In the world of commercial herb production, whether for culinary, medicinal, or aromatic purposes, preserving the essential oils, color, and potency of the plant material is paramount. This is where the unsung hero of the processing line comes into play: the industrial herb dryer. Unlike traditional sun-drying or small-scale dehydrators, a commercial herb dryer is engineered to deliver consistent, high-volume results while meticulously controlling the environment to protect delicate active compounds. For businesses looking to scale up, understanding the function, operation, and benefits of this crucial equipment is a game-changer. Brands like Nasan have been at the forefront, developing dryers that meet the rigorous demands of modern herb processing.

What is a Commercial Herb Dryer and Why is it Essential?

A commercial herb dryer is a specialized piece of industrial machinery designed to remove moisture from large batches of herbs efficiently and uniformly. The core challenge in drying herbs is that they are often delicate; too much heat can destroy volatile oils (which carry flavor and aroma), while insufficient airflow can lead to mold and spoilage.

The essential role of a herb drying machine is threefold:

Preservation: By reducing the moisture content to a safe level (typically below 10%), it prevents the growth of microorganisms, thereby extending shelf life significantly.

Quality Retention: Advanced dryers use controlled temperatures and airflow to lock in the natural color, active constituents, and aromatic profile of the herbs. This is critical for market value, as faded or bland herbs are commercially undesirable.

Efficiency and Scalability: Manual or primitive drying methods are labor-intensive, weather-dependent, and unsuitable for large volumes. An industrial herb dryer can process hundreds of kilograms per batch, turning what was a bottleneck into a smooth, continuous operation.

Key Applications: Where are Herb Dryers Used?

The use of a commercial herb dryer extends far beyond a single industry. Any business that deals with bulk plant material can benefit.

Pharmaceutical and Nutraceutical Industries: For drying medicinal herbs like echinacea, mint, chamomile, and St. John's Wort, where the potency of active ingredients is non-negotiable.

Culinary and Spice Industry: To process basil, oregano, parsley, rosemary, and other culinary herbs without degrading their flavor.

Tea Production: Ensuring that tea leaves (like green tea, peppermint, or hibiscus) retain their color, aroma, and beneficial properties.

Aromatherapy and Essential Oils: Some plants are dried before the distillation process for essential oils, and their quality directly impacts the final oil yield and quality.

The Operational Workflow of an Industrial Herb Dryer

Operating a herb drying machine is a systematic process designed for maximum efficiency and quality control.

Pre-treatment and Loading: Freshly harvested herbs are typically sorted and may be roughly pre-dried to remove surface moisture. They are then spread evenly on trays, which are loaded into the drying chamber. Uniform loading is crucial for consistent airflow and drying.

Parameter Setting: The operator sets the key parameters on the control panel. This includes temperature (usually kept low, between 30°C and 45°C / 86°F and 113°F), humidity levels, and airflow velocity. Modern units from manufacturers like Nasan often feature programmable logic controllers (PLCs) for precise and repeatable cycles.

The Drying Cycle: The machine closes, and the cycle begins. Heated, dehumidified air is circulated evenly throughout the chamber. The herb dryer slowly and gently extracts moisture without "cooking" the plant material. The process can take several hours to a day, depending on the herb's initial moisture content and density.

Monitoring and Completion: Throughout the cycle, sensors monitor the internal conditions. In some advanced systems, the process stops automatically once the target moisture content is achieved. The trays are then unloaded, and the dried herbs are ready for further processing like cutting, grinding, and packaging.

Choosing the Right Herb Dryer: A Solution-Oriented Approach

Selecting the appropriate herb dryer is not a one-size-fits-all decision. It requires a solutions-based approach tailored to specific needs.

For Heat-Sensitive Herbs: A heat pump herb dryer is ideal. It uses a refrigerant cycle to dehumidify and gently heat the air, operating at lower temperatures and offering superior energy efficiency. This is a core technology in many Nasan dryers, perfect for preserving delicate compounds.

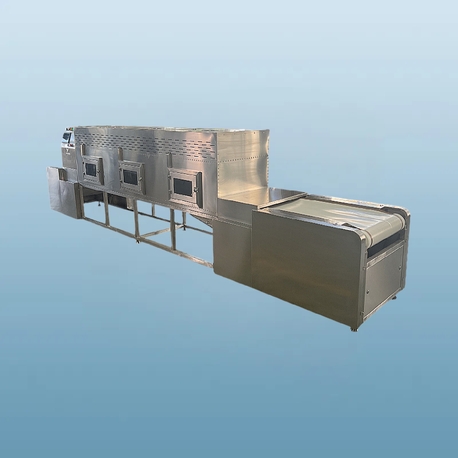

For High-Volume, Continuous Processing: A conveyor belt herb drying machine is the solution. Herbs are fed onto a belt that moves through different temperature zones, allowing for non-stop, high-throughput drying.

For Small to Medium Batches with High Variety: A cabinet-style herb dryer with multiple trays is perfect. It offers the flexibility to dry different herbs in separate batches without cross-contamination.

When evaluating a supplier, consider their expertise in your specific sector. A company like Nasan, with experience in phytopharmaceutical processing, will understand the nuanced requirements better than a general industrial dryer manufacturer.

The Tangible Benefits of Investing in a Professional Herb Dryer

The return on investment for a high-quality herb dryer is clear and multi-faceted.

Uncompromised Product Quality: The primary benefit. You get a consistently dried product that looks, smells, and performs as intended.

Increased Throughput and Profitability: Dramatically reduce drying times compared to traditional methods, allowing you to process more material and meet market demands.

Reduced Labor and Operational Costs: Automation reduces the need for constant manual turning and monitoring.

Year-Round, Weather-Independent Operation: No more worries about rain, humidity, or insufficient sunlight disrupting your production schedule.

Hygiene and Compliance: A closed, controlled system minimizes the risk of contamination from dust, insects, or pests, helping you meet strict food and pharmaceutical safety standards.

In the competitive landscape of commercial herb production, the method of dehydration can be the defining factor between a premium product and a mediocre one. An industrial herb dryer is not merely a piece of equipment; it is a critical investment in quality, efficiency, and business growth. By enabling precise control over the drying environment, it ensures that the very essence of the herb is captured and preserved. As technology advances, leaders in the field, including Nasan, continue to refine these machines, offering smarter, more energy-efficient solutions for producers worldwide. Upgrading to a professional herb drying machine is a strategic move that pays dividends in product excellence and operational supremacy.

Frequently Asked Questions (FAQ) About Commercial Herb Dryers

Q1: What is the ideal temperature for drying herbs in a commercial dryer?

A1: The ideal temperature range for most delicate herbs is between 30°C and 45°C (86°F - 113°F). Higher temperatures can degrade volatile oils, chlorophyll, and active compounds, leading to a loss of aroma, color, and potency. The exact setting depends on the specific herb and its moisture content.

Q2: How long does it take to dry a full batch of herbs commercially?

A2: Drying time varies significantly based on the herb type, its initial moisture content, the loading density of the machine, and the specific dryer technology. It can range from as little as 4-6 hours for thin-leafed herbs to 18-24 hours for denser roots or stalks. A modern herb dryer with precise controls offers more consistent and predictable cycle times.

Q3: Can the same herb dryer be used for different types of herbs?

A3: Yes, a commercial herb dryer is designed for versatility. However, it is crucial to clean the machine thoroughly between batches of different herbs to prevent cross-contamination of flavors and aromas. Using trays and racks that are easy to sanitize is a key feature to look for.

Q4: What is the difference between a heat pump herb dryer and a traditional hot air dryer?

A4: A traditional hot air dryer uses electric or gas heaters to raise the air temperature, which can be less energy-efficient and harder to control at low temperatures. A heat pump herb dryer works like a reverse air conditioner, using a refrigerant to dehumidify and gently heat the air. It is far more energy-efficient and excels at maintaining the low temperatures required for sensitive herbs.

Q5: How do I determine the capacity of herb dryer I need for my business?

A5: Calculate your average daily or weekly harvest weight of fresh herbs. Remember that herbs can lose up to 80-90% of their weight during drying. A manufacturer's sales engineer, like those at Nasan, can help you analyze your production data and recommend a herb drying machine with the appropriate chamber volume and tray capacity to match your output goals.