| Type | Working Principle | Advantages | Disadvantages | Suitable Scenarios |

|---|

| Hot Air Dryer | Uses heated, low-humidity air (40-60°C) to circulate around mushrooms, evaporating surface moisture. Airflow is controlled (e.g., cross-flow, parallel-flow) for uniformity. | - Low equipment cost- Easy to operate- Gentle drying for most mushroom varieties- Scalable (small batch to industrial) | - Longer drying time (8-24 hours)- Risk of surface hardening if airflow is poor | Household use, small farms, medium-scale processing (e.g., oyster, button mushrooms). |

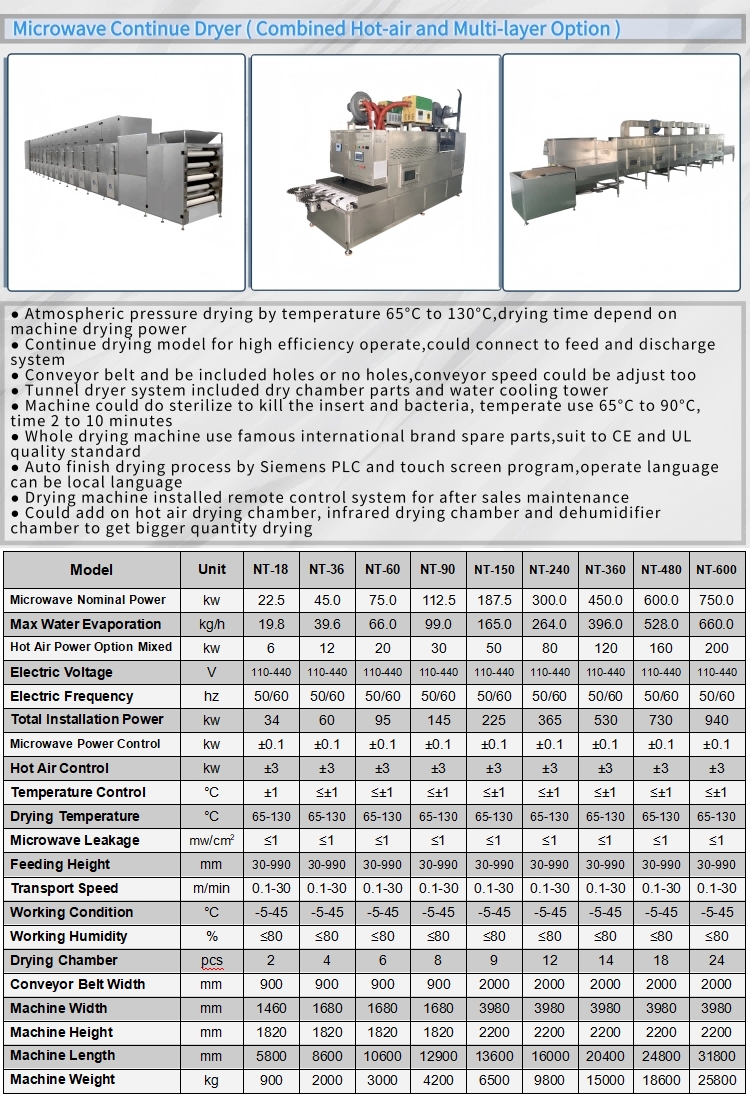

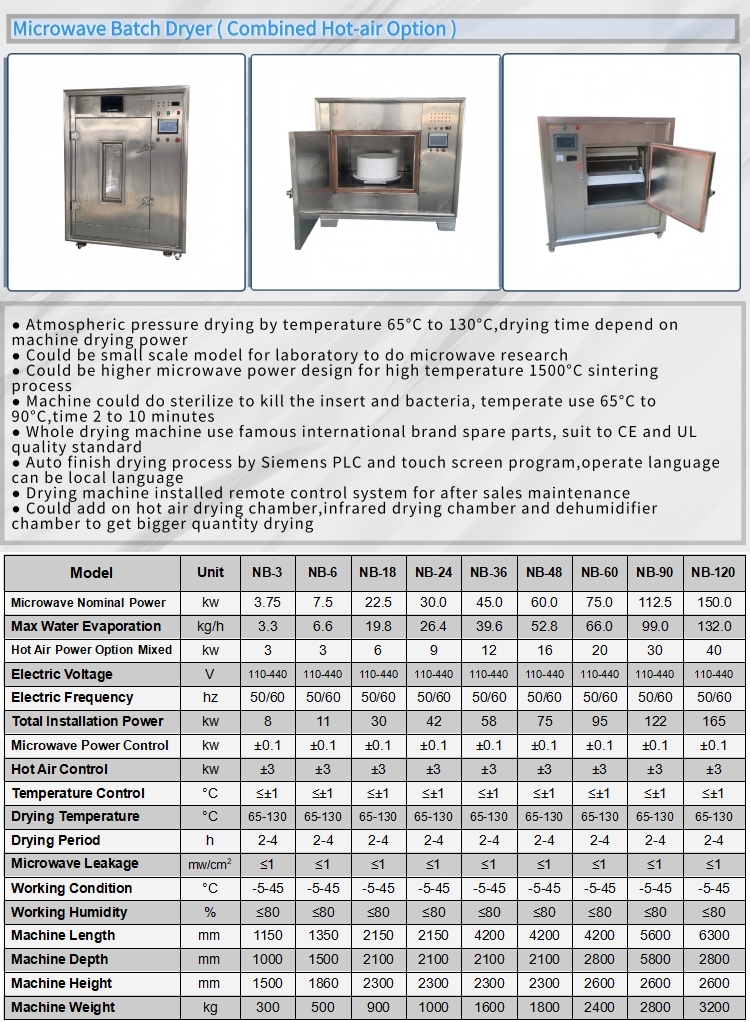

| Microwave Dryer | Emits microwave energy (2.45 GHz) to excite water molecules inside mushrooms, heating from inside out and accelerating moisture evaporation. | - Fast drying (1-3 hours, 1/5 of hot air time)- Uniform heating (avoids wet cores)- Better nutrient retention (short heat exposure) | - Higher energy consumption than hot air- Possible textural changes (slightly harder) if power is misadjusted | Small-batch processing, urgent production (e.g., fresh shiitake). |

| Vacuum Microwave Dryer | Combines microwave heating with a vacuum environment (reduces water boiling point to 40-50°C). Moisture evaporates quickly at low temperatures, and vapor is instantly removed by the vacuum system. | - Best quality retention: Low temp preserves nutrients, color, and flavor- No oxidation (vacuum isolates oxygen)- Porous final product (easy rehydration) | - High equipment cost- Complex maintenance- Lower throughput than hot air | High-value mushrooms (e.g., reishi, cordyceps, wild porcini) where quality is critical; pharmaceutical-grade mushroom extracts. |

| Freeze Dryer | Freezes mushrooms to -40°C (converting moisture to ice), then uses a vacuum to sublime ice directly into vapor (no liquid phase). | - Top-tier quality: Retains 95%+ nutrients, original shape, and fresh flavor- Excellent rehydration (absorbs water quickly to mimic fresh mushrooms) | - Extremely high cost (equipment and energy)- Slow drying (12-48 hours)- Low production capacity | Premium products (e.g., freeze-dried mushroom snacks, instant soup ingredients, high-end culinary mushrooms). |