In industrial processing, removing moisture efficiently while preserving product integrity is a constant challenge. Traditional hot-air drying methods often struggle with uneven results, long cycle times, and high energy costs, especially for heat-sensitive materials. This has driven the adoption of advanced volumetric heating technologies. Among these, the industrial microwave dryer represents a significant leap forward. By using electromagnetic energy to directly excite water molecules within a product, it achieves rapid, uniform drying from the inside out. This technology is moving beyond lab-scale curiosity into serious consideration for food, pharmaceutical, and chemical production lines. For companies evaluating this shift, understanding the operational and economic realities is key. Manufacturers with robust engineering backgrounds, such as Nasan, have been instrumental in developing industrial-grade systems that withstand continuous use.

The Core Technology: Beyond the Kitchen Appliance

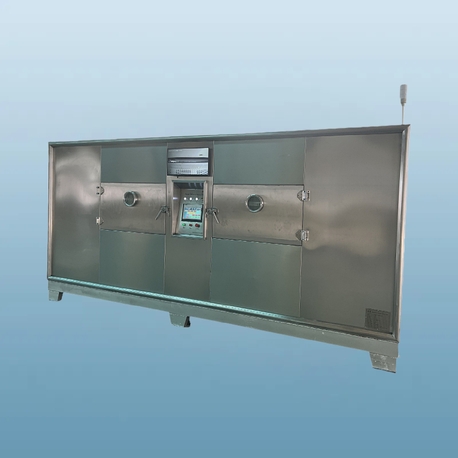

It’s crucial to distinguish an industrial microwave dryer from a domestic microwave oven. The former is a precision-engineered thermal processing system.

The unit generates microwaves, typically at 915 MHz or 2450 MHz, via a magnetron. These waves are directed into an enclosed chamber or a conveyor-tunnel. The product, transported on belts or trays, is exposed to this controlled field.

Water molecules within the product are polar. They rapidly oscillate, aligning themselves with the alternating electromagnetic field. This molecular friction generates heat directly inside the material, not from the outside in. This core mechanism is what defines the technology's advantages and limitations.

Key Operational Advantages for Industrial Users

The shift to this technology is driven by tangible benefits that impact both product quality and the bottom line.

Speed is the most cited advantage. Drying times can be reduced by 50-80% compared to conventional methods. Since heat is generated internally, the thermal gradient is reversed. The interior dries as fast as, or faster than, the surface.

This leads to superior product quality. For many foods and botanicals, case-hardening—a hard, dried shell trapping interior moisture—is avoided. Color, nutrient content, and rehydration properties are often better preserved.

Energy efficiency can be markedly higher. Energy is transferred directly to the water needing evaporation, not to heating air, the chamber walls, or the non-aqueous parts of the product. This targeted approach reduces total energy consumption.

Process control is also enhanced. Modern systems integrate infrared sensors and moisture analyzers for real-time feedback, allowing automatic power adjustment to maintain optimal drying conditions throughout the cycle.

Primary Industrial and Commercial Use Cases

This technology is not a universal solution, but it excels in specific, high-value applications.

In the food industry, it is used for finishing snacks like crackers or pasta to achieve perfect crispness, drying fruits and vegetables with improved color retention, and pre-cooking or tempering products. The rapid drying of herbs and spices is another strong fit, as it better locks in volatile aromas.

The pharmaceutical and chemical industries use it for precise drying of granules, powders, and catalyst materials where uniform moisture content is critical for downstream processing or stability.

In advanced materials manufacturing, it aids in drying ceramic castings or specialized textiles where controlled, internal heating prevents stress cracking.

Integrating a Microwave Dryer into Your Production Line

Implementation requires careful planning. It is often most effective as part of a hybrid system.

A common configuration uses a conventional hot-air dryer for the initial "constant-rate" drying phase, where free surface moisture is removed. The material then enters the microwave dryer for the "falling-rate" period, where internal moisture migration becomes the limiting factor. This hybrid approach maximizes efficiency and product quality.

Material handling systems must be designed for even exposure. Product must be spread uniformly on the conveyor, and the system often includes mode stirrers or rotating turntables to ensure microwave field uniformity.

Critical Considerations and Challenges

While powerful, the technology has specific constraints that must be addressed.

Initial capital expenditure is higher than for traditional dryers. A compelling return on investment depends on factors like product value, throughput, and energy savings.

Product composition matters greatly. Uneven distribution of moisture or salts can lead to localized overheating, known as "hot spotting." This requires careful process development and control system tuning.

Not all materials are suitable. Products that are essentially fat-based or completely non-polar will not absorb microwave energy effectively. Conversely, very thin materials may not absorb enough energy to be practical.

Maintenance demands are different. Magnetrons have a finite lifespan and are a replaceable component. The system must be properly shielded and maintained for operator safety.

The Future and Technological Evolution

The technology continues to mature. Modern industrial units focus on improved magnetron efficiency and longevity. Sophisticated control systems now use multiple sensors and algorithms to dynamically adjust power in different zones of the dryer.

Research is ongoing into pulsed microwave drying and more precise frequency control to target specific moisture states. The goal is ever-greater precision and energy efficiency, making the technology viable for a broader range of materials.

The industrial microwave dryer is a powerful tool for specific drying challenges where speed, quality, and targeted energy use are paramount. It is a technology of precision, not brute force. Its successful adoption hinges on a clear understanding of the product's physical properties and a willingness to invest in proper process engineering.

For operations where it fits, the benefits in product superiority, throughput, and operational cost can be substantial. It represents a move towards more intelligent, responsive manufacturing. As with any significant process change, partnering with an experienced equipment provider who understands both the technology and industrial-scale production realities—a space where firms like Nasan have built their expertise—is essential for a successful implementation.

Frequently Asked Questions (FAQ)

Q1: Is microwave drying safe for food products? Does it affect nutrients?

A1: Yes, when properly controlled, it is a safe and approved method. In many cases, nutrient retention is superior to hot-air drying due to the significantly shorter exposure to heat, which helps preserve heat-sensitive vitamins and antioxidants.

Q2: How does the energy consumption compare to a traditional hot-air dryer?

A2: Energy efficiency is generally higher because energy is directly converted to heat within the water molecules, minimizing losses to the environment. However, the overall comparison depends on the specific application, product, and whether the system is used in a standalone or hybrid configuration. Total energy savings of 20-40% are commonly reported.

Q3: Can a microwave dryer handle all types of materials?

A3: No. It is highly effective for materials with high water content. It is less effective or unsuitable for drying non-polar substances like oils or fats, or for very thin materials where penetration depth is not utilized. A thorough product test is always recommended.

Q4: What is the main maintenance concern with an industrial system?

A4: The primary consumable component is the magnetron, the device that generates microwaves. Its lifespan varies with usage but is a known replacement item. Regular inspection of seals, waveguides, and safety interlocks is also critical for safe, efficient operation.

Q5: Why is a hybrid drying system often recommended?

A5: A hybrid system combines the strengths of different technologies. Conventional dryers efficiently remove surface moisture at lower cost. The microwave dryer then efficiently tackles the harder-to-remove internal moisture. This combination often provides the best balance of capital cost, operational efficiency, and final product quality.