In today's fast-paced world, preserving food efficiently and healthily is a priority for many households and businesses. A food drying machine stands out as a versatile tool that extends the shelf life of fruits, vegetables, herbs, and meats by removing moisture, thereby inhibiting microbial growth. This method of food preservation is not only cost-effective but also retains nutrients better than many alternatives. As demand for sustainable and convenient food storage solutions grows, understanding the intricacies of food dehydration equipment becomes crucial. This article delves into the various aspects of these machines, from types and benefits to selection criteria and pricing, providing a comprehensive resource for anyone considering investing in this technology. Whether you're a home user or a commercial entity, the insights here will help you make an informed decision.

What is a Food Drying Machine?

A food drying machine is an appliance designed to remove water content from food items through controlled airflow and temperature. By reducing moisture levels, it prevents spoilage and preserves the food's nutritional value, flavor, and texture. These devices range from simple countertop models for home use to large-scale industrial systems. The core principle involves circulating warm air around the food, which accelerates evaporation without cooking the items. This process is part of a broader category known as food dehydration equipment, which includes dehydrators, drying ovens, and solar dryers. Unlike traditional methods like sun-drying, a food drying machine offers consistency, speed, and hygiene, making it a popular choice in both domestic and commercial settings. For instance, many people use it to make dried snacks like apple chips or jerky, while food processing companies rely on it for bulk production. The evolution of this technology has led to more energy-efficient and user-friendly models, emphasizing the importance of choosing the right equipment based on individual needs.

Types of Food Dehydration Equipment

When exploring food dehydration equipment, it's essential to recognize the diversity available in the market. Broadly, these can be categorized into household dehydrators, commercial dryers, and industrial-scale systems. Household models are typically compact, with stackable trays or shelves, and are ideal for small batches. They often feature adjustable temperature settings to handle different food types, from delicate herbs to hearty meats. On the other hand, commercial-grade food drying machine units are larger, with enhanced airflow systems and higher capacity, suitable for restaurants or small farms. Industrial systems, such as tunnel dryers or fluidized bed dryers, are used in large-scale food processing plants and can handle tons of produce daily. Another variant includes solar-powered dehydrators, which leverage renewable energy for eco-friendly drying. Each type of food dehydration equipment offers unique advantages; for example, household models prioritize ease of use, while industrial versions focus on throughput and automation. Understanding these categories helps in selecting the right food drying solutions that align with your volume requirements and sustainability goals.

Benefits of Food Drying Solutions

Adopting food drying solutions brings numerous advantages, from economic savings to health benefits. Firstly, drying food reduces waste by preserving surplus produce, which is especially valuable in regions with seasonal harvests. A food drying machine enables users to create long-lasting snacks without additives or preservatives, promoting a healthier lifestyle. Nutritionally, dried foods retain most vitamins and minerals, unlike canning or freezing, which can lead to nutrient loss. Moreover, food drying solutions are cost-effective in the long run; by extending food shelf life, they lower grocery bills and minimize frequent purchases. For businesses, investing in efficient food dehydration equipment can streamline operations, reduce storage costs, and open revenue streams through dried product sales. Environmentally, these solutions often consume less energy compared to other preservation methods, especially with modern, energy-efficient models. Additionally, dried foods are lightweight and easy to transport, making them ideal for camping, hiking, or emergency supplies. Overall, integrating a food drying machine into your routine supports sustainability, health, and convenience.

Choosing a Reliable Food Dryer Manufacturer

Selecting a reputable food dryer manufacturer is critical to ensure product quality, durability, and after-sales support. A reliable manufacturer typically offers a range of food dehydration equipment tailored to different needs, from home kitchens to industrial facilities. When evaluating a food dryer manufacturer, consider factors like industry experience, certifications (e.g., ISO standards), and customer reviews. Established manufacturers often provide warranties, technical assistance, and spare parts, which are essential for long-term use. For instance, companies that specialize in food drying solutions might offer innovative features like digital controls, timers, and energy-saving modes. It's also wise to assess their customization options; some manufacturers allow modifications to meet specific requirements, which ties into the availability of custom food drying equipment. By choosing a trusted food dryer manufacturer, you can avoid common pitfalls such as mechanical failures or inefficient performance, ensuring your investment pays off over time. Researching and comparing multiple manufacturers can help you find a partner that aligns with your budget and operational needs.

Innovative Food Drying Solutions for Modern Needs

The evolution of food drying solutions has introduced advanced technologies that enhance efficiency and user experience. Modern food drying machine models often incorporate smart features like programmable settings, humidity sensors, and connectivity options for remote monitoring. These innovations make the drying process more precise, reducing the risk of over-drying or under-drying. For example, some food dehydration equipment now uses heat pump technology, which recycles heat to cut energy consumption by up to 50% compared to conventional methods. Another trend is the integration of solar-assisted systems, which appeal to eco-conscious users. Additionally, food drying solutions have expanded to include specialized dryers for unique products like dairy powders or pet food, showcasing the versatility of this equipment. In commercial settings, automation through conveyor dryers or batch systems improves productivity and consistency. These advancements highlight how food dryer manufacturer companies are responding to market demands for sustainability and convenience. By staying updated on these innovations, consumers can select food drying solutions that not only meet their current needs but also adapt to future challenges.

Custom Food Drying Equipment for Specific Applications

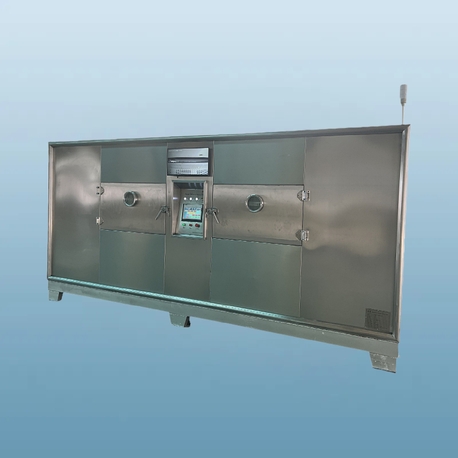

For businesses with unique requirements, custom food drying equipment offers tailored solutions that standard models cannot provide. This type of food dehydration equipment is designed to handle specific food types, volumes, or processing conditions. For instance, a food dryer manufacturer might develop a custom system for drying delicate herbs that require low temperatures and gentle airflow to preserve essential oils. Similarly, custom food drying equipment can be engineered for high-moisture foods like tomatoes or fish, incorporating features like multi-stage drying or specialized trays. The process typically involves collaboration with the manufacturer to assess needs, design prototypes, and test performance. This approach ensures that the food drying machine integrates seamlessly into existing production lines, optimizing efficiency. While custom food drying equipment may come at a higher initial cost, it often leads to better output quality and long-term savings by reducing waste and energy use. Industries such as pharmaceuticals or agriculture also benefit from customized dryers for non-food items, demonstrating the broad applicability of these solutions. When considering custom food drying equipment, it's important to work with experienced manufacturers who can deliver reliable and scalable systems.

Factors Influencing Food Drying Machine Price

Understanding the food drying machine price is essential for budgeting and making a cost-effective purchase. The price of a food drying machine varies widely based on factors like capacity, features, and type. Basic household models can start as low as $50, while high-end commercial or custom food drying equipment may cost thousands of dollars. Key determinants of food drying machine price include the unit's size and throughput; larger capacities generally command higher prices. Additionally, advanced features such as digital controls, programmable timers, and energy-efficient technologies can increase the cost. The reputation of the food dryer manufacturer also plays a role; well-known brands often charge a premium for quality and reliability. Other factors include materials used in construction—stainless steel models are more durable but pricier—and any certifications for safety and efficiency. When evaluating food drying machine price, consider long-term operating costs, such as energy consumption and maintenance, which can impact the overall investment. For businesses, it's wise to compare quotes from multiple suppliers and assess the return on investment through reduced waste and increased productivity. By analyzing these elements, you can find a food drying machine that offers the best value for your needs.

In summary, a food drying machine is a valuable asset for anyone looking to preserve food efficiently and healthily. From understanding the various types of food dehydration equipment to selecting a trustworthy food dryer manufacturer, this overview highlights key considerations for potential buyers. The benefits of food drying solutions extend beyond mere preservation, encompassing economic, health, and environmental advantages. For specialized applications, custom food drying equipment provides tailored options that enhance performance. When it comes to food drying machine price, factors like capacity, features, and manufacturer reputation all influence the cost, making it crucial to balance upfront expenses with long-term gains. As technology advances, these machines continue to evolve, offering smarter and more sustainable food drying solutions. By leveraging this knowledge, you can make an informed choice that meets your specific requirements, whether for home use or commercial operations.

Frequently Asked Questions

Q1: What is the average lifespan of a food drying machine?

A1: The average lifespan of a food drying machine depends on usage, maintenance, and quality. Household models typically last 5-10 years with proper care, while commercial food dehydration equipment can endure 10-20 years due to robust construction. Regular cleaning and following the manufacturer's guidelines can extend its life.

Q2: How does a food drying machine compare to freeze-drying?

A2: A food drying machine uses warm air to remove moisture, resulting in chewy textures and retained nutrients, whereas freeze-drying involves freezing and vacuuming to preserve food, yielding crispier results and longer shelf life. Freeze-drying is often more expensive and complex, making food drying solutions more accessible for everyday use.

Q3: Can I dry different types of food simultaneously in one machine?

A3: Yes, many food drying machine models allow drying different foods at once, but it's recommended to group items with similar drying times and temperatures to avoid cross-flavoring or uneven results. For optimal outcomes, consult the food dryer manufacturer instructions on tray arrangement and settings.

Q4: What maintenance is required for food dehydration equipment?

A4: Maintenance for food dehydration equipment includes regular cleaning of trays and interior surfaces to prevent mold, checking for airflow blockages, and inspecting electrical components. Most food drying solutions come with user manuals detailing specific care routines to ensure longevity and efficiency.

Q5: Are there energy-efficient options available to reduce operating costs?

A5: Absolutely, many modern food drying machine units incorporate energy-saving features like insulated chambers, heat pump technology, and programmable shut-offs. When comparing food drying machine price, consider models with high energy ratings to lower long-term electricity bills, and look for food dryer manufacturer offerings that emphasize sustainability.