In today's fast-paced industrial landscape, the demand for efficient, reliable, and cost-effective sterilization methods has never been higher. Among the innovative solutions gaining traction, microwave sterilize technology stands out as a game-changer. This method leverages electromagnetic waves to eliminate microorganisms, offering a rapid and uniform alternative to traditional techniques like steam autoclaving or chemical treatments. The core principle behind microwave sterilize processes involves the agitation of water molecules within materials, generating heat that destroys bacteria, viruses, and spores without compromising product integrity. As industries from pharmaceuticals to food processing seek to enhance hygiene standards and operational efficiency, microwave sterilize systems are becoming indispensable. This article delves into the intricacies of industrial applications, equipment types, pricing factors, manufacturer selection, and common challenges, providing a comprehensive overview for businesses considering this advanced sterilization approach.

The adoption of microwave sterilize methods is driven by their ability to reduce processing times, lower energy consumption, and minimize chemical usage. Unlike conventional methods that may require prolonged exposure or harsh agents, microwave sterilize technology achieves sterilization in minutes, making it ideal for high-throughput environments. Moreover, it supports sustainability goals by reducing waste and energy footprints. As we explore the components and considerations involved, it's clear that microwave sterilize is not just a trend but a transformative force in industrial hygiene.

What is an Industrial Microwave Sterilizer?

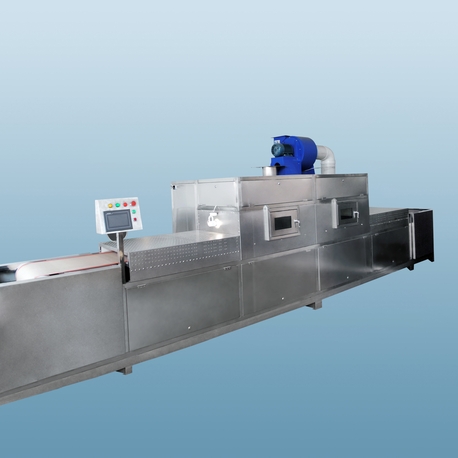

An industrial microwave sterilizer is a specialized device designed for large-scale sterilization tasks in sectors such as healthcare, food and beverage, and manufacturing. These systems utilize microwave energy to penetrate materials deeply, ensuring thorough decontamination without the need for external heat sources. The industrial microwave sterilizer typically consists of a magnetron (which generates microwaves), a chamber where items are placed, and control systems to regulate frequency and power. This setup allows for precise temperature control, which is crucial for sensitive products like medical devices or perishable goods.

The advantages of using an industrial microwave sterilizer include its scalability and versatility. For instance, in the pharmaceutical industry, it sterilizes packaging materials and equipment, while in food processing, it treats spices and ready-to-eat meals. The industrial microwave sterilizer also integrates with conveyor systems for continuous operation, boosting productivity. Key features often include automated controls, safety interlocks, and monitoring sensors to ensure consistent results. As businesses prioritize efficiency, the industrial microwave sterilizer has become a cornerstone of modern sterilization protocols, offering a blend of speed and reliability that traditional methods struggle to match.

Types of Microwave Sterilization Equipment

Microwave sterilization equipment encompasses a range of devices tailored to different industrial needs. These systems vary in size, capacity, and functionality, allowing organizations to select models that align with their specific requirements. Common types include batch sterilizers, continuous tunnel sterilizers, and modular units. Batch sterilizers, for example, are ideal for smaller loads or R&D settings, where items are processed in discrete cycles. In contrast, continuous tunnel sterilizers use conveyor belts to handle large volumes, making them suitable for production lines in food or pharmaceutical plants.

Another category within microwave sterilization equipment is the portable or benchtop unit, which offers flexibility for laboratories or small-scale operations. These devices often feature user-friendly interfaces and compact designs without sacrificing power. Additionally, specialized microwave sterilization equipment may include hybrid systems that combine microwaves with other technologies, such as UV light or steam, to enhance efficacy. For instance, in wastewater treatment, hybrid microwave sterilize systems can tackle resistant pathogens more effectively. When evaluating microwave sterilization equipment, factors like frequency (typically 2.45 GHz for industrial use), power output, and chamber design play critical roles in performance. Investing in the right microwave sterilization equipment can lead to significant cost savings and improved product quality, underscoring the importance of understanding these variations.

Factors Affecting Industrial Microwave Sterilizer Price

The industrial microwave sterilizer price is a key consideration for businesses planning to integrate this technology. Several elements influence the cost, starting with the system's capacity and power rating. High-capacity units designed for large-scale operations, such as those used in meat processing or hospital sterilization, command a higher industrial microwave sterilizer price due to their robust components and advanced features. Typically, prices can range from $10,000 for basic models to over $100,000 for custom, high-throughput systems. Another factor is the level of automation; fully automated industrial microwave sterilizer models with PLC controls and data logging capabilities tend to be more expensive but offer long-term savings through reduced labor costs.

Material construction also impacts the industrial microwave sterilizer price. Units made from stainless steel or other durable materials that resist corrosion and ensure hygiene come at a premium. Additionally, regulatory compliance, such as meeting FDA or CE standards, can add to the cost through certification and testing. Energy efficiency is another aspect; while energy-efficient models might have a higher upfront industrial microwave sterilizer price, they lower operational expenses over time. Businesses should also consider maintenance and warranty terms, as these affect the total cost of ownership. By analyzing these factors, companies can make informed decisions that balance budget constraints with performance needs, ensuring that the industrial microwave sterilizer price aligns with their strategic goals.

Choosing a Microwave Sterilization Machine Manufacturer

Selecting a reliable microwave sterilization machine manufacturer is crucial for ensuring equipment quality, support, and longevity. A reputable microwave sterilization machine manufacturer typically offers a portfolio of proven systems, backed by certifications like ISO 9001, which attest to their commitment to quality management. When evaluating a microwave sterilization machine manufacturer, consider their industry experience and client testimonials. For example, manufacturers with a track record in pharmaceutical or food sectors are likely to understand specific regulatory requirements, such as GMP (Good Manufacturing Practices).

Another aspect to assess is the microwave sterilization machine manufacturer's after-sales service, including technical support, spare parts availability, and training programs. A manufacturer that provides comprehensive maintenance contracts can minimize downtime and extend equipment life. Customization options are also important; some microwave sterilization machine manufacturer entities offer tailored solutions to fit unique production lines, which can enhance efficiency. Additionally, look for manufacturers who invest in R&D to incorporate the latest advancements in microwave sterilize technology, such as improved energy distribution or smart controls. By partnering with a trusted microwave sterilization machine manufacturer, businesses can mitigate risks and maximize the return on investment, ensuring that their sterilization processes remain cutting-edge.

Common Problems and Solutions in Microwave Sterilization

Despite its advantages, microwave sterilize technology can encounter issues that affect performance. One common problem is uneven heating, where certain areas of the load receive insufficient sterilization due to hot and cold spots. This often stems from improper load arrangement or suboptimal chamber design. To address this, users should follow manufacturer guidelines for loading patterns and consider systems with rotating turntables or stirrers that promote uniform energy distribution. Regular calibration of the industrial microwave sterilizer can also help maintain consistency.

Another issue involves material compatibility; some products, such as those with metal components or low moisture content, may not respond well to microwave sterilize processes, leading to damage or ineffective sterilization. Solutions include pre-testing materials in lab settings and adjusting power settings accordingly. Additionally, safety concerns like microwave leakage can arise if equipment is poorly maintained. Implementing routine inspections and using devices with built-in safety features, such as door seals and radiation monitors, can prevent this. Operational challenges, such as high energy consumption or frequent breakdowns, often relate to choosing low-quality microwave sterilization equipment. Investing in reliable systems from a reputable microwave sterilization machine manufacturer and training staff on proper usage can mitigate these problems. By proactively addressing these common issues, businesses can optimize their microwave sterilize operations and achieve consistent results.

In summary, microwave sterilize technology represents a significant leap forward in industrial sterilization, offering speed, efficiency, and environmental benefits. From understanding the role of an industrial microwave sterilizer to navigating the industrial microwave sterilizer price and selecting a dependable microwave sterilization machine manufacturer, businesses have numerous factors to consider. The diverse range of microwave sterilization equipment ensures that there is a solution for every need, while awareness of common problems empowers users to implement best practices. As industries continue to evolve, adopting microwave sterilize methods can enhance competitiveness and compliance. By investing in this innovative approach, organizations can not only improve their sterilization outcomes but also contribute to a safer, more sustainable future. Whether you're in food processing, healthcare, or manufacturing, now is the time to explore how microwave sterilize can transform your operations.