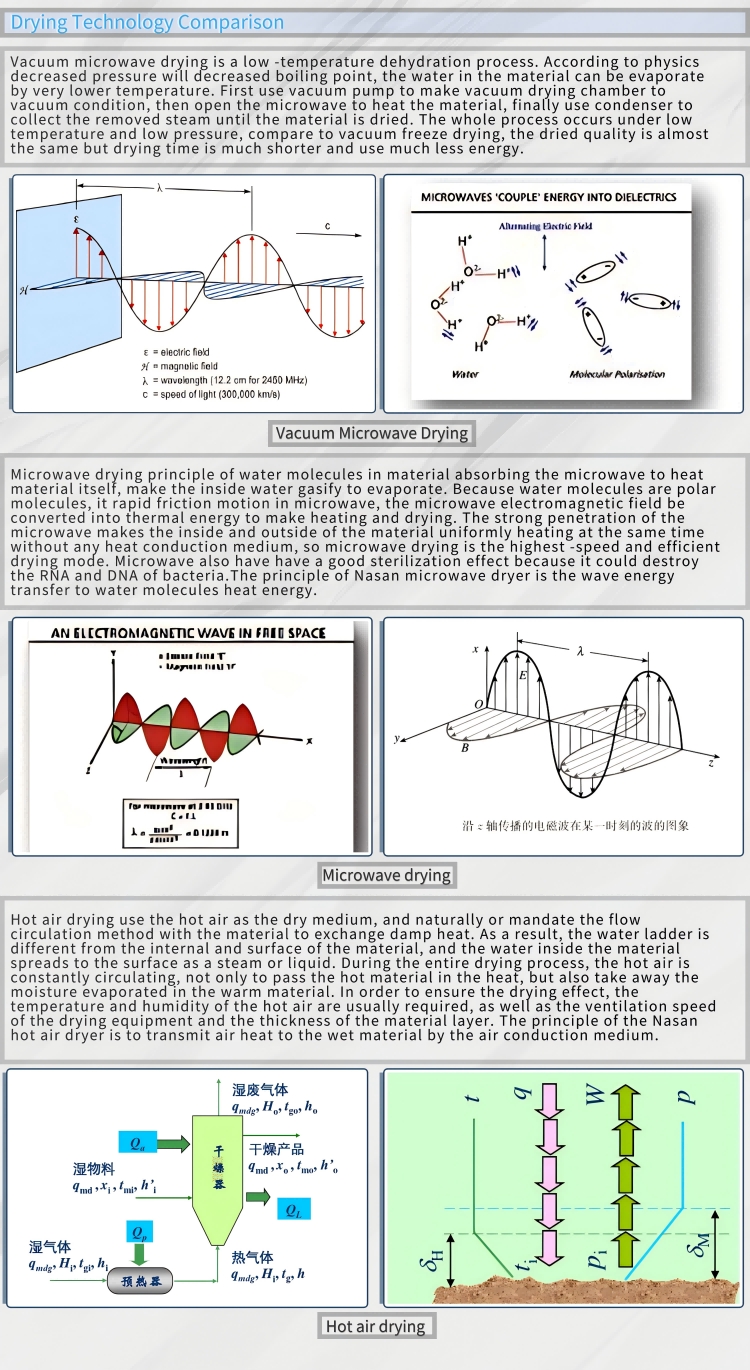

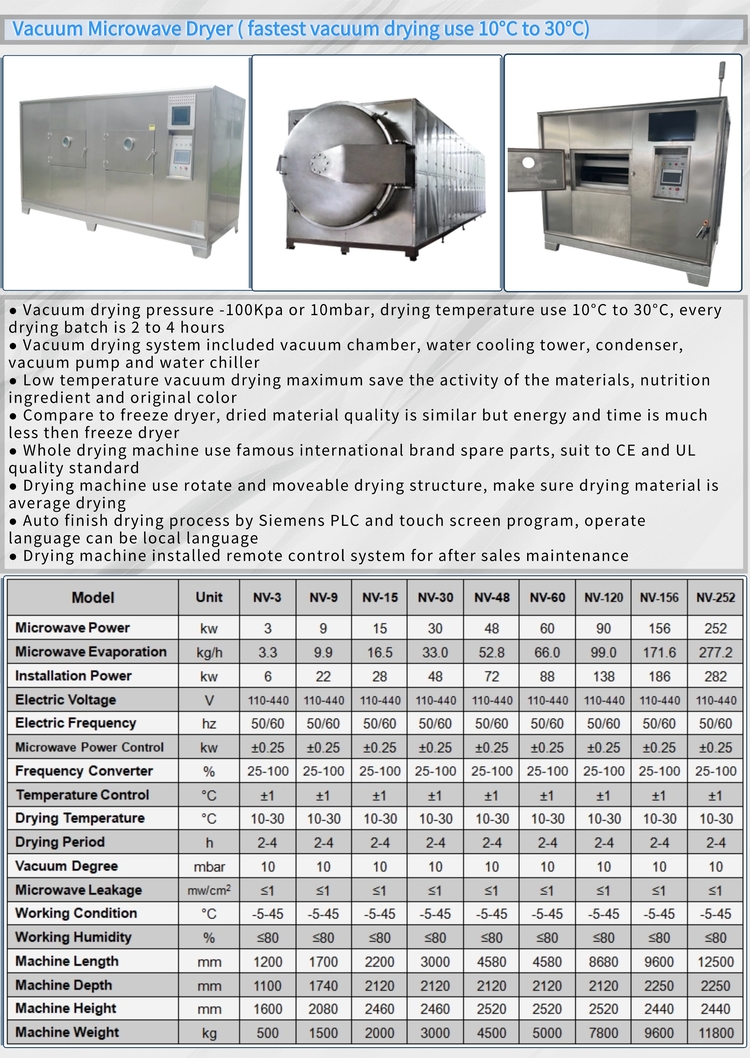

Vacuum microwave drying solves these issues with low-temperature, rapid moisture removal (preserves anthocyanins and polysaccharides) and internal, gentle heating (maintains cell structure), making it the gold standard for high-quality dried Lycium ruthenicum.

Industrial Considerations for Lycium ruthenicum Drying

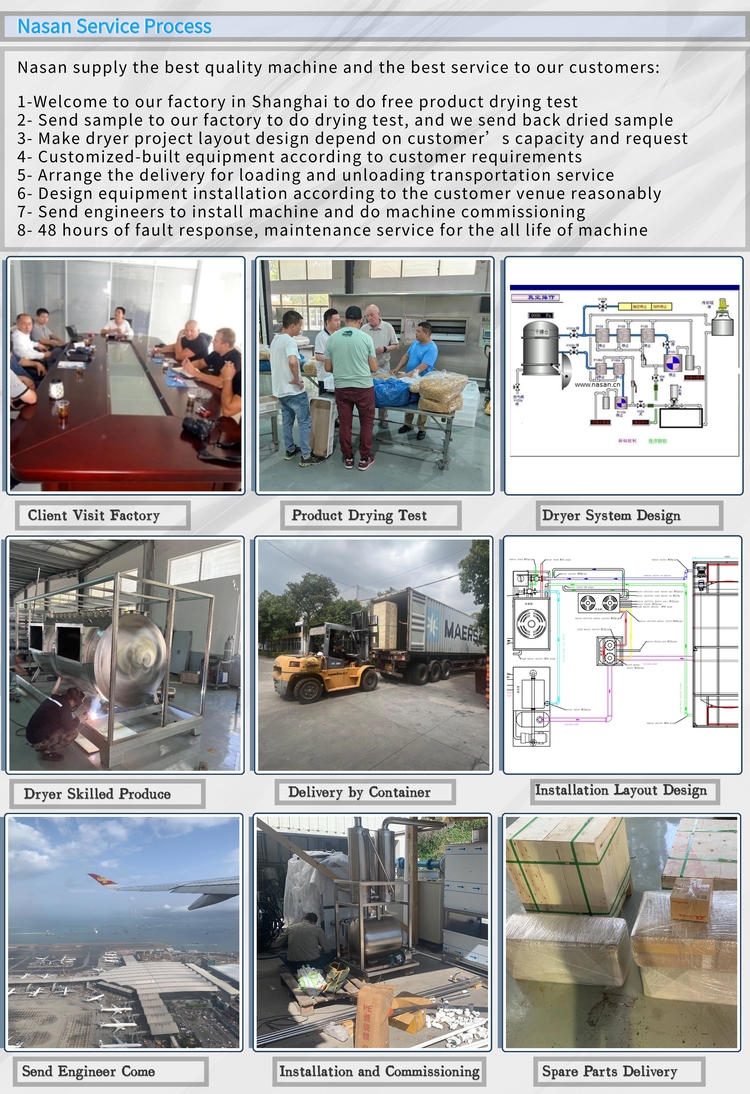

For manufacturers scaling up Lycium ruthenicum vacuum microwave drying, key factors to address include:

Anthocyanin Leakage Prevention: Avoid excessive water contact during cleaning/pretreatment—use spray rinsing instead of soaking. Monitor ascorbic acid solution concentration (replenish every 10 kg of berries to maintain stabilization).

Batch Uniformity: Sort berries by size before drying—smaller berries dry faster than larger ones, leading to uneven moisture if mixed. Use automated sieving systems for efficiency.

Energy Optimization: Use a two-stage power gradient:

Waste Reduction: Use “seconds” (berries with minor discoloration or size irregularities) for powder production—they are unsuitable for whole-berry sales but retain high anthocyanins for supplements.

In summary, vacuum microwave drying is the only technology that preserves Lycium ruthenicum’s most valuable attributes: deep anthocyanin-rich color, high polysaccharide content, and tender texture. Its ability to avoid nutrient loss and quality defects makes it essential for producers targeting premium health food and wellness markets.