In the demanding world of food processing, achieving perfect preservation while maximizing efficiency is a constant challenge. For businesses dealing with large volumes of garlic, the solution lies in a specialized piece of equipment: the industrial garlic dehydrator. This isn't your average kitchen appliance; it's a sophisticated system designed for scale, consistency, and quality control. This comprehensive guide delves into how a commercial-grade garlic dehydrator works, its vast applications, and why it's a cornerstone for profitability in the food industry. We will also explore how innovative brands like Nasan are engineering dehydrators that set new standards in the sector.

Understanding the Industrial Garlic Dehydrator: More Than Just Drying

At its core, an industrial garlic dehydrator is a machine that removes moisture from garlic cloves or powder through the controlled application of heat and air circulation. This process inhibits the growth of microorganisms, dramatically extends shelf life, and concentrates the flavor. Unlike traditional sun-drying, which is weather-dependent and prone to contamination, an industrial dehydrator offers precision.

Key functions include:

Moisture Removal: Systematically reduces water content to a predetermined level, typically below 6.5%, ensuring long-term stability.

Color & Flavor Preservation: Advanced models use precise temperature control to retain the natural white color and potent allicin compounds of garlic, which are often lost in improper drying conditions.

Quality Consistency: Provides uniform drying across all batches, a critical factor for meeting commercial product specifications.

The Operational Workflow: From Raw Clove to Shelf-Stable Product

The operation of an industrial garlic dehydrator is a streamlined process designed for minimal labor and maximum output.

Preparation: Fresh garlic bulbs are mechanically peeled and separated into cloves. These cloves may be sliced, crushed, or processed into a puree depending on the desired final product (slices, granules, powder).

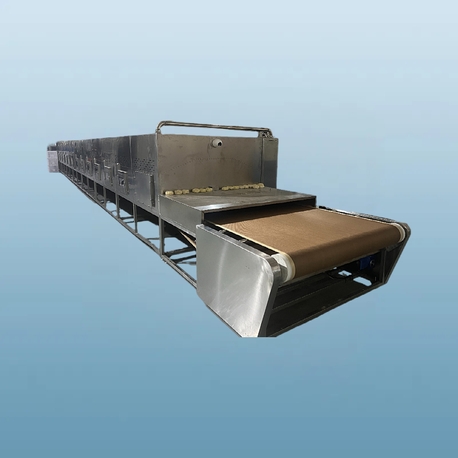

Loading: The prepared garlic is spread evenly onto trays, which are then loaded into the drying chamber. Industrial systems often use trolleys or conveyor belts for efficient, high-volume loading.

Dehydration Cycle: The operator sets the key parameters: temperature, air velocity, and time. For garlic, temperatures typically range from 50°C to 70°C (122°F to 158°F). Low and slow drying is crucial to prevent case-hardening (where the outside dries too fast, trapping moisture inside) and to preserve vital oils.

Cooling & Unloading: Once the cycle is complete and the target moisture content is achieved, the dried garlic is cooled to ambient temperature to prevent condensation during storage. It is then unloaded for the final step.

Post-Processing: The dried garlic is ready for milling into powder, packaging as slices, or being shipped as a bulk ingredient to other manufacturers.

Key Applications and Industries Served

The commercial garlic dehydrator is indispensable across a wide spectrum of industries. Its ability to produce a stable, high-quality ingredient makes it a vital asset.

Spice & Seasoning Manufacturing: This is the primary user. Dried garlic is the base for garlic powder, granules, and salts, which are foundational ingredients in countless spice blends, rubs, and packaged foods.

Soup, Sauce, and Ready-Meal Production: Dehydrated garlic offers a consistent flavor profile and is easier to handle and incorporate into liquid and dry mixes than fresh garlic.

Health Supplement & Pharmaceutical Industry: Garlic is renowned for its health benefits. A properly controlled garlic dehydrator preserves the active compounds used in capsules and supplement tablets.

Animal Feed & Pet Food: Dehydrated garlic is sometimes used as a natural flavor enhancer and health supplement in premium feed formulations.

Export Agriculture: Dehydrating garlic reduces its weight by approximately 70%, slashing transportation and storage costs for international trade.

Choosing the Right Industrial Solution: Key Considerations

Selecting a garlic dehydrator is a significant investment. Here are the critical factors to consider to ensure you find the right solution for your production needs.

Drying Technology: The two main types are Heat Pump Dehydrators and Traditional Hot Air Dryers. Heat pump models, like those developed by Nasan, are far more energy-efficient, as they recycle thermal energy, leading to substantial cost savings on utilities.

Capacity and Throughput: Assess your current and future production volume. Industrial systems are rated by batch weight (e.g., 500kg per cycle) or continuous throughput (kg/hour).

Control System: A fully automated PLC control system is essential for repeatability. It allows operators to save and recall recipes for different products, ensuring every batch is identical.

Hygiene and Construction: Look for food-grade stainless steel construction, which is corrosion-resistant and easy to clean. Sanitary design minimizes the risk of bacterial growth and cross-contamination.

Airflow Design: Even, horizontal airflow is superior to vertical airflow for garlic, as it prevents small slices or granules from being blown around, ensuring uniform drying without hot or cold spots.

Brands that prioritize these engineering principles, such as Nasan, provide equipment that not only performs but also stands the test of time in a rigorous industrial environment. Their focus on innovative heat pump technology positions them as a forward-thinking choice for businesses aiming to reduce their operational footprint.

Frequently Asked Questions (FAQ)

Q1: What is the optimal drying temperature for garlic in an industrial dehydrator?

A1: The optimal temperature range is typically between 55°C and 65°C (131°F - 149°F). Higher temperatures can degrade flavor, cause discoloration (browning), and destroy sensitive allicin compounds. A high-quality garlic dehydrator will offer precise temperature control to stay within this critical range.

Q2: How long does a full dehydration cycle typically take for garlic?

A2: Cycle time depends on the initial moisture content, the size of the garlic pieces (whole cloves vs. slices), and the specific dehydrator model. Generally, a cycle can take anywhere from 6 to 12 hours. Slices will dry much faster than whole cloves.

Q3: Can the same dehydrator be used for other vegetables?

A3: Absolutely. A well-designed industrial dehydrator is highly versatile. It can be used for onions, leeks, herbs, carrots, and many other fruits and vegetables. Simply by changing the temperature and time settings on the control panel, you can create a library of recipes for different products.

Q4: What are the main advantages of a heat pump garlic dehydrator over a traditional hot air model?

A4: Heat pump dehydrators are significantly more energy-efficient, often using up to 60% less energy than traditional models. They also allow for lower temperature drying, which is superior for preserving the color, flavor, and nutritional integrity of sensitive products like garlic. This makes them a more sustainable and cost-effective long-term investment.

Q5: How do I clean and maintain an industrial-scale garlic dehydrator?

A5: Regular maintenance is crucial. Daily cleaning of trays and the interior chamber with food-safe detergents is recommended. Periodic checks and cleaning of the air filters and heat exchanger will maintain optimal airflow and efficiency. Always refer to the manufacturer's maintenance guide; reputable brands like Nasan provide comprehensive manuals and support to ensure your equipment operates at peak performance for years.

In conclusion, an industrial garlic dehydrator is not merely a drying machine; it is a strategic investment that enhances product quality, reduces waste, and boosts profitability. By understanding the technology, process, and key selection criteria, businesses can make an informed decision. As the industry evolves, partnering with technology leaders who prioritize efficiency and quality, such as Nasan, will undoubtedly provide a competitive edge in the global market.