A vacuum food microwave drying machine is a device that combines microwave heating technology with vacuum drying technology to dehydrate food. Here is a detailed introduction:

Working Principle

Microwave Penetrating Heating: Microwaves can penetrate the interior of food, directly acting on water molecules, causing them to vibrate at high frequency and generate heat, achieving uniform heating from the inside out. This is different from traditional drying methods that rely on surface heat conduction, which can easily lead to surface hardening and difficult internal moisture migration.

Vacuum Environment Reducing Boiling Point: In a vacuum environment, the boiling point of water is significantly reduced. For example, at -0.08 MPa, the boiling point of water is about 45°C. This allows the food to be dehydrated quickly at a low temperature, reducing the decomposition of heat-sensitive components. At the same time, the vacuum environment isolates oxygen, preventing the oxidation of substances in the food and maintaining the color and quality of the food.

Advantages

High - efficiency and Fast Drying: Microwave heating makes the inside and outside of the food heat up simultaneously, and the vacuum environment reduces the boiling point of water and the resistance of water migration, greatly increasing the evaporation rate. The comprehensive effect can shorten the drying time several times to dozens of times compared with traditional hot - air drying.

Low - temperature Drying to Retain Quality: The low - temperature vacuum environment (usually 40 - 60°C) can effectively avoid the damage and oxidative deterioration of heat - sensitive components such as vitamins, pigments, and flavor substances in food, and can maximally retain the natural color, flavor, nutritional value, and physiological activity components of the product.

Uniform Drying: The penetrability of microwaves enables uniform heating inside and outside the food, overcoming the problems of surface hardening and internal wet core in traditional drying. The vacuum environment promotes the rapid vaporization and expansion of water under low pressure, forming a porous and loose structure, which makes the rehydration of the product better.

Applications

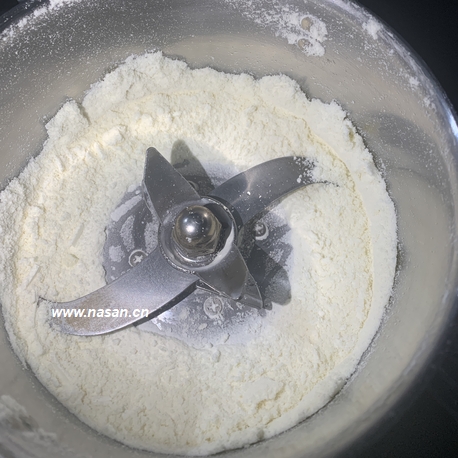

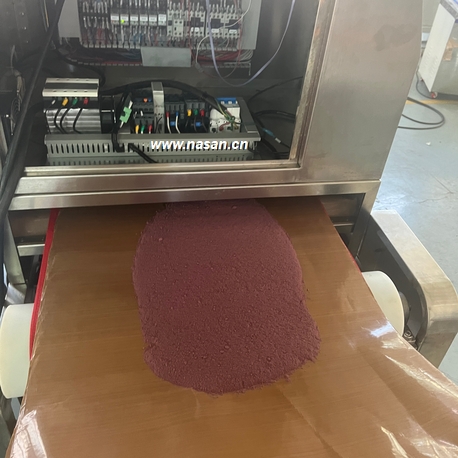

Food Industry: It is suitable for the drying of various fruits and vegetables, meat products, snack foods, dairy products, etc., especially for heat - sensitive foods such as fruit slices, dried fruits, beef jerky, and instant noodles.

Pharmaceutical Industry: Used for the drying of Chinese herbal medicines, pharmaceutical extracts, etc.

Chemical Industry: Applicable to the dehydration and drying of some chemical raw materials.