The seafood processing industry demands consistency, hygiene, and efficiency. Traditional methods of preserving fish no longer meet the strict standards required by global markets. Weather dependency and contamination risks make outdoor drying obsolete for commercial operations.

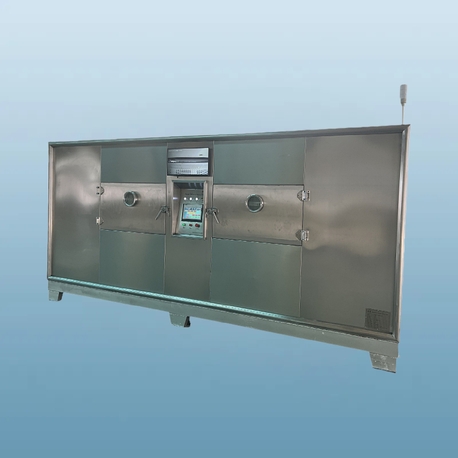

Modern processing facilities now rely on advanced mechanical solutions. A high-quality fish dryer provides the precision needed to remove moisture effectively without compromising the nutritional value of the product. Industrial-grade equipment ensures that processors can scale their operations while maintaining strict quality control.

Brands like Nasan have set high standards in the commercial drying sector. Their equipment helps industrial processors achieve optimal moisture levels while reducing energy consumption. In this article, we examine the functionality, benefits, and technical specifications of modern industrial drying systems for the seafood sector.

What is a Commercial Fish Dryer?

A commercial fish dryer is a specialized piece of industrial equipment designed to remove water content from raw seafood. It uses controlled thermal energy and airflow to dehydrate the product safely.

Unlike standard ovens, these machines operate at specific, often lower temperatures. This prevents the fish from cooking during the dehydration process. The goal is to remove moisture from the deep layers of the fish flesh, extending its shelf life.

Industrial dryers come in various configurations, including cabinet dryers, tunnel dryers, and continuous belt dryers. The choice depends on the daily production volume and the specific type of fish being processed.

Inside the chamber, a combination of circulation fans and dehumidifiers works continuously. They extract the saturated air and replace it with dry air, creating a consistent environment that traditional open-air methods cannot replicate.

The Financial Benefits of Using a Fish Dryer

Investing in a commercial fish dryer directly impacts the bottom line of a processing facility. The primary financial benefit comes from waste reduction. Traditional drying methods often result in high spoilage rates due to insect infestation, dust, or sudden rainfall.

Mechanical drying eliminates these environmental risks entirely. Processors can calculate their exact yield without factoring in weather-related losses. This predictability allows for better supply chain management and contract fulfillment with distributors.

Additionally, a modern fish dryer operates with significant energy efficiency. Advanced heat pump technology recycles thermal energy within the drying chamber. This reduces the electricity load required to maintain drying temperatures, lowering monthly utility costs.

Labor costs also decrease. Automated drying systems require minimal human intervention. Workers only need to load the trays and set the parameters on the control panel. The machine handles the entire dehydration cycle automatically.

Key Technologies in Modern Seafood Dehydration

The international industrial drying market relies heavily on heat pump technology. A heat pump fish dryer functions by absorbing heat from the surrounding air and transferring it to the drying chamber.

This method is highly effective for seafood because it allows for low-temperature drying. Low temperatures (usually between 20°C and 40°C) preserve the proteins, fatty acids, and natural colors of the fish. High-temperature drying can denature proteins and lead to an unappealing, brittle texture.

Closed-loop moisture removal is another critical technology. In a closed-loop system, no external air enters the chamber, and no internal air escapes. The moisture evaporated from the fish condenses on cold coils and drains out as liquid water.

Leading manufacturers in the sector, such as Nasan, utilize these closed-loop systems to ensure maximum energy retention and strict environmental hygiene. The closed environment guarantees that no airborne pathogens or pollutants can reach the seafood.

Finally, Programmable Logic Controllers (PLC) allow operators to set multi-stage drying profiles. Different stages of dehydration require different temperatures and humidity levels. PLC touchscreens make it easy to program these shifts automatically.

Comparing Mechanical Drying to Traditional Sun Drying

Sun drying has been used for centuries, but it falls short in a commercial industrial setting. The primary drawback of sun drying is its lack of control.

Temperature and humidity fluctuate throughout the day. This inconsistency leads to uneven drying. The outer layer of the fish may dry too quickly, forming a hard crust that traps moisture inside, a phenomenon known as case hardening.

A mechanical fish dryer solves this problem. The airflow is directed uniformly across all trays. Moisture is drawn out at a steady rate, ensuring the core of the fish reaches the target moisture content.

Furthermore, regulatory bodies like the FDA and European food safety agencies enforce strict guidelines on seafood processing. Sun-dried products often fail to meet the microbial limits required for export. Closed-chamber mechanical drying complies with Hazard Analysis and Critical Control Point (HACCP) standards.

Key Considerations for Selecting Industrial Drying Equipment

When purchasing a fish dryer, facility managers must evaluate several technical criteria. Capacity is the first factor. Dryers are rated by the amount of wet product they can hold per batch, ranging from a few hundred kilograms to several tons.

Material construction is critical in seafood processing due to the corrosive nature of salt and moisture. The interior chamber, trays, and trolleys must be constructed from food-grade stainless steel, typically 304 or 316-grade.

Airflow distribution design determines the consistency of the final product. A top-tier fish dryer uses a combination of horizontal and vertical airflow to ensure that trays at the top of the rack dry at the same speed as those at the bottom.

Energy source flexibility is also important. While electric heat pumps are popular, some industrial setups may prefer systems that integrate with existing steam boilers or biomass furnaces.

Applications Across Different Fish Species

A versatile fish dryer can process a wide variety of marine products. Each species requires a unique drying protocol based on its fat content and thickness.

For example, small, oily fish like anchovies require a gentle, lower-temperature drying process to prevent lipid oxidation, which causes rancidity.

Larger fish, such as cod or tilapia, are usually filleted or split before entering the chamber. These require higher initial temperatures to surface-dry the flesh, followed by a longer, lower-temperature phase to remove deep moisture.

Beyond finfish, commercial dryers are extensively used for sea cucumbers, shrimp, squids, and seaweeds. The ability to adjust humidity and temperature profiles makes a single machine suitable for an entire catalog of seafood products.

Maintenance and Hygiene Standards

Industrial processing equipment must be easy to clean. Fish processing generates scales, oils, and organic residues. A commercial fish dryer should feature smooth internal surfaces with minimal crevices where bacteria can harbor.

Wash-down capabilities are essential. The machine should allow operators to power-wash the interior between batches without damaging the electrical components.

Routine maintenance on heat pump dryers is relatively minimal. It involves checking refrigerant levels, cleaning air filters, and inspecting the door seals for air leaks. Proper maintenance ensures the equipment operates at peak efficiency for years.

Transitioning from traditional methods to mechanical dehydration is a necessary step for any scaling seafood enterprise. The predictability, hygiene, and product quality offered by modern equipment are unmatched.

An industrial fish dryer provides the precise control needed to meet strict international food safety standards. By investing in efficient technology, processors can reduce waste, lower their energy consumption, and increase their overall profit margins.

With reliable systems from trusted industry names like Nasan, commercial facilities can secure their place in the global market, delivering perfectly preserved seafood products consistently.

Frequently Asked Questions (FAQ)

Q1: What is the average drying time for fish in a commercial dryer?

A1: Drying time depends on the species, thickness, and desired final moisture content. Small fish like anchovies can dry in 8 to 12 hours. Thicker fillets or whole larger fish may require 18 to 36 hours. Using a modern fish dryer, this time is significantly faster and more consistent than traditional methods.

Q2: Does a mechanical fish dryer consume a lot of electricity?

A2: Modern industrial dryers are highly energy-efficient. Heat pump technology consumes about 30% to 40% of the energy used by traditional electric heating elements. They recover and reuse latent heat from the moisture evaporation, making them cost-effective for large-scale operations.

Q3: Can a single machine be used for both fish and other food products?

A3: Yes, a commercial fish dryer is highly versatile. By adjusting the temperature and humidity settings on the control panel, the same machine can dehydrate fruits, vegetables, meat, and herbs. However, thorough cleaning is required between different product types to prevent cross-contamination of odors.

Q4: How does mechanical drying improve food safety?

A4: Mechanical drying takes place in a closed, sanitized chamber. This eliminates exposure to flies, dust, bird droppings, and airborne pollutants. Furthermore, the precise temperature control prevents the growth of bacteria and molds that thrive in slow, outdoor drying conditions.

Q5: What moisture content is ideal for dried fish?

A5: The target moisture content varies by market requirements. For heavily salted dried fish, a moisture content of 35% to 40% is common. For long-term storage and export without refrigeration, the moisture content is typically reduced to between 15% and 20% to completely inhibit microbial activity.