In today's competitive industrial landscape, optimizing processes for efficiency and cost-effectiveness is paramount. One key piece of equipment that plays a vital role in various sectors is the industrial dehydrator. This machine is designed to remove moisture from materials on a large scale, ensuring preservation, quality, and extended shelf life. Whether in food processing, pharmaceuticals, or chemical manufacturing, an industrial dehydration machine is indispensable for maintaining product integrity and reducing waste. As businesses seek reliable solutions, understanding the nuances of industrial drying solutions, selecting a reputable industrial dehydrator manufacturer, and evaluating the industrial dryer price become critical steps in making informed decisions. This article delves into the essential aspects of industrial dehydrators, providing insights into their functionality, benefits, and factors to consider when investing in one. By the end, you'll have a comprehensive view of how these machines can transform your operations and what to look for in the market.

What Is an Industrial Dehydrator and How Does It Work?

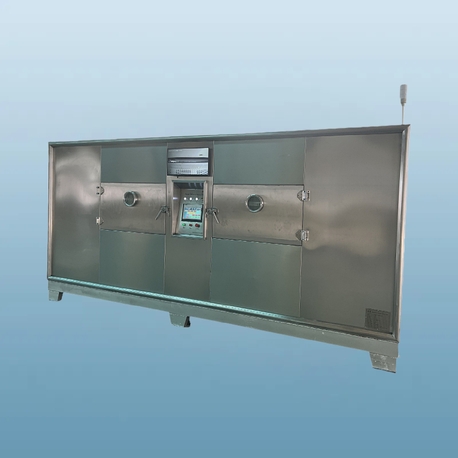

An industrial dehydrator is a heavy-duty machine used to extract water or other liquids from materials through controlled heating and airflow. Unlike smaller, domestic dehydrators, these units are built for high-capacity operations, handling everything from fruits and vegetables to chemicals and textiles. The core principle involves circulating warm air evenly across the material, which accelerates evaporation without compromising the product's structural or nutritional properties. This process is central to industrial drying solutions, as it ensures consistent results across large batches. Modern industrial dehydration machines often incorporate advanced technologies like programmable logic controllers (PLCs) and energy-efficient heat pumps, allowing for precise temperature and humidity control. By leveraging these features, businesses can achieve optimal dehydration rates, reduce energy consumption, and maintain compliance with industry standards. Essentially, an industrial dehydrator serves as a backbone for many production lines, enabling scalability and reliability in demanding environments.

Key Applications of Industrial Dehydration Machines

Industrial dehydration machines are versatile tools employed across a wide range of industries. In the food sector, they are used to dry fruits, vegetables, herbs, and meats, creating shelf-stable products that retain flavor and nutrients. This not only reduces food waste but also opens up opportunities for value-added goods. Similarly, in the pharmaceutical industry, these machines dry medicinal herbs, enzymes, and other compounds, ensuring stability and potency for medications. The chemical and manufacturing sectors rely on industrial dehydrators to process materials like plastics, ceramics, and minerals, where moisture control is critical for product quality and safety. Additionally, wastewater treatment plants use industrial drying solutions to reduce sludge volume, making disposal more environmentally friendly and cost-effective. The adaptability of these machines means that nearly any industry dealing with moisture-sensitive materials can benefit from their use. By investing in a quality industrial dehydrator, companies can enhance their production capabilities, meet regulatory requirements, and explore new market opportunities.

Choosing the Right Industrial Dehydrator Manufacturer

Selecting a reliable industrial dehydrator manufacturer is a crucial step in ensuring long-term performance and support. A reputable manufacturer will offer machines that are built to last, with robust construction and compliance with international safety standards. When evaluating potential suppliers, consider their experience in your specific industry, as this can impact the customization and effectiveness of the equipment. Look for manufacturers that provide comprehensive services, including installation, training, and after-sales support. This is particularly important for complex industrial drying solutions that may require integration into existing production lines. Additionally, check for certifications and customer testimonials to gauge reliability. A trusted industrial dehydrator manufacturer will often have a portfolio of successful projects and be transparent about their manufacturing processes. By partnering with such a company, you can avoid common pitfalls like frequent breakdowns or inefficient operation, ultimately protecting your investment and maximizing ROI.

Comprehensive Industrial Drying Solutions for Modern Needs

Industrial drying solutions encompass a broad spectrum of technologies and approaches tailored to different operational requirements. Beyond standard dehydrators, these solutions may include fluidized bed dryers, spray dryers, or freeze dryers, each suited for specific materials and output goals. For instance, an industrial dehydration machine might be ideal for solid foods, while spray dryers are better for liquids like milk or coffee extracts. The key is to assess factors such as material characteristics, production volume, and energy efficiency when selecting a solution. Many providers offer integrated systems that combine dehydration with other processes, such as cooling or packaging, to streamline operations. As sustainability becomes a priority, innovative industrial drying solutions are emerging that use renewable energy sources or recycle heat, reducing environmental impact. By understanding the full range of options available, businesses can implement a system that not only meets current needs but also adapts to future challenges and opportunities.

Factors Influencing Industrial Dryer Price

The industrial dryer price can vary significantly based on several factors, making it essential to conduct a thorough cost-benefit analysis. First, the machine's capacity and size play a major role; larger units designed for high-throughput operations will generally command a higher price. Second, the technology and features incorporated, such as automation, energy recovery systems, or specialized controls, can increase costs but may lead to long-term savings through improved efficiency. Third, the choice of materials and build quality—for example, stainless steel versus mild steel—affects both durability and price. Additionally, customization to meet specific industry standards or spatial constraints can add to the expense. When considering the industrial dryer price, it's important to look beyond the initial purchase and factor in operational costs, maintenance, and potential downtime. Consulting with an experienced industrial dehydrator manufacturer can help you navigate these variables and find a machine that offers the best value for your budget. Remember, a higher upfront cost might be justified by lower energy consumption, reduced waste, and enhanced productivity over time.

Benefits of Implementing an Industrial Dehydrator

Integrating an industrial dehydrator into your operations offers numerous advantages that extend beyond mere moisture removal. One of the primary benefits is improved product quality, as controlled dehydration preserves essential properties like color, texture, and nutritional content. This is especially valuable in food and pharmaceutical applications where consumer satisfaction and safety are paramount. Another key advantage is cost reduction; by removing moisture, companies can lower shipping weights, minimize storage space, and decrease spoilage rates. Moreover, industrial dehydration machines contribute to sustainability efforts by reducing waste and energy usage when equipped with modern efficiency features. From a business perspective, these machines enable scalability, allowing firms to handle increased demand without compromising on consistency. Overall, an industrial dehydrator is a strategic investment that supports operational resilience, compliance with industry regulations, and competitive edge in the market.

Common Questions About Industrial Dehydrators

Q1: What is the typical lifespan of an industrial dehydration machine?

A1: The lifespan of an industrial dehydration machine varies based on usage, maintenance, and build quality, but with proper care, it can last 10 to 20 years. Regular servicing and adherence to manufacturer guidelines are key to maximizing longevity.

Q2: How do I choose the right industrial dehydrator manufacturer?

A2: When selecting an industrial dehydrator manufacturer, consider their industry experience, customer reviews, certifications, and after-sales support. It's also wise to request case studies or references to verify their track record in providing reliable industrial drying solutions.

Q3: What factors most affect the industrial dryer price?

A3: The industrial dryer price is influenced by capacity, technology level, material construction, customization needs, and energy efficiency. Higher-end models with advanced features may cost more upfront but often lead to lower operational expenses.

Q4: Can an industrial dehydrator handle different types of materials?

A4: Yes, most industrial dehydrators are designed to process a variety of materials, from foods and chemicals to textiles, by adjusting temperature and airflow settings. However, it's important to consult with the manufacturer to ensure compatibility with specific products.

Q5: Are there energy-efficient options in industrial drying solutions?

A5: Absolutely. Many modern industrial drying solutions incorporate heat pumps, solar-assisted systems, or energy recovery mechanisms to reduce electricity consumption and environmental impact, making them a sustainable choice for businesses.

In conclusion, the industrial dehydrator is a cornerstone of efficient production across multiple industries, offering tangible benefits in quality, cost savings, and sustainability. By carefully evaluating factors such as the industrial dehydrator manufacturer, industrial drying solutions, and industrial dryer price, businesses can make informed decisions that align with their goals. As technology advances, these machines will continue to evolve, providing even greater value and innovation. If you're considering an upgrade or new installation, take the time to research and partner with experts to ensure optimal outcomes for your operations.