In today's fast-paced industrial landscape, efficiency and reliability in drying processes are paramount for businesses aiming to maintain a competitive edge. Among the various drying solutions available, the tunnel dryer stands out as a versatile and effective system used across numerous sectors. This article delves into the intricacies of tunnel dryers, focusing on their industrial applications, key players in manufacturing, and how to identify the best options for your needs. We will explore the role of an industrial tunnel dryer, the importance of selecting a reputable tunnel dryer manufacturer, the benefits of partnering with a continuous dryer OEM, and what defines the best tunnel dryer in the market. By understanding these aspects, you can make informed decisions to optimize your production lines and enhance overall operational efficiency.

What is a Tunnel Dryer?

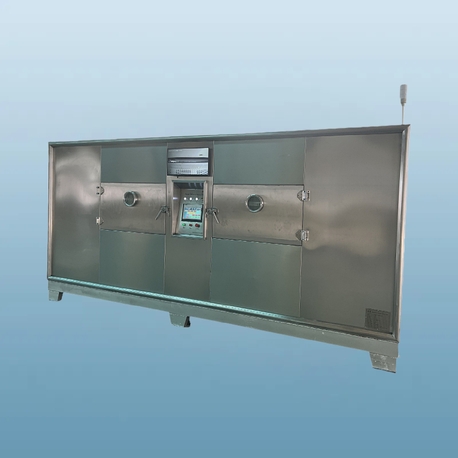

A tunnel dryer is a continuous drying system designed to handle large volumes of materials by passing them through a long, enclosed tunnel where controlled temperature and airflow facilitate moisture removal. This type of dryer is widely used in industries such as food processing, ceramics, textiles, and chemicals due to its ability to maintain consistent product quality and high throughput. The basic design involves a conveyor system that transports goods through different zones within the tunnel, each with specific temperature and humidity settings. This allows for gradual and uniform drying, reducing the risk of damage or uneven results. As a result, tunnel dryers are favored for their scalability and adaptability to various product types, making them a cornerstone in modern industrial operations.

The concept of a tunnel dryer has evolved over decades, incorporating advanced technologies like automated controls and energy recovery systems. Unlike batch dryers, which process materials in separate loads, a tunnel dryer operates continuously, enabling non-stop production cycles. This continuity is crucial for industries with high-demand outputs, as it minimizes downtime and maximizes resource utilization. Whether you're dealing with fragile food items or robust industrial components, a well-designed tunnel dryer can be tailored to meet specific requirements, ensuring optimal performance and product integrity.

How Industrial Tunnel Dryers Function

An industrial tunnel dryer is engineered for heavy-duty applications, where precision and durability are essential. The operation begins with the loading of wet materials onto a conveyor belt, which moves them through the tunnel at a controlled speed. Inside, heated air or other drying mediums are circulated using fans and heaters, creating a uniform environment that extracts moisture efficiently. The tunnel is typically divided into sections, allowing for staged drying where temperature and humidity can be adjusted to suit the material's properties. This zoning capability is a key feature of an industrial tunnel dryer, as it prevents overheating and ensures that sensitive products, such as pharmaceuticals or agricultural goods, are dried without compromising their quality.

The efficiency of an industrial tunnel dryer hinges on its ability to maintain consistent conditions throughout the process. Advanced models incorporate sensors and IoT technology to monitor parameters in real-time, enabling automatic adjustments for optimal performance. This not only improves drying accuracy but also reduces energy consumption, aligning with sustainability goals. Moreover, the continuous nature of these systems means that they can integrate seamlessly into existing production lines, supporting just-in-time manufacturing practices. For businesses looking to scale up, an industrial tunnel dryer offers a reliable solution that can handle increased volumes without significant modifications, making it a worthwhile investment for long-term growth.

Key Benefits of Using a Tunnel Dryer

The adoption of a tunnel dryer brings numerous advantages to industrial operations, starting with enhanced productivity. By enabling continuous processing, these dryers eliminate the bottlenecks associated with batch systems, leading to higher output rates and reduced labor costs. Additionally, the uniform drying conditions minimize product loss due to spoilage or defects, which is critical in industries like food and beverages where quality standards are stringent. Another significant benefit is energy efficiency; modern tunnel dryers often feature heat recovery systems that reuse waste energy, lowering operational expenses and environmental impact.

When it comes to versatility, a tunnel dryer excels in handling a wide range of materials, from powders and granules to large pieces. This flexibility allows businesses to use the same equipment for multiple product lines, maximizing return on investment. Furthermore, the robust construction of an industrial tunnel dryer ensures longevity and minimal maintenance, even in harsh environments. By partnering with a skilled tunnel dryer manufacturer, companies can customize these systems to address specific challenges, such as handling abrasive materials or operating in high-humidity conditions. Overall, the best tunnel dryer models combine reliability with innovation, providing a competitive advantage in today's market.

Applications in Various Industries

Tunnel dryers are indispensable in numerous sectors, thanks to their adaptability and efficiency. In the food industry, for instance, they are used to dry fruits, vegetables, grains, and snacks, preserving nutrients and extending shelf life. The controlled environment of an industrial tunnel dryer prevents contamination and ensures compliance with food safety regulations. Similarly, in the pharmaceutical sector, these dryers play a vital role in processing tablets and granules, where precise moisture control is necessary to maintain efficacy and stability.

The ceramics and building materials industries also rely heavily on tunnel dryers for curing tiles, bricks, and other components. The gradual drying process reduces cracking and warping, resulting in higher-quality end products. In textiles, tunnel dryers are employed to finish fabrics, removing moisture after dyeing or washing without causing shrinkage or damage. Additionally, chemical plants use these systems to dry pigments, polymers, and other compounds, where consistency is crucial for product performance. By understanding the specific needs of each application, a continuous dryer OEM can design solutions that optimize outcomes, whether it's through customized airflow patterns or specialized materials for the tunnel structure. This broad applicability underscores why the best tunnel dryer systems are valued across diverse fields.

Selecting a Reliable Tunnel Dryer Manufacturer

Choosing the right tunnel dryer manufacturer is a critical step in ensuring the success of your drying operations. A reputable manufacturer will not only provide high-quality equipment but also offer comprehensive support, from design and installation to maintenance and upgrades. When evaluating potential suppliers, consider their experience in your industry, as this indicates their ability to address unique challenges. For example, a manufacturer specializing in food-grade tunnel dryers will have expertise in hygiene standards and material compatibility, which might differ from those focused on industrial minerals.

Another factor to assess is the manufacturer's commitment to innovation and quality control. The best tunnel dryer manufacturers invest in research and development to incorporate the latest technologies, such as energy-efficient components and smart controls. They should also have robust testing procedures to ensure that each unit meets performance specifications before delivery. Additionally, look for manufacturers that offer customization options, as this allows you to tailor the dryer to your specific production requirements. Partnering with a continuous dryer OEM that provides end-to-end services can streamline the process, reducing downtime and ensuring a smooth integration into your facility. By conducting thorough due diligence, including reviewing client testimonials and visiting production facilities, you can identify a tunnel dryer manufacturer that aligns with your business goals and delivers long-term value.

Understanding Continuous Dryer OEM Services

A continuous dryer OEM (Original Equipment Manufacturer) specializes in designing and producing drying systems that operate without interruption, catering to the needs of various industries. Unlike standard manufacturers, an OEM often provides bespoke solutions, engineering equipment from the ground up to match client specifications. This includes everything from initial concept development and prototyping to full-scale production and after-sales support. For businesses seeking a tunnel dryer, working with a continuous dryer OEM ensures that the system is optimized for their specific applications, whether it involves unique material handling requirements or integration with existing machinery.

The advantages of engaging a continuous dryer OEM include access to expert knowledge and cutting-edge technology. These manufacturers typically have in-house engineering teams that can address complex challenges, such as optimizing heat transfer or reducing energy consumption. They also stay abreast of industry trends, incorporating advancements like automation and IoT connectivity to enhance functionality. Moreover, an OEM relationship often leads to better cost efficiency, as customized designs can eliminate unnecessary features and focus on what matters most for your operation. When selecting a continuous dryer OEM, verify their certifications and track record to ensure they adhere to international standards. This collaboration can result in a tunnel dryer that not only meets but exceeds expectations, driving productivity and innovation in your processes.

What Makes the Best Tunnel Dryer?

Identifying the best tunnel dryer involves evaluating several key criteria, including performance, durability, and total cost of ownership. First and foremost, the dryer should deliver consistent and efficient drying results, with minimal variation in product quality. This requires precise control over temperature, humidity, and airflow, which can be achieved through advanced control systems and sensors. Energy efficiency is another critical factor; the best tunnel dryer models incorporate features like heat recovery and insulated designs to reduce power consumption and operational costs. Additionally, ease of maintenance and accessibility for cleaning are important, as they impact downtime and hygiene, especially in regulated industries like food and pharmaceuticals.

The reputation of the tunnel dryer manufacturer also plays a significant role in determining quality. Manufacturers with a history of innovation and customer satisfaction are more likely to produce reliable equipment. It's advisable to seek out models that offer scalability, allowing for future expansions or modifications as your business grows. User reviews and case studies can provide insights into real-world performance, helping you gauge whether a particular tunnel dryer is suited to your needs. Furthermore, the best tunnel dryer should come with robust warranty and support services, ensuring that any issues are promptly addressed. By considering these aspects, you can invest in a system that not only enhances your current operations but also adapts to future challenges, securing a solid return on investment.

In summary, tunnel dryers are a vital component in modern industrial processes, offering continuous, efficient, and reliable drying solutions. From understanding the fundamentals of how an industrial tunnel dryer operates to selecting the right tunnel dryer manufacturer and leveraging the expertise of a continuous dryer OEM, businesses can significantly improve their productivity and product quality. The best tunnel dryer combines advanced technology with practical design, catering to diverse applications while minimizing environmental impact. As industries continue to evolve, investing in a high-quality tunnel dryer will remain a strategic move for those aiming to stay competitive. By applying the insights shared in this article, you can navigate the market with confidence and choose a system that meets your specific needs.

Frequently Asked Questions

Q1: What is the primary advantage of using an industrial tunnel dryer over other drying methods?

A1: The primary advantage of an industrial tunnel dryer is its continuous operation, which allows for high-volume processing with consistent quality and reduced downtime. Unlike batch dryers, it enables non-stop production, making it ideal for industries with large-scale outputs. Additionally, the controlled zoning within the tunnel ensures uniform drying, minimizing product damage and energy waste.

Q2: How do I choose a reliable tunnel dryer manufacturer?

A2: To choose a reliable tunnel dryer manufacturer, consider their industry experience, customer reviews, and ability to provide customized solutions. Look for manufacturers with a proven track record, certifications like ISO standards, and comprehensive support services. It's also beneficial to visit their facilities or request case studies to assess the quality and performance of their equipment in real-world scenarios.

Q3: What should I expect when working with a continuous dryer OEM?

A3: When working with a continuous dryer OEM, you can expect a collaborative approach that includes custom design, engineering, and manufacturing tailored to your specific needs. They will typically conduct a thorough analysis of your requirements, provide prototypes or simulations, and ensure seamless integration into your production line. Ongoing support and maintenance are often part of the package, ensuring long-term reliability.

Q4: What features define the best tunnel dryer on the market?

A4: The best tunnel dryer is characterized by energy efficiency, precise control systems, durability, and adaptability to various materials. Key features often include advanced automation, heat recovery mechanisms, easy maintenance access, and scalability. It should also come from a reputable manufacturer with strong customer support and a warranty, ensuring it meets industry standards and your operational goals.

Q5: Can a tunnel dryer be used for sensitive products like food or pharmaceuticals?

A5: Yes, a tunnel dryer can be effectively used for sensitive products like food or pharmaceuticals, provided it is designed with appropriate controls for temperature, humidity, and hygiene. Many industrial tunnel dryer models are built to comply with strict regulatory standards, such as FDA or GMP, and can include features like stainless steel construction and HEPA filters to prevent contamination and ensure product safety.

Q6: How does a tunnel dryer contribute to sustainability in industrial processes?

A6: A tunnel dryer contributes to sustainability by optimizing energy use through features like heat recovery and efficient airflow design. This reduces overall carbon footprint and operational costs. Additionally, its continuous operation minimizes waste by ensuring consistent drying, which lowers the rate of product rejection. Many modern tunnel dryers also incorporate renewable energy sources or materials, aligning with eco-friendly initiatives.

Q7: What maintenance is required for a tunnel dryer to ensure long-term performance?

A7: Regular maintenance for a tunnel dryer includes cleaning the interior and conveyor system, inspecting and replacing worn parts like belts or heaters, and calibrating sensors and controls. It's important to follow the manufacturer's guidelines and schedule periodic professional inspections to prevent breakdowns. Proper maintenance not only extends the equipment's lifespan but also maintains efficiency and safety standards.