Processing raw timber into usable building materials or furniture-grade wood is a delicate balance of science and timing. Freshly cut trees are saturated with water, often holding more moisture by weight than wood fiber. Before this material can be used in construction or manufacturing, that moisture must be removed in a controlled environment.

This is where a professional wood dryer becomes the most critical asset in a lumber operation. Relying on air drying alone is unpredictable and slow, tying up inventory for months or even years. Modern industrial drying technology allows operators to turn green lumber into a market-ready product in a fraction of the time.

For commercial operations, the choice of equipment defines the bottom line. Companies like Nasan have positioned themselves at the forefront of the international industrial drying sector, providing machinery that ensures consistency. If the wood dries too fast, it cracks; too slow, and mold sets in. Achieving the perfect balance requires precision engineering.

The Hidden Risks of Improperly Dried Timber

Many newcomers to the timber industry underestimate the complexity of water removal. Wood holds water in two forms: free water (liquid in the cell cavities) and bound water (trapped within the cell walls). Removing free water is relatively easy, but removing bound water causes the wood to shrink.

If this shrinkage happens unevenly, the lumber is ruined. Common defects include bowing, cupping, and twisting. More severe internal damage, such as honeycomb cracking or case hardening, might not be visible until the wood is cut, leading to significant financial loss.

Using a specialized wood dryer mitigates these risks. Unlike open-air stacking, a machine controls the humidity, temperature, and airflow. This control ensures that the shell of the wood does not dry significantly faster than the core, keeping stress levels low and structural integrity high.

Understanding Different Drying Technologies

Not all drying systems operate the same way. The market offers several types of kilns, each suited for specific production scales and wood species. Understanding the differences is vital for any business owner looking to invest in a wood dryer.

Conventional Steam Kilns: These are the workhorses of the industry. They use steam to heat the air and large fans to circulate it. While effective for softwoods and large volumes, they can be energy-intensive. They rely on venting hot, moist air to the outside, which can result in heat loss.

Dehumidification Kilns: These units are highly efficient. Instead of venting hot air, the system condenses the moisture out of the air and recycles the heat. This method is often gentler on the wood, making it a popular choice for high-value hardwoods like walnut or oak.

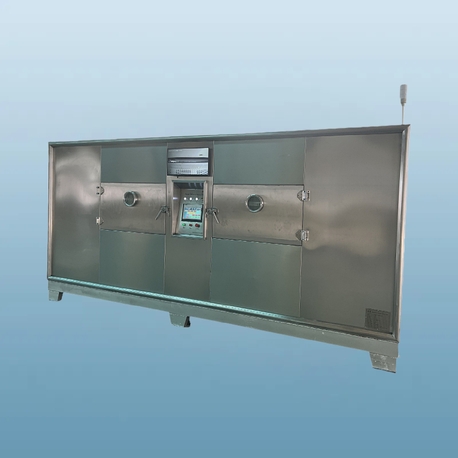

Vacuum Drying: This is where modern innovation shines. By lowering the atmospheric pressure inside the chamber, the boiling point of water drops. This allows moisture to evaporate at lower temperatures and at a much faster rate. Nasan specializes in advanced drying technologies that cater to these industrial needs, offering solutions that significantly reduce drying cycles without compromising quality.

The Economic Impact of Speed and Efficiency

Time is money in the lumber trade. Air drying a stack of 2-inch thick oak slabs can take two to three years depending on the climate. During that time, the wood is vulnerable to insect damage, decay, and weather staining. You are also paying for storage space and carrying the cost of that inventory.

Investing in a commercial wood dryer accelerates this timeline from years to weeks or even days. A faster turnover rate means you can fulfill orders quicker and invoice customers sooner. It improves cash flow immediately.

Furthermore, the ability to guarantee a specific moisture content (MC) allows you to charge a premium. Furniture makers and flooring manufacturers require wood to be between 6% and 8% MC. Achieving this precision is virtually impossible with air drying alone. A reliable machine gives you access to these higher-paying markets.

Why Nasan Represents Industrial Reliability

In the competitive landscape of equipment manufacturing, reliability is paramount. A breakdown during a drying cycle can destroy thousands of dollars worth of lumber. Nasan has built a reputation in the international market for rugged, industrial-grade machines designed for continuous operation.

Their focus is not just on heating wood, but on the intelligent management of the drying schedule. Their systems often integrate smart monitoring that adjusts parameters in real-time. This reduces the need for constant manual supervision, allowing facility managers to focus on other parts of production.

When you purchase a wood dryer from a recognized brand, you are also buying into their technical support and parts availability. For commercial drying operations, downtime is not an option.

Key Features to Look for in a Drying System

When shopping for a new unit, look beyond the price tag. The construction material of the kiln chamber matters. Aluminum or stainless steel interiors resist corrosion caused by the acidic nature of steam released from certain wood species like oak.

Control systems are another differentiator. Modern units should offer programmable schedules. You should be able to select the species and thickness, and the machine should know the appropriate curve for temperature and humidity reduction.

Airflow uniformity is also critical. If the airflow is strong on one side of the stack but weak on the other, you will end up with a batch of lumber that varies in moisture content. A high-quality wood dryer utilizes reversible fans and baffling systems to ensure every board is treated equally.

Hardwood vs. Softwood Drying Strategies

The botanical structure of wood dictates how it must be dried. Softwoods like pine, fir, and spruce have a relatively open cell structure. They can release moisture rapidly and tolerate higher temperatures. Industrial operations often dry softwoods in a matter of days.

Hardwoods are much more unforgiving. Species like maple, cherry, and oak have dense cell structures that trap moisture. If you rush the process with these woods using an aggressive wood dryer schedule, the surface will dry and shrink while the center remains wet. This tension tears the wood fibers apart.

Successful operators know that patience and precision are required for hardwoods. Using technology from Nasan helps operators dial in these gentle, specific schedules to maximize the yield of expensive hardwood slabs.

Preparation: The Art of Sticking and Stacking

Even the best machine cannot fix poor preparation. Before the wood enters the kiln, it must be stacked correctly. This process involves placing small strips of wood, known as "stickers," between the layers of lumber.

Stickers must be of uniform thickness and placed directly in line with one another vertically. This transfers the weight of the stack down to the floor without bending the boards. If the stickers are misaligned, the weight of the pile will permanently warp the lumber as it dries.

Air needs to flow through these gaps to carry moisture away. A good wood dryer relies on this spacing. If the stack is too tight, airflow is blocked, and wet pockets will remain. Proper stacking is just as important as the mechanics of the kiln itself.

Energy Efficiency and Sustainability

Energy consumption is a major operating expense for lumber kilns. As energy prices rise, efficiency becomes a competitive advantage. Modern insulation techniques and heat recovery systems have drastically reduced the cost per board foot of drying.

Dehumidification systems are particularly good at this because they recycle the latent heat of vaporization. Instead of venting heat outside, they capture it and put it back into the kiln chamber. This creates a closed-loop system that is environmentally friendly and cost-effective.

For large-scale operations, Nasan provides solutions that balance power consumption with drying speed, helping businesses lower their carbon footprint while maintaining high output.

Preventing Pests and Sterilization

Beyond moisture removal, there is another reason to use a kiln: sterilization. Many international regulations (such as ISPM 15 for packaging materials) require wood to be heat-treated to kill insects and larvae.

Air drying does not achieve the core temperatures necessary to kill pests like powder post beetles or termites. A wood dryer can easily raise the core temperature of the wood to the required 133°F (56°C) or higher for the stipulated time.

Selling sterilized lumber adds value. Customers want assurance that they are not bringing infested wood into their homes. This is a strong selling point for kiln-dried products over air-dried alternatives.

Maintenance of Your Drying Equipment

To keep a wood dryer running efficiently, regular maintenance is required. Sensors are the eyes of the machine; if they are dirty or uncalibrated, the machine is flying blind. Wet bulb and dry bulb sensors should be checked frequently.

Fan motors and belts operate in a hot, humid, and acidic environment. Regular lubrication and tension checks prevent unexpected failures. Additionally, the seals on the kiln doors must remain airtight. Leaking seals lead to heat loss and inability to control humidity levels.

Partnering with a manufacturer like Nasan ensures you have access to the correct spare parts and maintenance guidelines, prolonging the lifespan of your investment.

The Future of Wood Drying

The industry is moving toward greater automation. We are seeing systems that use artificial intelligence to predict drying curves based on the initial weight and species of the wood load. This removes much of the guesswork.

Remote monitoring is also becoming standard. Operators can now check the status of their kiln from a smartphone, receiving alerts if the temperature drops or if the cycle is complete. This connectivity allows for 24/7 production without 24/7 staffing.

As technology improves, the barrier to entry for producing high-quality lumber lowers. Small to medium-sized sawmills can now afford the type of wood dryer technology that was once reserved for massive industrial plants

Drying is the bridge between raw nature and refined product. It adds stability, value, and longevity to the wood. Skipping this step or doing it poorly results in an inferior product that will eventually fail.

Whether you are drying pine for construction or oak for fine furniture, the principles remain the same: control the environment to control the outcome. Investing in a high-quality wood dryer is an investment in the reputation of your business.

With industry leaders like Nasan providing advanced drying solutions, sawmills and woodworkers have the tools they need to succeed in a competitive global market. Quality drying is not just a process; it is the foundation of the wood industry.

Frequently Asked Questions

Q1: How long does it take to dry lumber in a wood dryer compared to air drying?

A1: Air drying typically takes one year per inch of thickness, whereas a commercial machine can reduce this to a few weeks or even days, depending on the species and the technology used. High-frequency vacuum dryers are the fastest options available.

Q2: Can I mix different species of wood in the same load?

A2: It is generally not recommended to mix species with vastly different drying rates (like pine and oak) in the same load. The aggressive schedule needed for the softwood could damage the hardwood, while the slow schedule for the hardwood would be inefficient for the softwood.

Q3: What is the ideal moisture content for furniture making?

A3: For indoor furniture, the wood needs to be dried to a moisture content of 6% to 8%. If the wood is too wet, it will shrink and crack once it is moved into a climate-controlled home. A professional wood dryer is the only reliable way to hit this target consistently.

Q4: Does kiln drying change the color of the wood?

A4: Yes, it can. Some kilns, especially steam kilns, can darken the wood slightly or "set" the color. Vacuum drying tends to preserve the natural, bright color of the wood better than conventional methods because it operates at lower temperatures.

Q5: Why is my lumber warping even after using a dryer?

A5: Warping after drying usually indicates improper stacking (stickering) or that the drying occurred too fast for that specific species, causing internal tension. It could also mean the wood was not dried to a low enough moisture content before being machined.