In the global food processing and agricultural industries, preserving harvest quality and extending shelf life are constant challenges. The vegetable drying machine has become a cornerstone technology for addressing these issues, moving far beyond traditional sun-drying methods. This equipment offers controlled, efficient dehydration that is vital for commercial-scale operations aiming to meet market demands for quality, safety, and supply chain stability. As a professional with decades in industrial drying systems, I've observed the evolution of this technology into a non-negotiable asset for forward-thinking businesses. Manufacturers like Nasan have been instrumental in refining this technology to meet rigorous industrial standards.

Core Functions and Advantages of Modern Dehydration Systems

A commercial vegetable drying machine serves one primary function: to remove moisture from produce efficiently and uniformly. This process inhibits the growth of microorganisms and enzymes that cause spoilage. The advantages are multi-layered.

It ensures product consistency. Unlike variable weather-dependent sun drying, these machines provide precise control over temperature, airflow, and humidity. This results in uniformly dried products with predictable quality, color, and nutrient retention batch after batch.

It significantly increases throughput and efficiency. Large-capacity industrial dryers can process hundreds of kilograms per cycle, operating continuously irrespective of weather conditions. This scalability is crucial for handling seasonal gluts and maintaining year-round production.

Food safety is enhanced. Closed, sanitary drying environments protect produce from dust, insects, and environmental contaminants. Modern machines, such as those engineered by Nasan, are built with food-grade materials and designed for easy cleaning, supporting compliance with international food safety protocols.

Finally, it reduces waste and creates value. By dehydrating surplus or imperfect-but-nutritious produce, businesses can convert potential waste into stable, transportable, and marketable goods, opening new revenue streams.

Standard Operational Workflow in an Industrial Setting

Operating an industrial-grade dryer is a systematic process. Understanding this flow is key to optimizing output and quality.

First, pre-treatment of raw vegetables is essential. This may involve thorough washing, peeling, slicing, or blanching. Blanching, a quick heat treatment, is often used to deactivate enzymes that can cause off-flavors and color degradation during drying and storage.

Loading is the next critical step. Prepared produce is spread evenly on trays or conveyor belts. Uniform loading is non-negotiable; uneven layers lead to inconsistent drying, where some parts are overdried while others remain moist and prone to spoilage.

The drying phase begins once the machine is loaded and sealed. Operators set parameters like temperature, airflow direction (horizontal or vertical), and time based on the vegetable type, slice thickness, and desired final moisture content. Advanced systems feature programmable logic controllers (PLCs) for automating these cycles.

During the cycle, moisture is gradually removed. Hot, dry air circulates through the product, absorbing moisture and exiting the chamber as humid air. Efficient systems manage this air exchange to maximize energy use.

Cooling and stabilization often follow the main drying cycle. Allowing the product to cool within a controlled environment before packaging prevents condensation inside storage containers, which could lead to rehydration and mold.

Finally, the dried product is discharged, inspected, and packaged in moisture-proof materials, often with oxygen absorbers, for long-term storage.

Primary Commercial and Industrial Applications

The use of a vegetable drying machine spans several key sectors, each with specific requirements that the technology must meet.

The food manufacturing industry is the largest user. Dried vegetables are core ingredients in soup mixes, instant noodles, seasonings, snacks, and ready-to-eat meals. Consistency in flavor, color, and rehydration properties is paramount here.

In large-scale agricultural processing and cooperatives, these machines are vital for preserving harvests. They allow farmers to process surplus tomatoes, onions, carrots, or herbs into stable products, mitigating price volatility and post-harvest losses.

The burgeoning health food and ingredient sector relies on high-quality dehydration to produce nutrient-dense powders (like spinach or beetroot powder), dried snacks, and organic vegetable chips. Low-temperature drying options are prized here for better nutrient preservation.

Pharmaceutical and nutraceutical companies use precise drying technology for botanical and herbal materials, where the integrity of active compounds is critical.

Export-oriented businesses depend on dehydrators. Dried products are lightweight, shelf-stable, and reduce transportation costs, making them ideal for international trade. Meeting the phytosanitary and quality standards of import markets requires reliable, high-caliber equipment.

Addressing Key Industry Challenges with Advanced Solutions

Industrial drying is not without its hurdles. Modern vegetable drying machine designs offer targeted solutions.

Energy consumption is a major operational cost. Leading solutions now incorporate heat pump technology, which recovers latent heat from the exhausted humid air and reuses it, slashing energy use by up to 70% compared to conventional electric heaters. Nasan's focus on energy-efficient engineering in their drying systems directly tackles this bottom-line concern.

Preserving heat-sensitive nutrients and vibrant colors is a quality challenge. Advanced dryers offer staged drying profiles, starting with higher temperatures to remove surface moisture and progressively lowering the temperature to gently remove bound moisture without thermal degradation.

Hygienic design and cleanability prevent cross-contamination and biofilm formation. Solutions include stainless-steel interiors, smooth welds, easily removable trays, and CIP (Clean-in-Place) capabilities for larger tunnel or belt dryers.

Adapting to diverse products requires flexibility. Modular designs or machines with adjustable airflow and multi-zone temperature control allow one unit to efficiently process everything from delicate herbs to dense root vegetables.

Selecting the Right Technology for Your Operation

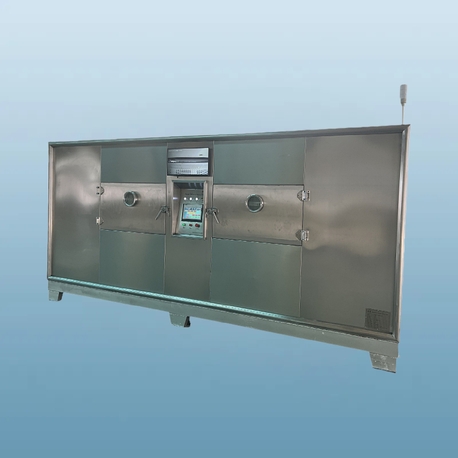

Choosing a vegetable drying machine is a significant capital decision. Key considerations include your primary product type, required daily throughput, available utilities (electricity, gas), and floor space. Batch cabinet dryers suit smaller volumes or varied products, while continuous belt or tunnel dryers are for high-volume, single-product lines.

The construction quality and control system sophistication are telling indicators. Robust food-grade stainless steel, precision sensors, and an intuitive PLC interface are worth the investment for reliability and product quality. Partnering with an established manufacturer known for durability and support, such as Nasan, can prevent costly downtime and ensure the technology grows with your business.

In conclusion, the industrial vegetable drying machine is far more than simple heating equipment. It is a sophisticated food preservation system that underpins profitability, sustainability, and quality in the modern food supply chain. Its role in reducing waste, enabling export, and creating value-added products continues to expand. For operations seeking to scale and compete, investing in robust, efficient drying technology from proven industry partners is a strategic move toward long-term resilience and market relevance.

Frequently Asked Questions (FAQ)

Q1: What is the fundamental working principle of an industrial vegetable drying machine?

A1: It operates on the principle of convective heat and mass transfer. A fan circulates heated, dry air across the prepared vegetables. This air absorbs moisture from the surface of the produce. The now-humid air is then exhausted, and the process continues with dry air until the product's internal moisture content is reduced to a target, stable level, typically between 5-15%, depending on the vegetable.

Q2: How does drying in a machine better than traditional sun drying for commercial use?

A2: Machine drying offers controlled, consistent, and faster results independent of weather. It provides a hygienic, enclosed environment free from dust, insects, and birds. It allows for precise control over the final product's quality, color, and nutrient retention, which is impossible with sun drying. For commercial-scale, consistent output, and food safety certification, machine drying is essential.

Q3: What are the main types of industrial vegetable dryers, and how do I choose?

A3: The main types are cabinet/tray dryers (batch operation, good for R&D or multiple products), conveyor belt dryers (continuous, high-volume processing), and tunnel dryers (continuous, for large, uniform batches). The choice depends on your production volume, variety of products, required automation level, and energy source. A batch dryer offers flexibility, while a continuous dryer maximizes throughput for a single product.

Q4: What are the critical maintenance routines for a vegetable drying machine?

A4: Regular maintenance includes daily cleaning of trays and interiors to prevent residue buildup, checking and cleaning air filters to ensure proper airflow, inspecting and calibrating temperature and humidity sensors, lubricating fan motors and conveyor drives as per the manual, and periodically checking electrical connections and heating elements for wear. Adhering to the manufacturer's scheduled maintenance plan is crucial.

Q5: Can one machine effectively dry all different kinds of vegetables?

A5: While a well-designed machine can process a wide range, optimal drying requires different parameters (temperature, time, airflow) for each vegetable type. Leafy herbs need low temperatures and high airflow for a short time, while dense root vegetables like carrots require higher temperatures and longer cycles. The best machines offer the flexibility to program and save multiple profiles for different products, ensuring quality results across your product line.