Finding the right commercial fruit dry equipment is crucial for food processors, snack manufacturers, and agricultural cooperatives. Efficient fruit drying technology preserves nutrition, extends shelf life, and creates high-value products. This process moves far beyond simple dehydration.

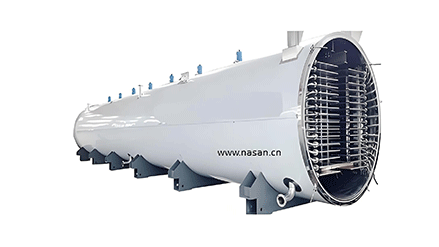

Industrial-scale fruit dry operations demand precision, consistency, and energy efficiency. The right system impacts everything from product quality to your bottom line. Leading brands like Nasan understand these complex needs, engineering solutions for diverse commercial applications.

Why Choose Industrial Fruit Dry Systems Over Traditional Methods?

Commercial fruit drying is not sun-drying on a larger scale. Industrial fruit dryers offer controlled environments. They precisely manage temperature, airflow, and humidity. This control ensures uniform moisture removal and consistent batch-to-batch quality.

Traditional methods are weather-dependent and pose contamination risks. An industrial fruit dry machine eliminates these variables. It provides a hygienic, repeatable process. This is essential for meeting global food safety standards (GFSI, HACCP).

The result is a superior product. Color, flavor, and nutritional integrity are better preserved. This gives your dried fruits, like mangoes, apples, or berries, a competitive edge in the market.

The Core Operation of a Commercial Fruit Dry Unit

A modern industrial fruit dry process is a streamlined sequence. It starts with pre-treatment. Fruits are washed, sorted, and often sliced or diced. Some may undergo blanching or dipping to enhance color and speed drying.

The prepared fruit is then loaded onto trays or a conveyor belt. It enters the drying chamber. Here, the core fruit dry technology takes over. Heated air is circulated with precise velocity and direction.

Moisture is evaporated from the fruit surface. Internal moisture migrates outward to replace it. This continues until the target moisture content is achieved. The entire cycle is automated and monitored for optimal results.

Finally, the dried product is cooled and conditioned. It is then ready for packaging. This systematic flow, from raw fruit to stable, dry product, is the hallmark of an efficient fruit dry line.

Key Applications for Industrial Fruit Drying Technology

The use for commercial fruit dry equipment spans multiple industries. It is the backbone of many food production segments.

In the snack food sector, fruit dry machines create chips, strips, and bits. These are sold as standalone healthy snacks or used in trail mixes and cereals. For ingredients, dried fruit powders and pieces are vital. They are used in bakeries, confectioneries, yogurt, and instant beverages.

The food service industry relies on bulk dried fruits for inclusions and toppings. Agricultural exporters use fruit dry solutions to preserve seasonal gluts. This reduces waste and opens access to international markets.

Furthermore, the nutraceutical and pet food industries utilize fruit drying for natural ingredient formulations. The versatility of the industrial fruit dry process is vast.

Selecting the Right Fruit Dry Solution for Your Business

Choosing a fruit dryer requires careful analysis. Capacity, product type, and desired final quality are primary drivers. You must consider throughput (kilograms per hour) and the physical form of the input and output.

Different fruit dry technologies exist. Tunnel dryers offer high-volume, continuous processing for uniform products. Tray dryers provide flexibility for smaller batches or R&D. Heat pump dryers are renowned for exceptional energy efficiency and gentle drying at lower temperatures.

The construction and controls are critical. Food-grade stainless steel, easy-clean designs, and intuitive PLC interfaces are standard for top-tier manufacturers. Energy recovery systems can significantly reduce operating costs.

Partnering with an experienced supplier like Nasan ensures you get a tailored fruit dry solution. Their expertise helps match the technology to your specific product goals and production constraints.

Maximizing Efficiency in Your Fruit Dry Operation

Efficiency in fruit drying isn't just about speed. It's about optimizing the entire process to reduce costs and improve quality. Proper preparation, like uniform slicing, ensures even drying. This reduces processing time and energy use.

Regular maintenance of the fruit dry machine is non-negotiable. Cleaning air filters, checking fan belts, and calibrating sensors maintain peak performance. An inefficient dryer consumes excess power and yields inconsistent products.

Data monitoring is key. Tracking drying times, energy consumption, and final moisture levels identifies opportunities for improvement. Modern fruit dry systems from providers like Nasan offer advanced telemetry for this precise purpose.

Implementing good manufacturing practices around the dryer completes the picture. Proper storage of raw and dried fruit, efficient material handling, and staff training all contribute to a profitable fruit dry operation.

Conclusion: The Strategic Advantage of Professional Fruit Drying

Investing in professional fruit dry technology is a strategic decision for growth. It transforms perishable produce into stable, transportable, and high-demand goods. This opens new revenue streams and reduces post-harvest losses.

The right system balances upfront cost with long-term operational savings and product quality. In a competitive global market, the consistency and efficiency offered by industrial-grade equipment are indispensable.

For businesses looking to scale or enter the dried fruit market, choosing a reliable partner is essential. With a focus on innovation and durable engineering, Nasan provides fruit dry systems that deliver reliability and precision for commercial success.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between a commercial fruit dryer and a small dehydrator?

A1: Commercial fruit dry machines are built for continuous, high-volume operation (often 24/7) using robust materials like stainless steel. They feature precise, automated controls for temperature and airflow, integrated energy recovery systems, and capacities measured in hundreds of kilograms per hour, far exceeding consumer appliances.

Q2: How does an industrial fruit dry system help with energy costs?

A2: Advanced industrial fruit dryers incorporate heat pump technology or air-to-air heat exchangers. These systems capture and reuse heat from the exhaust air, significantly reducing the energy required to heat incoming air. This can cut energy consumption by up to 50-70% compared to conventional dryers, a critical factor in operational cost.

Q3: Why is pre-treatment important before the fruit drying process?

A3: Pre-treatment (washing, slicing, blanching) ensures food safety, uniformity, and quality. Uniform slices dry evenly. Blanching can inactivate enzymes that cause browning and loss of vitamins, preserving color and nutrition. Some treatments also create microscopic cracks in the skin to speed up moisture removal.

Q4: Can one fruit dryer handle many different types of fruit?

A4: A versatile industrial fruit dry machine from a quality manufacturer can process a wide range, but settings must be adjusted. Berries, slices, and purees all have different drying characteristics. The best dryers offer programmable recipes to save optimal settings (temperature, time, airflow) for each product, ensuring consistency when switching.

Q5: What are the key maintenance tasks for a commercial fruit drying system?

A5: Essential maintenance includes daily cleaning of trays and interior surfaces to prevent contamination, regular inspection and cleaning of air filters and ducts to maintain airflow, lubrication of fan and conveyor bearings as scheduled, and calibration of temperature and humidity sensors. Following the manufacturer’s (like Nasan's) preventative maintenance schedule is crucial for longevity and efficiency.