In the competitive landscape of industrial manufacturing, efficiency is the primary driver of profitability. Traditional dehydration methods often create a bottleneck in production lines. They consume vast amounts of time and energy while frequently degrading the quality of the final product.

To overcome these limitations, advanced facilities are adopting vacuum microwave drying. This technology represents a significant leap forward in dehydration science. It combines the speed of radiative heating with the low-temperature benefits of a vacuum environment.

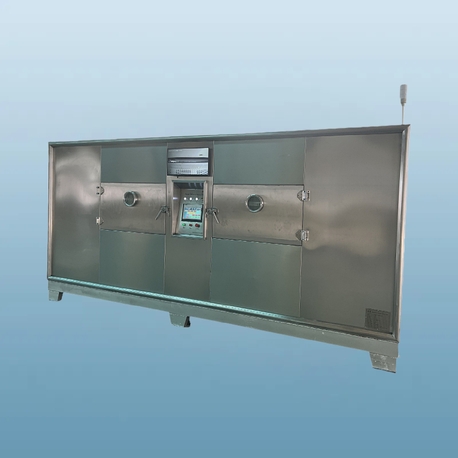

Companies like Nasan have recognized the shift toward this technology. They provide equipment that addresses the specific needs of the food, pharmaceutical, and chemical industries. By understanding the mechanics and benefits of this process, manufacturers can make informed decisions about upgrading their production lines.

The Mechanics of Vacuum Microwave Drying

The fundamental principle behind vacuum microwave drying is the manipulation of the boiling point of water. At standard atmospheric pressure, water boils at 100°C (212°F). However, inside a vacuum chamber, the atmospheric pressure is significantly reduced.

When the pressure drops, the boiling point of water decreases proportionally. Depending on the vacuum level, water can vaporize at temperatures as low as 30°C to 40°C. This allows for rapid evaporation without subjecting the product to high thermal stress.

While the vacuum lowers the boiling point, microwave energy provides the heat source. Unlike convection ovens that heat from the outside in, microwaves penetrate the material. They cause water molecules within the product to oscillate, generating heat volumetrically.

This internal heating pushes moisture to the surface where the vacuum environment instantly removes it. The result is a drying rate that is drastically faster than conventional hot air systems.

Key Advantages for Industrial Processors

The primary advantage of this technology is speed. A process that might take 24 hours in a hot air tunnel can often be completed in less than an hour using vacuum microwave drying. This allows for "Just-In-Time" manufacturing and reduces the need for massive storage space for drying inventory.

Energy efficiency is another critical factor. Because the energy is targeted directly at the water molecules, there is very little wasted heat. The equipment does not need to heat the air inside the chamber or the massive metal structure, only the product itself.

Quality preservation is superior in this method. Since the process occurs in a vacuum, oxygen is minimal. This prevents oxidation reactions that typically ruin the color and flavor of food products. Vivid colors and fresh aromatic compounds are retained.

Furthermore, the low temperature prevents the thermal degradation of heat-sensitive components. Vitamins, enzymes, and active pharmaceutical ingredients remain potent, which is essential for high-value products.

The Puffing Effect and Texture Control

One unique characteristic of vacuum microwave drying is the "puffing" effect. This is particularly valuable in the snack food industry. As the internal water turns to vapor rapidly, it creates an outward pressure within the food structure.

This pressure expands the product before the structure sets. The result is a crunchy, porous texture that is highly desirable in fruit and vegetable chips. Traditional air drying often results in a hard, shrunken product that is difficult to chew.

Manufacturers can control this texture by adjusting the power density and vacuum levels. A higher power density creates a more significant expansion, while a gentler setting creates a denser product.

This versatility allows a single machine to produce a wide range of product textures, from crispy apple chips to chewy dried mangoes, simply by changing the program parameters.

Applications in the Food Industry

The food sector is the largest adopter of vacuum microwave drying. It is used extensively for fruits, vegetables, meats, and seafood. High-value crops like berries and tropical fruits benefit immensely from the color retention.

In the spice and herb industry, the retention of volatile oils is crucial. Air drying drives off these aromatic compounds, resulting in a flat flavor. Microwave vacuum technology locks these oils inside the plant matrix.

Instant foods also rely on this technology. Ingredients for instant soups and noodles need to rehydrate quickly. The porous structure created by the microwave process allows hot water to penetrate the food rapidly, ensuring a good texture for the consumer.

Seafood processors use it to dry shrimp and scallops. The low temperature prevents the proteins from denaturing excessively, maintaining the sweet flavor and natural texture of the seafood.

Pharmaceutical and Chemical Use Cases

Beyond food, the pharmaceutical industry utilizes vacuum microwave drying for granulations and powders. Many drugs are heat-labile, meaning they lose effectiveness when exposed to high temperatures.

This technology allows for the drying of wet granules at safe temperatures. It ensures consistent moisture content, which is critical for tablet compression and shelf stability.

In the chemical industry, it is used to dry pastes, sludges, and specialized polymers. The precise control over moisture content helps in achieving the exact specifications required for chemical reactions or final product formulation.

Extracts and concentrates, such as herbal medicine extracts, are difficult to dry because they are sticky and high in sugar. This technology handles these viscous materials effectively, drying them into a brittle form that can be easily milled into powder.

Comparing to Freeze Drying

Freeze drying (lyophilization) is often considered the gold standard for quality. However, it is an extremely slow and expensive process. A freeze-drying cycle can take 24 to 72 hours.

Vacuum microwave drying sits in a strategic middle ground. It produces quality that is very close to freeze-drying—retaining shape and color—but does so at a fraction of the cost and time.

For many commercial products, the marginal quality difference of freeze-drying does not justify the massive increase in operating costs. Microwave vacuum technology offers a more commercially viable solution for mass-market products.

Additionally, freeze-dried products can sometimes be too brittle. Microwave vacuum dried products have a slightly more robust structure, making them less prone to crumbling during packaging and transport.

Technical Considerations for Equipment Selection

When selecting a dryer, the magnetron quality is paramount. Industrial magnetrons must be durable and provide a stable frequency output. Brands like Nasan integrate high-grade components to ensure continuous operation without frequent downtime.

The vacuum system must be robust. A liquid ring vacuum pump is commonly used for its ability to handle moisture loads. The seal integrity of the chamber is vital to maintain the low pressure required for the process.

Automation plays a huge role. Modern systems utilize Programmable Logic Controllers (PLC). These allow operators to create multi-stage drying recipes. For example, a recipe might start with high power to remove free water and switch to low power for bound water.

Uniformity of heating is a technical challenge. Good equipment uses a combination of rotating turntables or moving belts and mode stirrers. These features ensure that the microwave energy is distributed deeply and evenly throughout the batch.

Hygiene and Maintenance

Sanitation is critical, especially in food and pharma. The drying chamber should be constructed of food-grade stainless steel (usually 304 or 316). The design must avoid dead corners where material can accumulate.

Vacuum microwave drying systems are inherently cleaner than air dryers. Because there is no constant airflow bringing in dust or bacteria from the environment, the product remains sterile. The microwaves themselves also have a sterilization effect, reducing the microbial load.

Maintenance involves checking the magnetrons and the cooling system. Magnetrons generate heat and are typically water-cooled or air-cooled. Ensuring the cooling system functions correctly extends the life of the microwave generators.

The conveyor belts in continuous systems need to be food-safe and transparent to microwaves. PTFE (Teflon) belts are standard. They are non-stick and easy to clean, but they must be inspected regularly for wear.

Energy Sustainability

Sustainability is a growing concern for global industries. Traditional thermal drying is carbon-intensive. Vacuum microwave drying supports green manufacturing goals by reducing the carbon footprint per kilogram of product.

Since the process is faster, the equipment runs for fewer hours to produce the same volume. The electrical efficiency of modern microwave generators has also improved, converting a higher percentage of input electricity into microwave energy.

Some facilities couple these dryers with renewable energy sources. Since they run on electricity rather than burning fossil fuels directly (like gas ovens), they are easier to integrate into a solar or wind-powered grid.

Future Trends in Dehydration

The future of industrial drying lies in hybrid technologies. We are seeing systems that combine microwave vacuum with other energy sources, such as infrared or ultrasonic assistance, to further optimize the process.

Smart sensors are becoming standard. Real-time monitoring of product temperature and moisture content allows the machine to self-adjust. This eliminates the guesswork and ensures every batch meets quality standards.

As the demand for premium dried snacks and high-quality ingredients grows, the market share of this technology will expand. It is moving from a niche technology to a mainstream manufacturing requirement.

The shift toward vacuum microwave drying is driven by the need for better products produced faster. It solves the age-old compromise between quality and cost in the dehydration industry.

Manufacturers who adopt this technology gain a competitive edge. They can offer products with better visual appeal, higher nutritional value, and superior texture. Simultaneously, they reduce their operational costs through energy savings and faster throughput.

With reliable equipment providers like Nasan delivering robust industrial solutions, implementing this technology is more accessible than ever. It represents a smart investment in the future of food and pharmaceutical processing.

Frequently Asked Questions (FAQ)

Q1: How does vacuum microwave drying differ from a standard microwave oven?

A1: While both use microwave energy, industrial vacuum microwave drying operates under low pressure. This lowers the boiling point of water, allowing drying to occur at much lower temperatures (30-40°C) compared to a home microwave. Additionally, industrial units use precise PLCs, rotating trays or belts, and industrial-grade magnetrons for uniform drying, which is not possible in standard ovens.

Q2: Is this technology suitable for liquids and pastes?

A2: Yes, it is highly effective for liquids and pastes. Because the vacuum lowers the boiling point, viscous materials can be dried without burning or forming a hard crust. It is commonly used to dry fruit concentrates, chemical pastes, and herbal extracts into powders.

Q3: Does the process kill bacteria and improve food safety?

A3: Yes. The combination of thermal energy and the specific effects of microwaves helps to reduce the microbial load significantly. The process takes place in a sealed, clean chamber, preventing re-contamination from the environment, which is a common risk in open-air drying.

Q4: What is the energy consumption compared to freeze drying?

A4: Vacuum microwave drying is generally much more energy-efficient than freeze drying. Freeze drying requires freezing the product first and then maintaining a deep vacuum for a long period (24+ hours). Microwave vacuum drying is a rapid process, often finishing in under an hour, which drastically reduces the total energy required per batch.

Q5: Can the equipment handle metal trays?

A5: No, metal reflects microwaves and can cause arcing, which damages the machine. Industrial microwave dryers use specialized trays or belts made from microwave-transparent materials like polypropylene, PTFE (Teflon), or PEEK. These materials allow the energy to pass through to the product and are food-safe.