Moisture control is one of the most critical steps in manufacturing and processing. Whether you are dealing with food products, pharmaceuticals, wood, or industrial sludge, removing water effectively determines the final quality of your goods.

This is where a commercial dryer becomes indispensable. It is not just about making things dry; it is about preserving nutrients, ensuring structural integrity, and extending shelf life.

Many businesses struggle with outdated drying methods that consume too much energy or result in inconsistent product quality. Modern solutions have evolved significantly to address these pain points. For instance, manufacturers like Nasan have introduced specialized equipment designed to handle specific industrial needs while keeping energy costs manageable.

Understanding how to leverage this technology can change your production line from a cost center into a competitive advantage.

The Role of a Commercial Dryer in Modern Industry

A commercial dryer does more than simply blow hot air over a product. In an industrial setting, it serves as a precision tool for moisture management.

The primary function is to reduce the water content of a material to a specific, predetermined level. This prevents the growth of bacteria and mold in food products. In materials like wood or ceramics, it prevents cracking and warping after production.

Unlike residential units, these machines are built for continuous operation. They must handle large volumes of raw materials day in and day out.

Efficiency is the main driver here. A well-engineered dryer utilizes heat transfer and airflow dynamics to remove moisture without damaging the product. This balance is difficult to achieve but essential for profitability.

Major Types of Drying Technologies

Not all dryers are created equal. The market offers several technologies, each suited for different materials.

Heat Pump Dryers

These are becoming the standard for energy-conscious businesses. A heat pump commercial dryer works by recirculating air and recovering waste heat. Instead of venting hot air outside, the system captures that energy and uses it to heat the incoming air. This can reduce energy consumption by up to 70% compared to traditional electric heaters. They are excellent for drying fruits, vegetables, meat, and seafood because they operate at lower, controlled temperatures.

Microwave Dryers

Speed is the advantage here. Microwave drying penetrates the material, heating the water molecules directly from the inside out. This results in very fast drying times. It is often used for sterilization and drying of herbs, teas, or insect larvae. However, the energy cost can be higher, and it requires careful control to avoid burning the product.

Hot Air Circulation Dryers

This is the traditional method. Large fans blow heated air over the trays of products. While simple and cheaper to install initially, they can be expensive to run if not insulated properly. They are still widely used for simple industrial drying tasks where temperature sensitivity is not the primary concern.

Freeze Dryers (Lyophilization)

For high-value products like pharmaceuticals or premium coffee, freeze drying is the top choice. The product is frozen, and the pressure is lowered to allow the ice to sublime directly into vapor. This preserves the shape and chemical structure perfectly. It is the most expensive method but yields the highest quality.

Step-by-Step: The Industrial Drying Process

Implementing a commercial dryer into your workflow requires a structured approach. Here is what the typical operation looks like.

1. Pre-processing and PreparationBefore the material enters the machine, it must be prepared. For food, this might involve slicing, peeling, or blanching. Uniform size is crucial. If pieces vary in thickness, they will dry at different rates, leading to inconsistency.

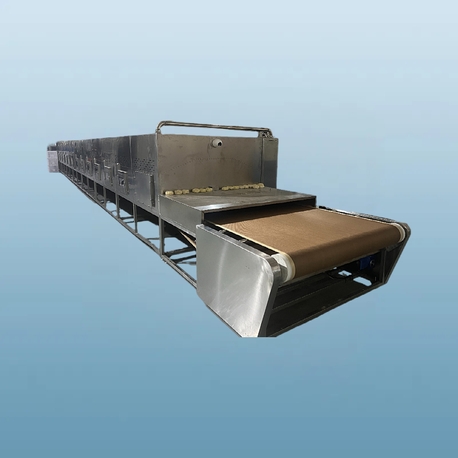

2. Loading the ChamberProper loading ensures airflow. Whether you are using a tray dryer or a conveyor belt system, overcrowding is a common mistake. Air needs to circulate around every surface of the item.

3. Setting ParametersOperators must set the temperature, humidity, and time. Advanced units allow for "staged drying." You might start with a higher temperature to remove surface water and then lower it to slowly draw out internal moisture.

4. The Drying CycleDuring the cycle, sensors monitor the humidity levels inside the chamber. The machine adjusts the air intake and exhaust automatically.

5. Cooling and UnloadingOnce the target moisture content is reached, the product needs to cool down before packaging. Packaging warm products can lead to condensation inside the bag, ruining the effort.

Choosing the Right Commercial Dryer for Your Business

Selecting the right equipment involves more than just looking at the price tag. You must consider the total cost of ownership.

Energy EfficiencyThis is usually the biggest operational cost. An electric heater might be cheap to buy, but a heat pump system often pays for itself within a year or two through electricity savings. Brands like Nasan focus heavily on this aspect, creating closed-loop systems that minimize energy waste.

Material CharacteristicsWhat are you drying? Sensitive materials like flowers or probiotics die at high temperatures. You need a machine that offers precise low-temperature control. Heavy industrial materials like sludge might require high heat and high airflow velocity.

Capacity NeedsDo you need to dry 100kg per batch or 10 tons per day? Sizing your commercial dryer correctly is vital. Undersizing leads to bottlenecks, while oversizing wastes energy heating empty space.

Installation SpaceIndustrial dryers can be massive. Measure your facility's floor space and ceiling height. Also, consider the ventilation requirements. Some dryers need to vent moist air outside, requiring ductwork.

Solutions for Common Drying Challenges

Even with good equipment, operators face challenges. Here is how to solve them.

Uneven DryingIf some trays are wet while others are crispy, your airflow is poor. Check for blocked vents or overloaded trays. Rotating the trays halfway through the cycle can also help.

Case HardeningThis happens when the surface dries too fast, forming a crust that traps moisture inside. This is common in fruits and meats. The solution is to lower the initial temperature and increase humidity slightly at the start to keep the pores open.

Long Drying TimesIf drying takes longer than expected, check the ambient humidity. If the intake air is already humid and you aren't using a closed-loop system, the dryer has to work harder. Regular maintenance of the dehumidification system is required.

High Energy BillsInspect the insulation. Heat loss through the walls of the drying chamber is money flying away. Ensure the door seals are tight.

Applications Across Different Sectors

The versatility of a commercial dryer makes it useful in diverse fields.

Food IndustryFrom making beef jerky to drying mango slices, this is the largest sector. Hygiene is the priority here. The equipment must be made of food-grade stainless steel and be easy to clean.

AgricultureFarmers use dryers to preserve grains and seeds. Moisture control prevents germination and fungal attacks during storage. It allows farmers to harvest earlier and dry the crop mechanically rather than waiting for unpredictable weather.

Wood and TimberFreshly cut wood contains a lot of water. Kiln drying is necessary to stabilize the lumber before it can be used for furniture or construction.

Waste ManagementIndustrial sludge contains water that makes it heavy and expensive to transport. Drying the sludge reduces its weight and volume, significantly cutting disposal costs.

Maintenance for Long-Term Performance

To keep your commercial dryer running efficiently for years, a maintenance schedule is non-negotiable.

Clean the FiltersAir filters get clogged with dust and debris. A clogged filter restricts airflow, forcing the fans to work harder and reducing drying efficiency.

Check the SensorsTemperature and humidity sensors can drift over time. Calibrate them regularly to ensure the machine is reading the environment accurately.

Inspect Door SealsRubber gaskets can crack or wear out. Leaky seals disrupt the internal climate of the drying chamber.

Fan and Motor InspectionListen for unusual noises. Lubricate bearings as per the manufacturer's manual. A failed fan motor stops production immediately.

Why Quality Equipment Matters

Investing in a high-quality machine ensures consistency. When your clients open a package of your product, they expect it to look and taste the same every time.

Cheap dryers often suffer from "hot spots" and "cold spots." This leads to product waste. High-end machines utilize sophisticated airflow designs to ensure uniform distribution of heat.

Furthermore, safety is a concern. Industrial dryers operate at high currents and temperatures. Reliable equipment comes with safety features like overheating protection and emergency stops.

Companies that prioritize R&D, such as Nasan, often integrate smart controls. These allow you to monitor the drying process remotely via a phone or computer, giving business owners peace of mind even when they are not on the factory floor.

The right commercial dryer is a strategic asset. It dictates the speed of your production, the cost of your utilities, and the quality of your final product. By understanding the different technologies available—from heat pumps to microwave systems—you can make an informed decision that suits your specific industry.

Don't overlook the importance of energy efficiency and proper sizing. As energy costs rise, the efficiency of your drying room will directly impact your bottom line.

Whether you are preserving food or processing industrial materials, choosing a reliable partner is key. Manufacturers like Nasan continue to innovate in this space, offering solutions that balance performance with sustainability. Take the time to evaluate your needs, maintain your equipment, and your drying operations will run smoothly for years to come.

Frequently Asked Questions

Q1: What is the most energy-efficient type of commercial dryer?

A1: Generally, heat pump dryers are considered the most energy-efficient. They operate on a closed-loop system that captures and recycles waste heat rather than venting it outside. This can save between 50% to 70% on electricity costs compared to traditional electric heating elements.

Q2: How do I determine the right size dryer for my business?

A2: You need to calculate your daily throughput. Determine the weight of the raw material you need to process per day and the percentage of water that needs to be removed. Manufacturers usually rate their machines by batch capacity (e.g., 500kg per batch). It is often better to buy a slightly larger unit than you currently need to accommodate future growth.

Q3: Can a commercial dryer be used for different types of products?

A3: Yes, most modern dryers are versatile. However, you must adjust the drying parameters (temperature, humidity, and airflow) for each product. For example, herbs require low temperatures to retain color, while meat requires different settings for safety. Programmable logic controllers (PLCs) allow you to save different "recipes" for different products.

Q4: How long does a typical drying cycle take?

A4: There is no single answer as it depends heavily on the material, its thickness, and the water content. Leafy herbs might dry in 4-6 hours, while thick fruit slices or meats could take 12-20 hours. Dense hardwoods can take days or weeks. Testing small batches is the best way to establish a baseline.

Q5: What maintenance is required for a commercial dryer?

A5: Routine maintenance includes cleaning air filters and condenser coils to maintain airflow and heat exchange efficiency. You should also regularly inspect door seals for leaks, check fan motors for noise, and calibrate temperature and humidity sensors to ensure accuracy.