In the world of industrial processing, achieving absolute sterility is not just a goal—it's a stringent requirement. From pharmaceuticals to food production, the demand for efficient, reliable, and fast decontamination methods is higher than ever. While traditional methods like steam autoclaves and chemical fumigation have been the norm, a powerful technology has been steadily gaining ground: microwave sterilize systems. This isn't about reheating your lunch; it's about leveraging precise electromagnetic energy to achieve a new standard of cleanliness in industrial drying and sterilization. In this deep dive, we'll explore how this technology works and why it's revolutionizing commercial operations, with a look at how innovators like Nasan are integrating it into their advanced dryer systems.

How Does Microwave Sterilize Technology Actually Work?

The principle behind microwave sterilize processes is fundamentally different from conventional heat-based methods. Traditional systems heat the surface of an object and rely on conduction to transfer that heat inward. This is slow and can lead to uneven temperature distribution.

Industrial microwave sterilize systems use microwaves—a form of non-ionizing electromagnetic radiation—to agitate water molecules within the product or material. This agitation generates heat throughout the entire mass simultaneously in a process known as volumetric heating. The result is a rapid and uniform temperature rise that is lethal to microorganisms.

The critical factor for effective sterilization is the combination of temperature and time. A microwave sterilizer can quickly elevate the core temperature of a batch of spices, pharmaceutical powders, or medical garments to the required threshold (e.g., 121°C or more) and maintain it for the precise duration needed to destroy bacteria, viruses, fungi, and spores. This speed and precision are what set it apart.

The Top 7 Benefits of Using a Microwave Sterilizer in Your Production Line

Why are so many industries making the switch? The advantages of industrial microwave sterilize equipment are compelling.

Unmatched Speed and Efficiency: The volumetric heating effect reduces processing times by up to 50-70% compared to autoclaves. This translates directly to higher throughput and lower energy consumption per batch.

Superior Sterilization Quality: Because heating is uniform, there are no cold spots where microorganisms can survive. This ensures a consistent and guaranteed sterility assurance level (SAL).

Preservation of Product Integrity: For heat-sensitive materials like certain herbs or biological products, the rapid process minimizes thermal degradation. The product is sterilized without being cooked or losing its essential properties.

Enhanced Energy Efficiency: Microwave sterilize systems convert electricity directly into thermal energy within the product, unlike autoclaves that waste energy heating large volumes of water and steel chambers.

Dry and Cool-to-Touch Output: Unlike steam sterilization, the process doesn't introduce moisture. Materials come out dry and can often be handled or packaged immediately, saving additional drying steps.

Environmentally Friendly Operation: This technology eliminates the need for large quantities of water and harsh chemical sterilants, reducing your plant's environmental footprint.

Precision Process Control: Modern systems, like those developed by Nasan, offer sophisticated control systems that allow operators to set exact time-temperature profiles, ensuring repeatable results batch after batch.

Key Industries Transformed by Microwave Sterilization

The application of microwave sterilize technology is broad and impactful across several key sectors.

Pharmaceutical and Nutraceutical: Ideal for sterilizing powders, granules, and containers without compromising the active ingredients. The dry, closed system also helps maintain a cleanroom environment.

Food and Spice Processing: A game-changer for decontaminating spices, herbs, and ready-to-eat ingredients. It effectively eliminates pathogens like Salmonella and E. coli while preserving flavor and color far better than steam or ethylene oxide.

Medical and Healthcare: Used for sterilizing single-use medical devices, gowns, and packaging materials. The speed is crucial for just-in-time manufacturing and supply.

Waste Management: Microwave sterilize systems can treat biomedical waste, rendering it safe for disposal by destroying all viable pathogens.

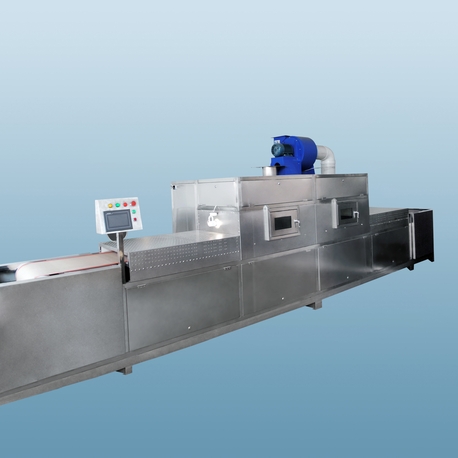

Integrating a Microwave Sterilizer with Your Industrial Drying Process

For many facilities, the most logical step is to integrate sterilization directly into the drying line. An industrial dryer equipped with microwave sterilize capabilities can perform two critical unit operations in one pass. For instance, a wet pharmaceutical powder can be dried to a specific moisture content and then immediately subjected to a microwave sterilize cycle before being discharged into sterile containers. This seamless integration reduces handling, minimizes the risk of contamination, and slashes total processing time. Companies like Nasan specialize in designing such integrated solutions, tailoring the equipment to the specific thermal and sterility requirements of the product.

Common Questions About Industrial Microwave Sterilize Technology (FAQs)

Q1: Is microwave sterilization as effective as autoclaving?

A1: Yes, when properly calibrated and validated, a microwave sterilizer is just as effective, often more so. Its ability to heat uniformly eliminates the risk of cold spots, a potential issue in autoclaves. It achieves the same sterility assurance levels (SAL of 10^-6) required by regulatory bodies.

Q2: What types of materials can be processed in a microwave sterilizer?

A2: A wide variety, including powders, granules, textiles, certain plastics, and glassware. Materials that are transparent to microwaves or contain no moisture (like pure metals) are not suitable. A reputable provider like Nasan can conduct product trials to determine suitability.

Q3: How is the process controlled and validated?

A3: Industrial systems are equipped with multiple temperature sensors and pressure controls. The sterilization cycle is validated using biological indicators (e.g., spore strips) and detailed mapping to ensure every part of the load reaches the required temperature for the necessary time.

Q4: Are there any safety concerns with industrial microwave systems?

A4: Commercial-grade microwave sterilize units are fully shielded, much like a commercial oven, to prevent any leakage of radiation. Interlock systems ensure the unit cannot operate while open, making them safe for industrial environments.

Q5: What is the typical maintenance requirement for this equipment?

A5: Maintenance is generally straightforward. It primarily involves routine checks of the magnetron (the component that generates microwaves), waveguides, and door seals. Compared to autoclaves, they have fewer mechanical parts and no large pressure vessel inspections, often leading to lower long-term maintenance costs.

The shift towards microwave sterilize technology in industrial drying represents a significant leap forward in efficiency, product quality, and operational control. It addresses the limitations of older methods while offering a cleaner, faster, and more precise solution. As industries continue to push for higher standards and greener practices, the role of this advanced technology will only grow. For businesses looking to future-proof their sterilization processes, exploring the integrated drying and microwave sterilize solutions from forward-thinking engineers, such as the team at Nasan, is a logical and profitable next step.