For commercial mushroom growers and processors, the harvest is only half the battle. The true challenge lies in preservation. Mushrooms are highly perishable, with over 90% water content. Drying is the most effective method to extend shelf life, concentrate flavor, and unlock global market access. However, not all drying is equal. Using the wrong technique can destroy texture, diminish nutritional value, and erase the delicate umami flavor that defines quality. An industrial mushroom dryer is not a luxury; it’s the core piece of equipment that determines your final product's value and your operation's profitability. Over the years, I've seen too many businesses compromise on drying technology, only to face inconsistent results and customer complaints. Investing in a purpose-built system, like those engineered by specialists such as Nasan, is the definitive solution.

Why Mushrooms Present a Unique Drying Challenge

Mushrooms are not like herbs or root vegetables. Their cellular structure and high moisture content demand specific drying conditions. Getting it wrong leads to common, costly problems.

If the temperature is too high at the start, a hard shell forms on the exterior. This traps moisture inside, a condition called case hardening. The interior then steams, leading to a tough, rubbery, or even spoiled final product.

Conversely, drying too slowly at low temperatures can allow enzymatic and microbial activity to continue. This results in discoloration—turning dark and unappealing—and a significant loss of the prized aromatic compounds.

The goal is uniform, controlled dehydration that removes moisture efficiently while preserving the mushroom's shape, natural color, and complex flavor profile. This precision is what separates a basic food dehydrator from a true industrial mushroom dryer.

Core Functions of a Commercial-Grade Dryer

A professional system goes beyond simply applying heat. It manages the entire microenvironment around the product.

The primary function is precise temperature and humidity control. Modern dryers feature staged programming. An initial phase uses lower temperatures with high airflow to remove surface moisture without shock. Subsequent stages gradually increase heat to draw out internal water, all while managing relative humidity inside the chamber to optimize the drying rate.

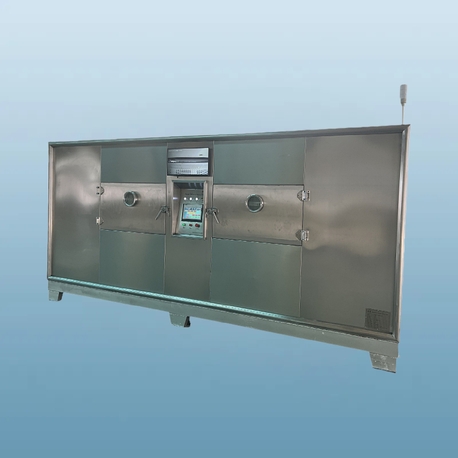

Uniform air distribution is non-negotiable. Every tray, every corner of the drying chamber must receive consistent airflow. Hot or cold spots create batch inconsistency, meaning some mushrooms are perfectly dry while others are under-processed. Superior designs use carefully engineered plenum systems and axial fans to ensure even distribution.

Hygienic construction is mandatory for food safety. Interiors should be made of polished, food-grade stainless steel, with smooth welds and minimal crevices. This prevents contamination, allows for easy cleaning, and meets stringent international food processing standards.

Energy efficiency directly impacts your bottom line. Advanced systems employ heat pump technology or intelligent heat recovery methods. These innovations recycle thermal energy from the exhaust air, dramatically reducing operating costs compared to conventional electric or gas-fired dryers.

Standardized Operational Workflow for Optimal Results

Consistent output requires a disciplined process. Here is the standard workflow used by successful commercial operations.

First, meticulous sorting and preparation are crucial. Mushrooms must be cleaned of substrate, sorted by size, and sliced uniformly. Consistent slice thickness, typically between 4-8mm, is the single most important factor for even drying. Slicing increases surface area, speeding up the process significantly.

Loading the trays demands attention. Slices should be spread in a single, even layer without overlapping. Overcrowding blocks airflow, creating pockets of humid air that slow drying and promote inconsistency. Proper loading is a simple but vital step.

The drying cycle is then initiated using a pre-set program. A typical multi-stage program might run: 2-3 hours at 35-40°C with high fan speed, followed by 6-8 hours at 45-50°C, and a final finishing stage at 50-55°C. The exact parameters depend on the mushroom species (shiitake, oyster, morel, etc.) and slice thickness.

During drying, operators monitor the product's moisture content, aiming for a final level between 8-12%. This "safe" moisture level ensures stability for long-term storage without over-drying and wasting energy.

Finally, a conditioning or tempering period is often beneficial. After drying, allowing the mushrooms to rest in a sealed container for 24 hours lets residual moisture equilibrate throughout all pieces. They are then immediately packaged in moisture-barrier bags.

Primary Commercial Applications and Markets

The output from an industrial mushroom dryer feeds into diverse and lucrative markets.

The largest segment is the food manufacturing industry. Dried mushroom slices and powders are essential ingredients in soups, sauces, stock cubes, seasoning blends, instant noodles, and ready meals. These buyers demand consistent color, flavor strength, and rehydration properties batch after batch.

The gourmet and speciality food sector seeks whole dried specimens like morels, porcini, or high-grade shiitake. Presentation, intense aroma, and flavor retention are paramount here, commanding premium prices. This requires the gentlest drying protocols.

The nutraceutical and supplement industry utilizes mushrooms like Reishi, Chaga, and Lion's Mane. They dry these for extraction or to make powders for capsules. Their focus is on preserving the bioactive compounds (beta-glucans, triterpenes), which are sensitive to excessive heat.

For the grower and primary processor, drying is a risk management tool. It allows them to preserve large harvests, stabilize prices by selling throughout the year, and convert less-than-perfect fresh mushrooms (slightly blemished or off-size) into a valuable, storable product.

Export is almost entirely dependent on drying. Removing over 90% of the water drastically reduces weight and volume, slashing shipping costs. It also creates a shelf-stable product that can travel without cold chains, opening up international trade opportunities.

Critical Selection Factors for Your Business

Choosing the right system is a major capital decision. Focus on these five key factors.

First, assess your throughput and capacity. Calculate your average wet weight per day you need to process. Industrial dryers are rated by wet weight capacity per batch (for cabinet dryers) or per hour (for continuous belt dryers). Always factor in future growth.

Second, prioritize control system sophistication. A simple thermostat is inadequate. Look for a PLC (Programmable Logic Controller) touchscreen that allows you to create, save, and repeat multi-stage drying profiles. This reproducibility is the foundation of consistent quality.

Third, examine energy efficiency and operating costs. Request specific power consumption data (kWh per kg of water removed). Heat pump dryers, while a higher initial investment, can reduce energy costs by 50-70% compared to traditional electric models. This saving quickly justifies the premium. Nasan has integrated advanced heat recovery in many of their models, demonstrating a commitment to lower lifetime operating costs.

Fourth, insist on hygienic and robust construction. Inspect the interior finish, the quality of the seals, and the accessibility for cleaning. The machine must be built to withstand a damp, demanding production environment for years.

Fifth, consider vendor support and expertise. The manufacturer should understand food processing, not just metal fabrication. They should offer guidance on drying profiles for different species and provide reliable after-sales service. A partner like Nasan, with focused experience, becomes an asset to your operation.

In summary, an industrial mushroom dryer is a precision instrument for value creation. It transforms a fragile, seasonal agricultural product into a stable, versatile, and globally marketable commodity. The choice of equipment directly influences your product quality, operational costs, and business scalability. By focusing on controlled airflow, staged drying, and energy-smart technology, you protect your investment and build a reputation for excellence. For operations where quality cannot be left to chance, partnering with a dedicated industrial drying specialist is the most logical step forward.

Frequently Asked Questions (FAQ)

Q1: What is the ideal final moisture content for commercially dried mushrooms?

A1: The target is typically between 8% and 12% moisture content (wet basis). At this level, water activity is sufficiently low to inhibit microbial growth and enzymatic reactions, ensuring shelf stability for over a year when packaged correctly. Different markets or further processing steps may have specific requirements.

Q2: Should mushrooms be blanched before drying in an industrial machine?

A2: Generally, no. Blanching (brief boiling) is used for many vegetables but is not standard for most culinary mushrooms. It can lead to significant texture and nutrient loss. The industry standard is to clean, slice, and load directly into the dryer. The controlled, multi-stage drying process itself stabilizes the product.

Q3: How do I calculate the required dryer capacity for my farm?

A3: A basic calculation is: (Daily wet harvest weight in kg) x (Drying cycle time in hours / 24 hours). For example, if you harvest 500kg of fresh mushrooms daily and your target drying cycle is 12 hours, you need a system capable of holding at least 250kg of wet product per batch (500 x 12/24 = 250). Always add a 20-30% buffer for peak harvest.

Q4: Can the same dryer process different mushroom species effectively?

A4: Yes, but with different programs. Delicate oysters require lower temperatures than dense portobello stems. A high-quality industrial dryer allows you to save custom programs—each with unique temperature stages, fan speeds, and times—for each species or slice thickness you process. This versatility is key.

Q5: What is the main advantage of a heat pump mushroom dryer versus a traditional electric one?

A5: The primary advantage is dramatically lower energy consumption and operating cost. A heat pump dryer works by recycling heat from the exhaust air, making it far more efficient. It also often provides better dehumidification control at lower temperatures, which is excellent for the initial, critical drying phase where heat sensitivity is highest.