Selecting the proper industrial herb dryer is a critical decision for businesses in the food, pharmaceutical, cosmetic, and agricultural sectors. It directly impacts product quality, operational efficiency, and profit margins. Unlike simple food dehydrators, industrial-scale equipment must deliver consistent, uniform results while handling large volumes of delicate botanical material. This guide explores the key factors, technologies, and considerations to help you choose a system that aligns with your production goals and quality standards.

Whether you are processing basil, mint, medicinal cannabis, chamomile, or any other valuable herb, the drying phase is where product integrity and market value are solidified. An efficient herb dryer preserves vital active compounds, color, and aroma while preventing mold and microbial growth.

How an Industrial Herb Dryer Works

The core principle of any herb dryer is the controlled removal of moisture. However, industrial systems achieve this with precision engineering. They manage temperature, airflow, humidity, and time within an enclosed chamber or conveyor system.

The process begins with prepared herbs loaded onto trays or a continuous belt. Heated, dehumidified air is then circulated uniformly around the material. The system carefully evaporates moisture without “cooking” the herbs. Advanced dryers feature programmable logic controllers (PLC) to replicate perfect drying cycles batch after batch, ensuring standardized output crucial for compliance and consumer trust.

Key Technologies in Commercial Herb Drying

Not all dryers are created equal. The technology you choose depends on your raw material and desired finished product.

Tray dryers are a common batch-style solution, ideal for smaller batches or R&D. Herbs are spread on stacked trays in a closed cabinet, with forced air circulation. While effective, loading and unloading can be labor-intensive.

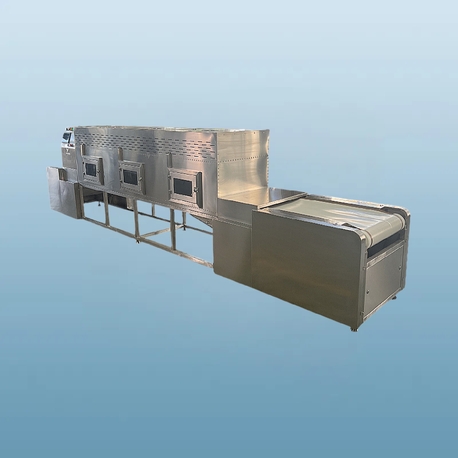

Continuous belt dryers offer higher throughput for large-scale operations. Herbs move on a mesh belt through different temperature zones, allowing for a steady input and output of product. This is excellent for high-volume processing of a single herb type.

Heat pump drying technology is gaining popularity for its energy efficiency. It recycles heat within the system, operating at lower temperatures. This gentle method is superb for preserving terpenes and volatile oils in sensitive herbs, leading to a superior final product.

Choosing Your Herb Dryer: A Decision Framework

Your choice should be guided by several concrete business factors. First, consider your throughput requirements. Calculate your current and projected volume of fresh herbs per day to determine the necessary capacity.

Second, define your quality parameters. Are you drying delicate culinary herbs where color and aroma are paramount, or robust medicinal herbs where preserving specific cannabinoids or active ingredients is the goal? This will dictate the acceptable temperature range.

Third, evaluate your facility constraints. Assess available floor space, utility connections (gas, electric, steam), and ventilation. Finally, establish a budget, considering both capital expenditure (CAPEX) and long-term operating costs (OPEX) like energy consumption and maintenance. Brands like Nasan have developed a range of dryers to meet these varied operational scales and quality demands, from efficient batch units to fully automated continuous lines.

Essential Features for Optimal Drying Results

Look for systems with precise control systems. Digital interfaces for setting and monitoring temperature, airflow, and time are non-negotiable for repeatability. Uniform air distribution is another critical feature; hotspots or dead zones will ruin a batch.

Hygienic design with easy-clean surfaces, such as stainless steel interiors, is vital for food and pharmaceutical applications. For batch dryers, a well-sealed door with good insulation improves efficiency. Data logging capabilities are increasingly important, providing records for quality audits and process optimization.

Energy Efficiency and Total Cost of Ownership

The purchase price is just the beginning. An energy-efficient herb dryer can save thousands in utility costs annually. Compare the specific energy consumption (kWh per kg of water removed) of different models. Heat pump dryers, for instance, often have a higher upfront cost but significantly lower running costs.

Factor in maintenance needs. Systems with robust components and accessible service points reduce downtime. A reliable supplier will provide a clear picture of expected maintenance schedules and spare part availability. Considering the total cost of ownership over 5-10 years often makes a more efficient machine the smarter financial choice.

Installation, Maintenance, and Safety

Professional installation is recommended to ensure optimal performance and safety. This includes proper electrical or gas hookup and integration with your facility’s ventilation. Routine maintenance typically involves cleaning filters, inspecting fans and heating elements, and calibrating sensors.

Safety is paramount. Industrial dryers involve heat and electricity. Choose equipment with comprehensive safety certifications, automatic over-temperature shutoffs, and proper guarding. Operators should be thoroughly trained on safe loading, unloading, and emergency procedures.

Partnering with a Reputable Manufacturer

Your herb dryer is a long-term investment. Partnering with an experienced manufacturer provides peace of mind. Look for a company with a proven track record in your industry. They should offer strong technical support, clear documentation, and readily available spare parts.

A good partner will help you conduct tests with your specific herb to validate the drying cycle before purchase. They can also guide you on scalability for future growth. Established engineering firms like Nasan bring decades of drying expertise to the table, offering tailored solutions and support throughout the machine's lifecycle, ensuring your operation runs smoothly from day one.

Investing in the right industrial herb dryer is a strategic move that safeguards product quality, boosts efficiency, and protects your bottom line. By thoroughly understanding your production needs, the available technologies, and the importance of features like precise control and energy efficiency, you can make an informed decision. A reliable, well-designed drying system is not just a piece of machinery; it’s a cornerstone of a successful and scalable herb processing business. Proper due diligence in selecting your herb dryer, supported by expert partners, will yield dividends in product excellence and operational reliability for years to come.

Frequently Asked Questions (FAQ)

Q1: What is the average price range for an industrial herb dryer?

A1: Prices vary widely based on capacity, technology, and automation. Small batch tray dryers may start around $10,000-$15,000, while large, fully automated continuous belt dryers with heat pump technology can exceed $200,000. It’s best to get quotes based on your specific output requirements (e.g., kg of fresh herb per hour).

Q2: How long does it take to dry herbs in an industrial dryer compared to air drying?

A2: Industrial drying is significantly faster. Air drying can take 5-10 days with high risk of contamination. An industrial herb dryer can reduce moisture content to the target level (often 8-12%) in a matter of hours, typically between 4 to 24 hours depending on the herb type, initial moisture, and dryer technology.

Q3: Can the same dryer be used for different types of herbs?

A3: Yes, a versatile herb dryer with programmable settings can process multiple herbs. However, the drying cycle (temperature, time, airflow) must be adjusted and optimized for each specific plant material to preserve its unique qualities. It’s crucial to clean the system thoroughly between batches to prevent cross-contamination of aromas or residues.

Q4: What are the most common mistakes when operating a commercial herb dryer?

A4: Common mistakes include overloading the trays or belt, which restricts airflow; using too high a temperature, which “cooks” and degrades the herbs; not pre-cleaning herbs of stems or foreign material; and neglecting regular maintenance of filters and fans, which reduces efficiency and uniformity.

Q5: How do I ensure my dried herbs meet regulatory standards for my industry?

A5: Compliance starts with choosing a dryer designed for your industry (e.g., food-grade stainless steel, cleanable surfaces). Precise, documentable control over the drying process is key. A dryer with data logging capabilities provides essential records for audits, proving consistent time-temperature profiles and ensuring each batch is processed identically to meet set standards.