In the world of large-scale manufacturing, time is just as valuable as the raw materials themselves. When a facility handles thousands of units per hour, traditional batch drying methods often become a significant bottleneck. This is where the tunnel dryer becomes an essential asset. By allowing products to move continuously through a heated chamber, businesses can maintain a seamless flow from production to packaging without interruption.

Choosing the right thermal processing equipment requires a deep understanding of how heat interacts with different materials. Whether it is removing moisture from food products or curing inks on industrial textiles, the efficiency of the process dictates the profit margin. Manufacturers like Nasan have spent years perfecting these continuous systems to ensure they meet the rigorous demands of modern international trade.

Understanding the Core Mechanics of a Tunnel Dryer

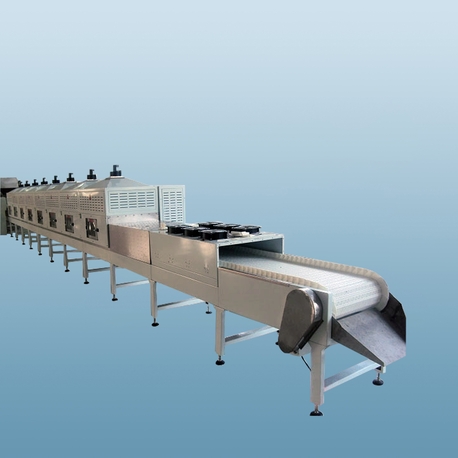

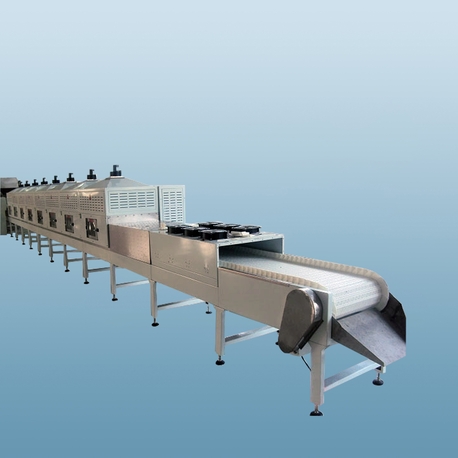

A tunnel dryer functions as a long, insulated enclosure equipped with a conveyor system. Unlike static ovens, these machines are designed for movement. As the product travels from the inlet to the outlet, it is exposed to controlled thermal conditions that are precisely calibrated for that specific material.

The heat source can vary depending on the application. Some systems utilize steam coils, while others rely on gas burners or electric infrared elements. The key to its success is not just the heat, but the airflow. High-velocity fans circulate air around the product to strip away the boundary layer of moisture, significantly accelerating the evaporation process compared to still-air environments.

The Operational Workflow of Continuous Drying

The process begins at the loading zone. Here, raw or processed materials are spread evenly across a conveyor belt. It is crucial that the thickness of the layer is consistent. If the material is bunched up, the center will remain damp while the edges might overcook or become brittle.

As the belt moves into the first zone of the tunnel dryer, the material undergoes a pre-heating phase. This stage raises the internal temperature of the product to the evaporation point without causing surface damage. Most high-end systems allow operators to set different temperatures for different sections of the tunnel, providing a customized drying curve.

In the middle sections, the "constant-rate" drying occurs. This is where the bulk of the moisture is removed. Finally, as the product nears the exit, it enters a cooling or stabilization zone. This prevents thermal shock and ensures the product is at a safe temperature for immediate handling or bagging. Companies often look to Nasan for systems that integrate these zones into a single, automated PLC-controlled unit.

Key Application Areas Across Global Industries

The food industry is perhaps the most visible user of this technology. From breakfast cereals and pasta to dried pet treats, the ability to process tons of product daily is mandatory. A continuous system ensures that every piece of food receives the exact same thermal treatment, which is vital for meeting food safety regulations and flavor consistency.

In the textile and printing sectors, the tunnel dryer plays a different role. Here, it is often used to cure coatings or dry screen-printed designs on garments. Because these machines can be dozens of feet long, they provide enough "dwell time" for the chemical reactions to complete even when the belt is moving at high speeds.

The construction and chemical industries also rely on these systems. For instance, molded fiber products, ceramic components, and granulated chemicals require slow, steady moisture removal to prevent cracking. The controlled environment of a tunnel prevents the rapid surface shrinking that often occurs in less sophisticated drying setups.

Solving Efficiency Challenges in the Factory

One of the primary concerns for any factory manager is energy consumption. Large drying tunnels can be expensive to run if they are not insulated properly. Modern solutions involve high-density mineral wool insulation and heat recovery systems. These systems capture the hot air that would normally be vented out and recirculate it back into the heating chamber.

Another common problem is "uneven drying" across the width of the belt. If the air is only blowing from one side, the products in the middle might stay wet. To solve this, advanced engineering designs use "cross-flow" or "down-draft" air distribution. This ensures that the air reaches every square inch of the conveyor belt with equal pressure and temperature.

Nasan has addressed these common pain points by developing modular designs. This allows a business to start with a standard length and add more heating zones as their production needs increase. It is a cost-effective way to scale a business without replacing the entire machinery line.

Choosing the Right Belt Material for Your Process

The conveyor belt is the heart of the machine, and its material must match the environment. For food-grade applications, stainless steel mesh is often the standard. It is easy to sanitize and allows air to flow through the bottom of the product, which is essential for uniform drying.

For chemical or high-heat processes, Teflon-coated fiberglass belts are frequently used. These are non-stick and can withstand extreme temperatures without degrading. Choosing the wrong belt can lead to "product sticking" or even mechanical failure if the belt stretches or warps under the heat of the tunnel dryer.

Automation and the Move Toward Smart Manufacturing

The integration of the Internet of Things (IoT) has transformed how these machines are managed. Operators no longer need to stand by the machine with a stopwatch and a thermometer. Modern sensors can detect the moisture level of the product in real-time and automatically adjust the belt speed or temperature to compensate.

If a batch of raw material arrives with a higher-than-normal moisture content, the system detects this at the entry point and slows the conveyor down. This level of automation reduces the risk of human error and ensures that no "wet" product ever reaches the packaging stage. This smart technology is a hallmark of the premium service provided by brands like Nasan.

Maintenance and Safety Protocols

Like any heavy industrial equipment, a tunnel dryer requires a consistent maintenance schedule to perform at its peak. The most common maintenance task is cleaning the air filters and heat exchangers. Dust and debris can build up quickly, especially in food or textile plants, which restricts airflow and creates a fire hazard.

Lubricating the drive motors and checking the tension of the conveyor belt is also essential. A slipping belt can lead to inconsistent drying times and mechanical wear. Most manufacturers recommend a monthly inspection of the heating elements or burners to ensure they are firing efficiently and not wasting fuel.

Safety is equally important. Large tunnels must be equipped with emergency stop buttons at both ends and "explosion relief" panels if they are processing volatile chemicals or fine powders. Ensuring that your staff is trained in these safety protocols is just as important as the quality of the machine itself.

Long-Term ROI of Continuous Drying Systems

While the initial investment in a high-capacity system can be significant, the return on investment (ROI) is usually realized through labor savings and increased throughput. A single continuous line can often replace four or five batch ovens, freeing up valuable floor space and reducing the number of operators required to manage the process.

Furthermore, the consistency provided by a tunnel dryer reduces product waste. In a batch system, if one oven fails, the entire batch is lost. In a continuous system, parameters are adjusted on the fly, ensuring a much higher yield of "grade-A" product. When you factor in the energy savings from modern heat-recovery technology, the machine often pays for itself within a few years of operation.

As the global manufacturing sector continues to evolve, the need for speed, precision, and sustainability will only grow. Investing in a reliable tunnel dryer is a strategic move for any company looking to dominate their market. With the engineering support of established names like Nasan, businesses can transition from small-scale production to global distribution with confidence and efficiency.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a batch oven and a tunnel dryer?

A1: A batch oven processes a fixed amount of material at one time and must be loaded and unloaded manually. A tunnel dryer uses a conveyor belt to move products continuously through the heat, allowing for a constant flow of production and higher efficiency.

Q2: How do I know what length of tunnel my factory needs?

A2: The length depends on your "dwell time"—the amount of time the product needs to stay under heat—and your required belt speed. If a product needs 10 minutes to dry and you want to move 2 meters of belt per minute, you would need at least a 20-meter heating zone.

Q3: Can these machines handle fragile items?

A3: Yes. For fragile items, we use solid belts or fine-mesh belts to prevent indentation. The airflow can also be adjusted so that it doesn't "blow" lightweight products off the conveyor.

Q4: What heat sources are the most cost-effective for a tunnel dryer?

A4: This depends on local energy prices. Generally, natural gas is the most cost-effective for very large systems, while electricity is preferred for smaller, high-precision units or facilities that have access to cheap renewable energy.

Q5: Is it possible to dry different products on the same line?

A5: Absolutely. Most modern systems feature digital controllers where you can save "recipes." When you switch products, you simply select the new profile, and the machine automatically adjusts the temperature and belt speed to the pre-set levels.

Q6: How does moisture exit the machine?

A6: As the tunnel dryer heats the product, the moisture turns into vapor. An exhaust system, often located at the top of the tunnel, pulls this moist air out of the chamber. Many systems now include heat exchangers to keep the heat inside while letting the moisture escape.