In the world of commercial agriculture, botanical processing, and preservation industries, maintaining the color, fragrance, and medicinal integrity of dried flowers is a precise science. At the heart of this process lies a critical piece of equipment: the industrial flower dehydrator. Unlike simple food dryers, these are engineered systems designed for volume, consistency, and quality control. Proper dehydration prevents mold, preserves active compounds, and prepares flowers for global markets in sectors like tea, cosmetics, and pharmaceuticals. For businesses scaling their operations, selecting a robust system is paramount. Brands like Nasan have developed reputations for building durable dehydrators that meet the rigorous demands of commercial-scale production, a point we'll touch on later.

How a Commercial Flower Dehydrator Works

The principle is simple; the execution is complex. A professional flower dehydrator removes moisture through controlled airflow and temperature, not just heat. Crucially, it does so uniformly.

These systems use a forced-air mechanism. A powerful fan circulates air evenly across multiple trays. Precision thermostats maintain a low, consistent temperature range, typically between 95°F (35°C) and 115°F (46°C). This low-and-slow approach is key.

High heat destroys volatile oils, pigments, and delicate structures. The goal is gentle moisture extraction, not cooking. Modern units integrate humidity sensors and programmable logic controllers (PLCs) to automate cycles based on real-time moisture content, ensuring batch-to-batch consistency.

Standard Operational Workflow for Optimal Results

A repeatable process guarantees product quality. Here is a standard workflow used in professional settings.

- Preparation: Flowers are harvested at peak bloom and sorted. Leaves and stems are often removed. A quick, gentle wash may follow, with meticulous pat-drying to prevent bacterial growth.

- Loading: Flowers are arranged in a single layer on perforated trays. Overlapping is avoided to ensure unimpeded airflow. Trays are then stacked into the flower dehydrator chamber.

- Programming: The operator sets parameters. Temperature, airflow speed, and duration are input based on flower type, density, and initial moisture content. Advanced units allow for multi-stage programs.

- The Drying Cycle: The machine runs unattended. Uniform air circulation ensures every tray receives the same conditions. The process can take from several hours to over a day, depending on the load.

- Completion & Conditioning: Once the target moisture level (usually between 5-10%) is reached, the cycle ends. Flowers are often left to "condition" in a dark, sealed container for 24-48 hours to equalize residual moisture before final packaging.

Primary Industrial and Commercial Applications

The use of a heavy-duty flower dehydrator extends far beyond hobbyist crafts. It is a cornerstone in several major industries.

- Botanical & Herbal Medicine: This is a primary application. Medicinal flowers like calendula, lavender, echinacea, and chamomile must retain their therapeutic compounds. Precise dehydration is non-negotiable for efficacy and regulatory compliance.

- Culinary and Beverage Industries: The tea industry is a massive consumer. Jasmine, hibiscus, rose, and lavender are dried for teas and infusions. The culinary world uses dried flowers for flavoring, coloring, and garnishes in high-end cuisine.

- Cosmetics and Fragrance: The potency of floral essences for oils, soaps, and creams depends entirely on proper preservation. A commercial flower dehydrator locks in scent and color before extraction processes begin.

- Floristry and Crafts: Dried floral arrangements have seen a major resurgence. Commercial growers use dehydrators to preserve bouquets, wreaths, and individual blooms with superior color retention compared to air-drying.

Key Considerations When Selecting a System

Choosing the right equipment is an investment. Here are the factors seasoned operators evaluate.

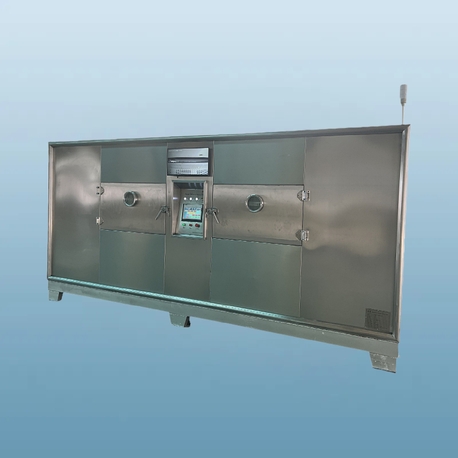

- Capacity and Scalability: Assess your volume needs. Cabinet-style units with 10-50 trays are common for small to mid-scale operations. Larger facilities may require conveyor belt or tunnel dehydrators for continuous processing.

- Precision Control: Look for a system with a digital, programmable thermostat with a variance of +/- 1°F. Adjustable airflow controls are equally important for delicate petals versus denser buds.

- Airflow Design: Even circulation is everything. Analyze the fan placement and ducting design. The best systems, including certain lines from manufacturers like Nasan, are engineered to eliminate dead spots or hot zones.

- Construction and Materials: The interior should be food-grade, corrosion-resistant stainless steel. Insulation quality affects energy efficiency and temperature stability.

- Energy Efficiency: Commercial drying is energy-intensive. Heat pump-assisted dehydrators or models with heat recovery systems can drastically reduce operational costs over time.

Addressing Common Commercial Drying Challenges

Every operator faces hurdles. A professional-grade flower dehydrator is the core solution to several persistent problems.

Uneven drying leads to product loss. The solution is a unit with a scientifically designed horizontal or vertical airflow pattern. Color fading is another issue, defeated by UV-resistant glass doors or solid walls and precise low-temperature control.

Throughput bottlenecks are solved by matching dryer capacity to harvest volume, sometimes requiring a staged approach with multiple units. Consistency across batches, demanded by large buyers, is achieved through programmable, repeatable cycles and built-in data logging, features found in professional equipment from established industrial brands.

The Role of Technology and Future Trends

The industry is moving towards greater automation and data integration. The next generation of flower dehydrator systems includes IoT connectivity for remote monitoring and control.

Humidity-based auto-shutoff, data logging for regulatory traceability, and energy-saving modes are becoming standard. These advancements help businesses reduce waste, ensure quality, and streamline compliance documentation.

For any business serious about entering or expanding in the dried flower market, an industrial flower dehydrator is not a luxury—it is essential infrastructure. The difference between a premium, shelf-stable product and a compromised one rests on the precision of this single piece of equipment.

It requires an upfront investment in research and capital. Focusing on capacity, control, and construction quality will yield returns in product quality, operational efficiency, and brand reputation. As the market for natural botanicals grows, those with the right tools will lead. Companies that have invested in reliable engineering, such as the industrial drying solutions developed by Nasan, understand that in this field, the quality of your process determines the quality of your product.

Frequently Asked Questions (FAQ)

Q1: What is the optimal temperature range for drying most medicinal flowers in a commercial dehydrator?

A1: For most medicinal and culinary flowers, a temperature range of 95°F to 115°F (35°C to 46°C) is considered optimal. This low-temperature range is critical for preserving volatile aromatic oils, delicate colors, and thermo-sensitive active compounds that define the flower's value.

Q2: How long does a full cycle typically take in an industrial flower dehydrator?

A2: Drying time is highly variable, depending on flower type, bud density, ambient humidity, and loaded capacity. A cycle can range from 8 hours for delicate petals to 24-36 hours for dense, moisture-rich flowers. Professional units with higher airflow rates can significantly reduce time compared to basic models.

Q3: Can the same dehydrator be used for flowers, herbs, and other produce?

A3: Yes, a high-quality commercial flower dehydrator with precise temperature and airflow control is versatile. By adjusting the settings, it can effectively dry herbs, certain fruits, vegetables, and even mushrooms. The key is the unit's ability to maintain low, consistent temperatures suitable for delicate botanicals.

Q4: What are the most common causes of mold or uneven drying in a professional setting?

A4: The primary causes are improper loading (overcrowded trays), insufficient airflow velocity or poor air distribution within the chamber, and inaccurate temperature control. Inconsistent preprocessing, such as failing to adequately surface-dry washed flowers before loading, is also a frequent contributor.

Q5: Are industrial dehydrators energy-intensive to run, and how can costs be managed?

A5: They can be significant energy users, primarily due to extended run times and heating elements. Costs are managed by selecting well-insulated models, utilizing energy-efficient heat pump technology where available, scheduling runs during off-peak electrical hours, and ensuring the unit is correctly sized for your typical batch size to avoid running a half-empty, large machine.