In today's rapidly evolving industrial landscape, the quest for sustainable and efficient waste management solutions has never been more critical. Among the innovative technologies gaining traction, microwave pyrolysis stands out as a revolutionary method that leverages microwave energy to decompose materials in an oxygen-free environment, producing valuable by-products like bio-oil, syngas, and char. This process not only addresses environmental concerns but also enhances resource recovery, making it a cornerstone for industries aiming to reduce their carbon footprint and operational costs. As global regulations tighten and the demand for green technologies rises, understanding the intricacies of microwave pyrolysis becomes essential for businesses seeking to stay competitive. This article delves into the core aspects of this technology, from the design of industrial microwave pyrolysis systems to practical guidance on sourcing equipment, all while exploring its application in industrial drying processes. By the end, you'll have a comprehensive view of how microwave pyrolysis is reshaping industries, backed by insights into equipment manufacturers and purchasing considerations.

What is Microwave Pyrolysis?

Microwave pyrolysis is a thermochemical process that uses microwave radiation to heat organic materials in the absence of oxygen, leading to their decomposition into gases, liquids, and solids. Unlike conventional pyrolysis, which relies on external heating sources, microwave pyrolysis employs electromagnetic waves that penetrate materials directly, causing molecular friction and rapid temperature rise. This results in faster reaction times, higher energy efficiency, and better control over the end products. The process is particularly effective for treating a wide range of feedstocks, including biomass, plastics, and industrial sludge, transforming them into useful resources such as biofuels, chemicals, and activated carbon. The uniqueness of microwave pyrolysis lies in its selective heating capability, which minimizes energy loss and reduces the risk of unwanted by-products. As industries worldwide grapple with waste management challenges, microwave pyrolysis offers a scalable solution that aligns with circular economy principles, turning waste into wealth while mitigating environmental impacts.

The Role of Industrial Microwave Pyrolysis Systems

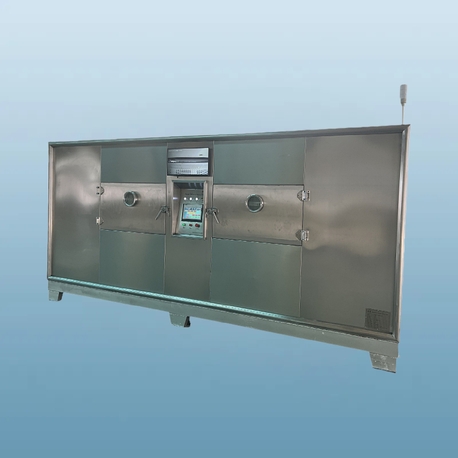

An industrial microwave pyrolysis system is a sophisticated setup designed for large-scale applications, integrating components like microwave generators, reactors, condensers, and gas treatment units. These systems are engineered to handle high volumes of waste materials efficiently, ensuring consistent output quality and operational safety. For instance, in the waste management sector, an industrial microwave pyrolysis system can process tons of municipal solid waste per day, converting it into energy-rich syngas that can power industrial facilities. The key advantage of such systems is their ability to operate continuously, with automated controls that monitor temperature, pressure, and microwave power in real-time. This not only optimizes the pyrolysis process but also reduces human intervention, lowering labor costs. Moreover, industrial microwave pyrolysis systems are often customized to suit specific feedstocks, such as agricultural residues or electronic waste, enhancing their versatility. By integrating these systems, industries can achieve significant reductions in landfill use and greenhouse gas emissions, while generating additional revenue streams from the sale of pyrolysis products. As technology advances, we're seeing innovations like hybrid systems that combine microwave pyrolysis with other treatment methods, further boosting efficiency and scalability.

Microwave Pyrolysis Equipment Manufacturers

When it comes to sourcing reliable technology, microwave pyrolysis equipment manufacturers play a pivotal role in driving adoption across industries. These manufacturers range from global corporations to specialized firms, each offering unique systems tailored to different applications. For example, companies like Carbolite Gero and C-Therm Technologies are known for their advanced microwave pyrolysis solutions that emphasize energy efficiency and compliance with environmental standards. When evaluating microwave pyrolysis equipment manufacturers, it's crucial to consider factors such as technical support, warranty terms, and the ability to provide customized designs. Many manufacturers also offer pilot testing services, allowing businesses to validate the technology before full-scale implementation. In recent years, the market has seen a surge in manufacturers from Asia and Europe, driven by increasing demand for sustainable waste treatment options. These players often focus on cost-effective models without compromising on safety features, such as explosion-proof reactors and emission control systems. Additionally, reputable manufacturers invest in research and development to incorporate IoT and AI into their equipment, enabling predictive maintenance and remote monitoring. By partnering with experienced microwave pyrolysis equipment manufacturers, industries can ensure seamless integration of this technology into their operations, maximizing return on investment and minimizing downtime.

How to Buy a Microwave Pyven

Purchasing a microwave pyrolysis oven requires careful planning to match the equipment with your specific industrial needs. The first step is to assess your feedstock type, volume, and desired output products, as these factors will influence the oven's size and specifications. For instance, if you're dealing with wet biomass, you might need a system with integrated drying capabilities. When you decide to buy microwave pyrolysis oven, it's advisable to request quotes from multiple suppliers and compare their offerings based on efficiency ratings, energy consumption, and after-sales service. Many manufacturers provide online catalogs or virtual demonstrations to help buyers make informed decisions. Additionally, consider the total cost of ownership, including installation, maintenance, and potential upgrades. Financing options, such as leasing or pay-per-use models, are becoming more common, making it easier for small to medium enterprises to adopt this technology. Before finalizing a purchase, check for certifications like CE or ISO, which indicate compliance with international safety and quality standards. It's also beneficial to read case studies or customer reviews to gauge real-world performance. By taking a systematic approach to buy microwave pyrolysis oven, you can invest in a solution that not only meets your operational requirements but also supports long-term sustainability goals.

How Does Microwave Pyrolysis Work for Industrial Drying?

Understanding how does microwave pyrolysis work for industrial drying involves examining the synergy between microwave energy and material dehydration. In industrial settings, drying is a critical step that often consumes significant energy, but microwave pyrolysis revolutionizes this by combining drying and pyrolysis into a single, efficient process. When microwaves are applied to moist materials, they excite water molecules, causing rapid evaporation without the need for external heat sources. This is particularly effective for industrial drying because it reduces processing time and energy usage by up to 50% compared to conventional methods like hot air drying. For example, in the food industry, how does microwave pyrolysis work for industrial drying? It can preserve nutrients while removing moisture from agricultural products, leading to higher-quality outputs. Similarly, in waste treatment, microwave pyrolysis pre-dries sludge before pyrolysis, enhancing the overall efficiency by minimizing the energy required for thermal decomposition. The process relies on controlled microwave penetration, which ensures uniform drying and prevents overheating. This not only improves product consistency but also extends equipment lifespan. As industries seek to optimize their drying operations, the integration of microwave pyrolysis offers a dual benefit: it prepares materials for further processing while recovering value from waste streams. This makes it an attractive option for sectors like pharmaceuticals, textiles, and chemicals, where precise moisture control is essential.

Advantages of Implementing Microwave Pyrolysis in Industry

The adoption of microwave pyrolysis in industrial processes brings numerous benefits, including enhanced energy efficiency, reduced environmental impact, and economic gains. One of the primary advantages is the lower energy consumption due to direct microwave heating, which translates to cost savings and a smaller carbon footprint. Moreover, microwave pyrolysis systems are highly scalable, allowing businesses to start with pilot units and expand as needed. The technology also supports waste valorization, turning non-recyclable materials into marketable products like biochar or renewable energy. From an operational perspective, microwave pyrolysis requires less space than traditional incineration or landfilling, making it suitable for urban industrial zones. Safety is another key benefit, as the closed-system design minimizes exposure to hazardous emissions. In terms of applications, industries ranging from agriculture to manufacturing have reported improved process outcomes, such as higher purity in recovered materials and faster throughput. As global trends shift toward sustainability, companies that integrate microwave pyrolysis can gain a competitive edge by meeting regulatory requirements and appealing to eco-conscious consumers. Overall, the advantages underscore why this technology is becoming a cornerstone of modern industrial strategy.

Future Trends in Microwave Pyrolysis Technology

The future of microwave pyrolysis is bright, with ongoing research focusing on enhancing efficiency, scalability, and integration with other green technologies. Emerging trends include the development of smart systems equipped with sensors and AI algorithms that optimize process parameters in real-time, reducing waste and improving yield. Another area of innovation is the use of hybrid approaches, such as combining microwave pyrolysis with solar energy, to further cut carbon emissions. Additionally, advancements in reactor design are making systems more compact and affordable, broadening access to smaller enterprises. As circular economy models gain traction, we can expect increased collaboration between microwave pyrolysis equipment manufacturers and industries to create closed-loop systems where waste is continuously repurposed. Regulatory support and government incentives will likely accelerate adoption, particularly in regions prioritizing climate action. In the coming years, microwave pyrolysis could play a key role in emerging fields like carbon capture and hydrogen production, solidifying its position as a versatile and sustainable industrial solution.

Microwave pyrolysis represents a transformative approach to industrial waste management and resource recovery, offering a blend of efficiency, sustainability, and economic viability. From the design of robust industrial microwave pyrolysis systems to the strategic selection of equipment manufacturers, businesses have ample opportunities to leverage this technology. Understanding how does microwave pyrolysis work for industrial drying further highlights its versatility in optimizing energy-intensive processes. As the market evolves, those who invest in buying microwave pyrolysis ovens and integrating them into their operations will be well-positioned to thrive in a resource-constrained world. By embracing these innovations, industries can not only reduce their environmental impact but also unlock new revenue streams, paving the way for a greener future.

Frequently Asked Questions (FAQs)

Q1: What is the typical cost range for an industrial microwave pyrolysis system?

A1: The cost of an industrial microwave pyrolysis system can vary widely based on capacity and features, typically ranging from $50,000 to $500,000 or more. Factors influencing price include the system's throughput, level of automation, and customization requirements. It's best to consult multiple microwave pyrolysis equipment manufacturers for detailed quotes and consider long-term savings from energy efficiency and product recovery.

Q2: How does microwave pyrolysis compare to traditional pyrolysis methods?

A2: Microwave pyrolysis is generally faster and more energy-efficient than traditional methods because it uses direct microwave heating, which reduces heat loss and allows for better control over the process. This results in higher-quality outputs and lower operational costs, although initial investment might be higher. Additionally, microwave pyrolysis is safer due to its closed-system design, minimizing emission risks.

Q3: Can microwave pyrolysis handle different types of waste materials?

A3: Yes, microwave pyrolysis is highly versatile and can process a variety of feedstocks, including biomass, plastics, rubber, and industrial sludge. The key is to adjust the system parameters, such as microwave power and residence time, to suit the specific material properties. This flexibility makes it ideal for diverse industrial applications.

Q4: What safety measures are in place for microwave pyrolysis systems?

A4: Modern microwave pyrolysis systems incorporate multiple safety features, such as electromagnetic shielding to prevent radiation leaks, pressure and temperature sensors for real-time monitoring, and automatic shutdown mechanisms in case of anomalies. Reputable microwave pyrolysis equipment manufacturers also provide training and maintenance support to ensure safe operation.

Q5: How long does it take to see a return on investment when you buy a microwave pyrolysis oven?

A5: The return on investment for a microwave pyrolysis oven depends on factors like feedstock availability, product market prices, and operational scale. Typically, businesses can recoup costs within 2 to 5 years through savings in waste disposal fees, energy costs, and revenue from selling pyrolysis products like bio-oil or syngas. Conducting a feasibility study before purchase can help estimate this timeline accurately.

Q6: Is microwave pyrolysis suitable for small-scale industries?

A6: Absolutely, many manufacturers offer modular and compact microwave pyrolysis ovens designed for small to medium enterprises. These systems are scalable and can be tailored to lower throughputs, making them accessible for businesses with limited space or budget. Leasing options and government grants for green technologies can further facilitate adoption in smaller settings.