In today's competitive industrial landscape, the vacuum drying oven stands out as a versatile and efficient solution for moisture removal and material preservation. This technology leverages reduced pressure to lower the boiling point of water, enabling gentle drying of heat-sensitive substances without degradation. As industries evolve, the demand for specialized equipment like industrial vacuum drying ovens, systems tailored for food processing, custom designs, and reliable manufacturers has surged. This article dives deep into the world of vacuum drying ovens, exploring their applications, benefits, and key considerations for selection. Whether you're in pharmaceuticals, food production, or research, understanding these aspects can optimize your processes and drive innovation. We'll cover everything from basic principles to advanced customizations, ensuring you have a comprehensive view of how vacuum drying ovens can transform your operations.

What is a Vacuum Drying Oven and How Does It Work?

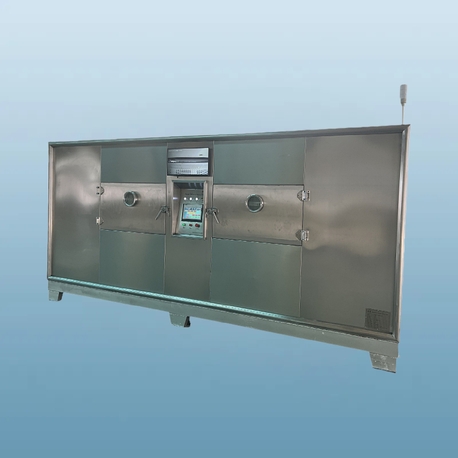

A vacuum drying oven is a specialized device that removes moisture or solvents from materials by creating a low-pressure environment. This process reduces the boiling point of liquids, allowing evaporation at lower temperatures compared to conventional drying methods. Typically, it consists of a sealed chamber, a vacuum pump, heating elements, and controls for temperature and pressure regulation. The vacuum drying oven is ideal for samples that are sensitive to heat or oxygen, as it prevents oxidation, thermal degradation, and loss of volatile compounds. Common applications include drying powders, curing resins, and preparing laboratory samples. By maintaining precise conditions, this equipment ensures consistent results, making it a staple in industries where quality and efficiency are paramount. The versatility of a vacuum drying oven extends to various sectors, from electronics to food, highlighting its adaptability and importance in modern manufacturing and research.

Industrial Vacuum Drying Oven: Enhancing Efficiency and Productivity

The industrial vacuum drying oven is designed for heavy-duty applications in sectors like chemicals, pharmaceuticals, and aerospace. These units are built to handle large volumes, high temperatures, and rigorous cycles, ensuring durability and reliability. For instance, in the chemical industry, an industrial vacuum drying oven is used to dry catalysts and polymers, reducing processing time and minimizing energy consumption. The benefits include improved product quality, as the vacuum environment prevents contamination and preserves material properties. Additionally, these ovens often feature advanced controls for automation, allowing seamless integration into production lines. When selecting an industrial vacuum drying oven, factors such as chamber size, temperature range, and vacuum level must be considered to match specific operational needs. This makes the industrial vacuum drying oven a critical asset for boosting productivity while maintaining safety standards.

Vacuum Drying for Food Processing: Ensuring Safety and Quality

Vacuum drying for food processing has revolutionized the way perishable items are preserved, extending shelf life and retaining nutritional value. This method involves placing food items in a vacuum drying oven, where low pressure and controlled heat remove moisture without cooking the product. This is particularly beneficial for fruits, vegetables, and herbs, as it preserves color, flavor, and vitamins that are often lost in traditional drying. Vacuum drying for food processing also inhibits microbial growth, enhancing food safety and reducing waste. For example, in the snack industry, it enables the production of crispy, healthy alternatives to fried foods. The process is energy-efficient and scalable, making it suitable for both small artisanal producers and large food manufacturers. By adopting vacuum drying for food processing, companies can meet consumer demands for natural, high-quality products while optimizing supply chain logistics.

Custom Vacuum Drying Oven: Tailoring Solutions to Unique Needs

A custom vacuum drying oven addresses specific requirements that standard models cannot meet, offering flexibility in design, size, and functionality. These bespoke units are ideal for niche applications, such as research institutions, where unique sample sizes or experimental conditions are involved. For instance, a custom vacuum drying oven might include specialized racks, multiple vacuum ports, or compatibility with corrosive materials. The process of developing a custom vacuum drying oven involves collaboration with manufacturers to define parameters like temperature uniformity, pressure control, and material compatibility. This ensures that the oven aligns perfectly with operational goals, whether for prototyping, batch processing, or compliance with regulatory standards. Investing in a custom vacuum drying oven can lead to long-term cost savings by improving efficiency and reducing downtime, making it a smart choice for innovative industries.

How to Choose a Reliable Vacuum Drying Oven Manufacturer

Selecting the right vacuum drying oven manufacturer is crucial for obtaining high-quality, durable equipment. A reputable vacuum drying oven manufacturer should offer a range of products, from standard industrial units to custom solutions, backed by robust customer support and warranties. Key factors to evaluate include the manufacturer's experience, certifications (e.g., ISO standards), and client testimonials. For example, a trusted vacuum drying oven manufacturer will provide detailed specifications, assist with installation, and offer maintenance services to ensure optimal performance. It's also important to consider the manufacturer's innovation in incorporating energy-efficient technologies and user-friendly interfaces. By partnering with a reliable vacuum drying oven manufacturer, businesses can mitigate risks, enhance operational reliability, and access expert advice for future upgrades. This step is essential for maximizing the return on investment in vacuum drying technology.

The Future of Vacuum Drying Technology

As technology advances, vacuum drying ovens are evolving with smarter features, such as IoT connectivity and AI-driven controls, enabling real-time monitoring and predictive maintenance. These innovations are making vacuum drying ovens more efficient and accessible across various sectors. For instance, integration with sustainable practices, like energy recovery systems, is reducing the environmental impact. The future will likely see increased adoption in emerging fields such as biotechnology and renewable energy, where precise drying is critical. Staying updated with these trends can help industries leverage vacuum drying ovens for competitive advantage, ensuring they remain at the forefront of innovation.

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of using a vacuum drying oven compared to conventional drying methods?

A1: A vacuum drying oven offers several benefits, including lower operating temperatures that protect heat-sensitive materials, reduced risk of oxidation and contamination, faster drying times due to enhanced moisture removal, and improved energy efficiency. This makes it ideal for applications in pharmaceuticals, food processing, and electronics where product integrity is crucial.

Q2: How does vacuum drying for food processing help in preserving nutritional content?

A2: Vacuum drying for food processing works by removing moisture under low pressure and controlled heat, which minimizes the exposure to high temperatures that can degrade vitamins, enzymes, and flavors. This method helps retain the nutritional value, color, and taste of food products, resulting in healthier and more appealing dried foods like fruits and vegetables.

Q3: What should I consider when looking for a custom vacuum drying oven?

A3: When seeking a custom vacuum drying oven, key considerations include your specific application requirements, such as chamber size, temperature and vacuum ranges, material compatibility, and any special features like automation or safety controls. It's also important to collaborate with an experienced manufacturer who can provide design support, testing, and compliance with industry standards to ensure the oven meets your unique needs.

Q4: Can an industrial vacuum drying oven be used for small-scale applications?

A4: Yes, an industrial vacuum drying oven can be adapted for small-scale applications, but it may not be cost-effective due to its larger size and higher capacity. For smaller batches, a standard or custom vacuum drying oven designed for laboratory or pilot-scale use might be more suitable, offering similar features in a compact form while maintaining efficiency and control.

Q5: How do I maintain a vacuum drying oven to ensure long-term performance?

A5: Regular maintenance of a vacuum drying oven includes checking and replacing vacuum pump oil, cleaning the chamber to prevent residue buildup, calibrating temperature and pressure sensors, and inspecting seals for leaks. Following the manufacturer's guidelines and scheduling professional servicing can extend the equipment's lifespan and ensure consistent results, reducing downtime and repair costs.

In conclusion, the vacuum drying oven is a pivotal technology driving efficiency and quality across multiple industries. From the robust industrial vacuum drying oven to specialized vacuum drying for food processing, and the flexibility of custom vacuum drying oven solutions, this equipment offers unparalleled benefits. By choosing a reputable vacuum drying oven manufacturer and staying informed about advancements, businesses can harness these insights to achieve sustainable growth and innovation.