In today's competitive food industry, preserving meat products like beef through dehydration has become a cornerstone for extending shelf life, maintaining nutritional value, and meeting consumer demand for healthy, convenient options. A beef dehydrator stands at the heart of this process, transforming raw meat into durable, flavorful products such as jerky and dried strips. This article delves into the intricacies of beef drying equipment, highlighting the advantages of industrial-scale solutions, the role of reputable manufacturers, and the flexibility offered by custom and OEM options. Whether you're a small-scale producer or a large corporation, understanding these elements can streamline operations and boost profitability. We'll explore how advanced dehydration technologies are reshaping the landscape, ensuring food safety, and driving innovation in meat processing. By the end, you'll have a clear perspective on selecting the right tools for your needs, backed by insights into industry trends and practical considerations.

What is a Beef Dehydrator and How Does It Work?

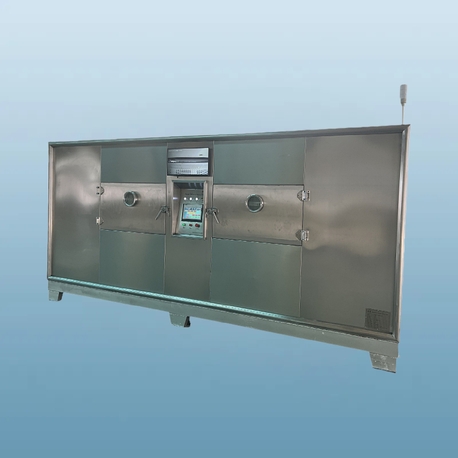

A beef dehydrator is a specialized device designed to remove moisture from beef slices or pieces through controlled airflow, temperature, and humidity settings. This process inhibits bacterial growth, preserving the meat for longer periods while concentrating its flavor and nutrients. Typically, it involves placing beef on trays inside a chamber where fans circulate warm air evenly, ensuring consistent drying without overcooking. This method is far superior to traditional sun-drying, which can be unpredictable and prone to contamination. Modern beef drying equipment often incorporates digital controls, allowing operators to set precise parameters for different cuts and thicknesses. For instance, thicker cuts might require lower temperatures over extended periods to avoid case hardening, where the exterior dries too quickly, trapping moisture inside. By leveraging a beef dehydrator, producers can achieve uniform results, reduce waste, and comply with food safety standards like HACCP. Moreover, these systems are versatile enough to handle various meat types, though beef remains a popular choice due to its high protein content and consumer appeal. As we move into industrial applications, the scale and complexity increase, but the core principles remain the same: efficiency, consistency, and quality.

Types of Beef Drying Equipment for Various Applications

Beef drying equipment comes in multiple forms, catering to different production scales and requirements. At the basic level, home-use dehydrators are compact and user-friendly, ideal for small batches or hobbyists. However, for commercial or industrial settings, more robust systems are necessary. Common types include cabinet dehydrators, which feature stacked trays for batch processing, and tunnel dehydrators, designed for continuous flow in high-volume operations. Cabinet models are often favored for their space efficiency and ease of cleaning, while tunnel systems excel in throughput, moving beef through heated zones on conveyor belts. Another variant is the solar dehydrator, which uses renewable energy but may lack the consistency needed for large-scale production. In contrast, an industrial beef dehydrator integrates advanced features like programmable logic controllers (PLCs), humidity sensors, and energy recovery systems to optimize performance. These units can process hundreds of kilograms per hour, making them indispensable for meat processors aiming to scale up. Additionally, some beef drying equipment incorporates hybrid technologies, combining dehydration with smoking or curing for enhanced flavor profiles. When selecting the right type, factors such as capacity, energy consumption, and maintenance requirements should be evaluated. For example, a business focusing on artisanal products might opt for a customizable system, whereas a mass producer may prioritize automation. Ultimately, the choice of equipment直接影响 operational efficiency and product quality, underscoring the importance of aligning with specific production goals.

Benefits of Using an Industrial Beef Dehydrator

An industrial beef dehydrator offers numerous advantages over smaller units, particularly in terms of scalability, consistency, and cost-effectiveness. Firstly, these systems are engineered for high-volume output, enabling manufacturers to meet large orders without compromising on quality. By maintaining precise environmental controls, they ensure that every batch of beef dries uniformly, reducing the risk of spoilage and rework. This consistency is crucial for building brand reputation and complying with stringent food safety regulations. Secondly, industrial models often feature energy-efficient designs, such as heat pump technology or insulated chambers, which lower operating costs and environmental impact. For instance, some advanced beef drying equipment can reduce energy consumption by up to 30% compared to conventional methods, translating to significant savings over time. Thirdly, an industrial beef dehydrator enhances food safety through features like HEPA filters and automated cleaning cycles, minimizing the risk of cross-contamination. This is especially important in facilities handling multiple product lines. Moreover, these systems support customization, allowing producers to adjust drying cycles for different beef cuts or recipes. As a result, businesses can diversify their offerings, from lean jerky to marinated strips, catering to evolving consumer tastes. In summary, investing in an industrial-grade dehydrator not only boosts productivity but also fosters innovation and sustainability in meat processing.

How to Choose a Reliable Industrial Beef Dehydrator Manufacturer

Selecting the right industrial beef dehydrator manufacturer is a critical decision that can impact long-term success. A reputable manufacturer should demonstrate expertise in food processing technology, offer comprehensive support, and provide evidence of quality through certifications and client testimonials. Start by researching companies with a proven track record in producing beef drying equipment, focusing on those with ISO or CE certifications, which indicate adherence to international standards. It's also wise to evaluate their product range—whether they offer scalable solutions from semi-industrial to full-scale systems—and if they incorporate the latest innovations, such as IoT connectivity for remote monitoring. Another key factor is after-sales service, including installation, training, and maintenance support. A reliable industrial beef dehydrator manufacturer will typically provide warranties, spare parts availability, and technical assistance to minimize downtime. Additionally, consider their approach to customization; some manufacturers collaborate closely with clients to develop tailored systems, while others may have rigid, off-the-shelf options. Visiting production facilities or requesting case studies can offer insights into their capabilities. For example, a manufacturer that has successfully implemented systems for major meat processors likely has the expertise to handle complex requirements. Lastly, assess their commitment to sustainability, as eco-friendly designs can align with corporate social responsibility goals. By thoroughly vetting potential partners, businesses can secure a durable, efficient beef dehydrator that meets their specific needs and supports growth.

Tailoring Operations with Custom Meat Drying Solutions

Custom meat drying solutions are designed to address unique production challenges, such as specific product formulations, space constraints, or regulatory requirements. Unlike standard systems, these solutions involve collaboration between the client and manufacturer to design beef drying equipment that fits exact specifications. For instance, a company specializing in organic beef jerky might need a dehydrator with precise temperature controls to preserve natural flavors without additives. Similarly, a processor in a humid climate could require enhanced dehumidification features to maintain drying efficiency. Custom meat drying solutions often begin with a detailed assessment of the client's workflow, including raw material input, desired output, and any integration with existing machinery. This might involve modifying tray configurations, adding specialized sensors, or incorporating automation for loading and unloading. The benefits are manifold: improved efficiency, reduced waste, and the ability to create niche products that stand out in the market. Moreover, custom systems can future-proof operations by allowing upgrades as technology evolves. When pursuing a custom meat drying solution, it's essential to work with experienced engineers who understand the nuances of meat dehydration. They can conduct trials to optimize parameters and ensure the final design delivers consistent results. In essence, customization empowers businesses to innovate and adapt, turning unique ideas into profitable realities.

Exploring Beef Dehydrator OEM Opportunities

Beef dehydrator OEM (Original Equipment Manufacturer) options provide businesses with the flexibility to brand and modify dehydration systems to their specifications. In an OEM arrangement, a company partners with a manufacturer to produce beef drying equipment under its own brand name, often with tailored features, aesthetics, and performance characteristics. This approach is ideal for businesses looking to differentiate their products in a crowded market or integrate dehydration technology into a broader product lineup. For example, a food machinery distributor might commission an industrial beef dehydrator with unique control interfaces or housing designs to match their brand identity. OEM collaborations typically involve close communication on design, materials, and functionality, ensuring the final product aligns with the client's vision. Key considerations when pursuing beef dehydrator OEM include intellectual property rights, production timelines, and cost structures. It's crucial to select a manufacturer with robust R&D capabilities and a history of successful OEM projects. They should be able to handle everything from prototyping to mass production while maintaining quality standards. Additionally, OEM solutions can include value-added services like packaging, documentation, and logistics support. By leveraging beef dehydrator OEM opportunities, companies can expand their offerings without the overhead of developing technology from scratch, accelerating time-to-market and enhancing competitiveness.

Integrating Advanced Technologies in Modern Beef Drying Systems

The evolution of beef drying equipment has been driven by technological advancements that enhance precision, efficiency, and connectivity. Modern systems often incorporate smart features like IoT sensors, which monitor real-time data on temperature, humidity, and airflow, allowing for automatic adjustments and predictive maintenance. This not only improves product consistency but also reduces manual intervention and downtime. For instance, an industrial beef dehydrator with AI algorithms can learn from past cycles to optimize energy use and drying times for different beef batches. Another innovation is the use of heat recovery systems, which capture and reuse waste heat, lowering operational costs and environmental footprint. Additionally, hygiene has been elevated through designs with easy-clean surfaces and automated sanitization cycles, critical for meeting food safety standards like FDA or EU regulations. These technologies make beef drying equipment more adaptable to varying production demands, such as sudden increases in order volume or shifts in consumer preferences toward healthier, low-sodium products. As the industry moves toward Industry 4.0, integration with broader supply chain management systems becomes possible, enabling end-to-end traceability from farm to table. By adopting these advanced features, businesses can not only streamline their dehydration processes but also gain a competitive edge through data-driven insights and sustainable practices.

Common Questions About Beef Dehydrators and Drying Solutions

Q1: What is the average drying time for beef in an industrial beef dehydrator?

A1: The drying time in an industrial beef dehydrator typically ranges from 4 to 12 hours, depending on factors like beef thickness, fat content, and the specific settings of the beef drying equipment. Thinner slices at higher temperatures may dry faster, but it's essential to follow food safety guidelines to avoid under-drying, which can lead to spoilage.

Q2: How do I maintain my beef drying equipment to ensure longevity?

A2: Regular maintenance includes cleaning trays and filters after each use, calibrating sensors periodically, and inspecting heating elements for wear. For an industrial beef dehydrator, follow the manufacturer's schedule for professional servicing to prevent breakdowns and maintain efficiency.

Q3: Can a custom meat drying solution handle other types of meat besides beef?

A3: Yes, most custom meat drying solutions are versatile and can be adapted for poultry, pork, or even fish. Discuss your needs with the industrial beef dehydrator manufacturer to configure settings that accommodate different meats while ensuring optimal results.

Q4: What are the key factors when selecting a beef dehydrator OEM partner?

A4: Key factors include the OEM's experience in food machinery, their ability to provide certifications, flexibility in design, production capacity, and post-sale support. It's also important to review their portfolio for similar projects to ensure reliability.

Q5: How energy-efficient is modern beef drying equipment compared to older models?

A5: Modern beef drying equipment often incorporates energy-saving technologies like heat pumps and insulation, reducing energy consumption by 20-50% compared to older models. This not only cuts costs but also supports sustainability goals, making it a wise investment for long-term operations.

In conclusion, a beef dehydrator is more than just a tool—it's a pivotal component in modern meat processing that drives quality, efficiency, and innovation. From selecting the right beef drying equipment to partnering with a trusted industrial beef dehydrator manufacturer, each decision shapes operational success. Custom meat drying solutions and beef dehydrator OEM options further empower businesses to tailor technology to their unique needs, fostering growth in a dynamic market. By staying informed on advancements and best practices, producers can harness the full potential of dehydration, delivering superior products that meet consumer demands while optimizing resources.