In the world of food processing, garlic is a staple ingredient known for its pungent flavor and health benefits. However, preserving garlic efficiently requires specialized equipment, and that's where a garlic dehydrator comes into play. This article delves into the industrial side of garlic drying, exploring key aspects such as industrial garlic dryer systems, the functionality of a garlic drying machine, factors influencing industrial garlic dryer price, and reputable garlic drying equipment manufacturers. Whether you're a small-scale farmer or a large processing plant, understanding these elements can help you make informed decisions. We'll also cover common problems faced during operation and provide practical solutions. By the end, you'll have a clear picture of how to optimize your garlic drying process for maximum efficiency and quality.

What is a Garlic Dehydrator?

A garlic dehydrator is a device designed to remove moisture from garlic cloves, extending their shelf life while preserving nutritional value and flavor. Unlike sun drying, which is time-consuming and weather-dependent, a garlic dehydrator uses controlled heat and airflow to achieve consistent results. These units range from small household models to large-scale industrial garlic dryer systems used in commercial settings. The primary goal is to reduce the water content to below 10%, preventing microbial growth and spoilage. Modern garlic drying machine variants incorporate advanced features like temperature control and automated timers, making them essential for producing garlic powder, flakes, or whole dried garlic. As demand for processed garlic grows, investing in a reliable garlic dehydrator can significantly boost productivity and product quality.

Key benefits of using a garlic dehydrator include faster drying times, uniform output, and better hygiene compared to traditional methods. For industrial applications, an industrial garlic dryer often integrates with other processing lines, allowing for continuous operation. When selecting equipment, it's crucial to consider factors such as capacity, energy efficiency, and the reputation of garlic drying equipment manufacturers. In the following sections, we'll explore these aspects in detail, including how industrial garlic dryer price varies based on specifications.

Types of Garlic Drying Equipment: From Small-Scale to Industrial

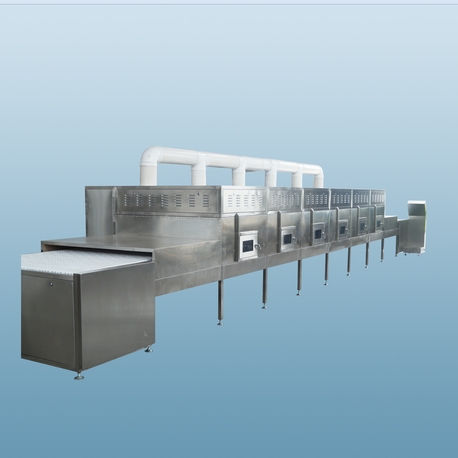

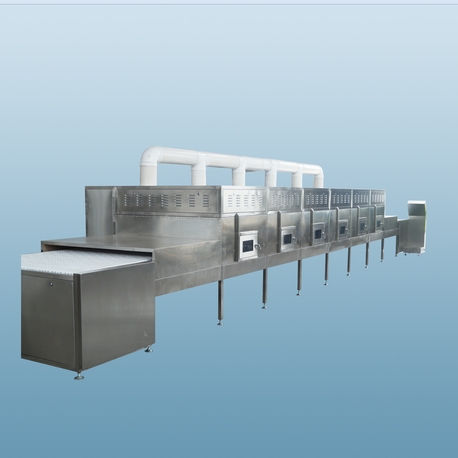

Garlic drying equipment comes in various forms, catering to different needs. At the basic level, a simple garlic dehydrator might be a cabinet-style unit suitable for home use or small businesses. These are often affordable and easy to operate but lack the capacity for high-volume production. On the other end of the spectrum, an industrial garlic dryer is built for heavy-duty use, featuring larger chambers, conveyor belts, and integrated control systems. Common types include tray dryers, tunnel dryers, and fluidized bed dryers, each offering unique advantages.

A garlic drying machine designed for industrial use typically employs forced air or vacuum technology to speed up the process. For instance, tunnel dryers are popular among garlic drying equipment manufacturers for their scalability, allowing processors to handle tons of garlic per day. Another variant is the continuous belt dryer, which ensures even drying by moving garlic through multiple temperature zones. When evaluating options, it's important to assess your throughput requirements, as this directly impacts the industrial garlic dryer price. Small-scale models might cost a few thousand dollars, while advanced industrial garlic dryer systems can run into six figures. Understanding these differences helps in choosing the right equipment for your operation, whether you're upgrading an existing setup or starting from scratch.

Key Features of an Industrial Garlic Dryer

An industrial garlic dryer stands out due to its robust construction and advanced features. Unlike basic dehydrators, these systems are engineered for efficiency and durability. Key characteristics include high-capacity drying chambers, often made from stainless steel to resist corrosion and meet food safety standards. Temperature control is precise, with ranges typically between 40°C and 70°C to preserve garlic's active compounds like allicin. Many models also feature humidity sensors and programmable logic controllers (PLCs) for automation, reducing labor costs.

Energy efficiency is another critical aspect, as drying can be energy-intensive. Leading garlic drying equipment manufacturers incorporate heat recovery systems or solar-assisted options to lower operational expenses. For example, some industrial garlic dryer units use indirect heating to minimize energy loss. Additionally, safety features such as overload protection and fire suppression systems are standard in high-end models. When comparing industrial garlic dryer price, these features can add to the cost but offer long-term savings through reduced downtime and higher output. It's advisable to request demonstrations from garlic drying equipment manufacturers to see these features in action, ensuring they align with your production goals.

How a Garlic Drying Machine Works

Understanding the mechanics of a garlic drying machine is essential for optimal use. The process begins with preparation: garlic cloves are peeled, sliced, or left whole, depending on the desired end product. They are then loaded into the drying chamber of the garlic dehydrator. In an industrial garlic dryer, this might involve automated feeding systems to maintain consistency. The machine generates heated air, which is circulated evenly across the garlic surfaces using fans or blowers. This airflow removes moisture gradually, preventing case hardening where the exterior dries too quickly, trapping moisture inside.

The drying cycle duration varies based on factors like garlic size and initial moisture content, but an efficient garlic drying machine can complete the process in 6 to 12 hours for industrial batches. Advanced units may use multi-stage drying, starting with higher temperatures to kill microbes and finishing with lower heat to preserve quality. Monitoring systems track parameters like weight loss and humidity, adjusting settings automatically. This precision is why many garlic drying equipment manufacturers emphasize their machines' smart controls. By mastering these operations, users can avoid common pitfalls, such as uneven drying or nutrient loss, which we'll address later in the common problems section.

Factors Influencing Industrial Garlic Dryer Price

The industrial garlic dryer price can vary widely, from $10,000 for basic models to over $100,000 for custom-built systems. Several factors drive this range. First, capacity is a major determinant; larger units that process several tons per day command higher prices. For instance, a small garlic drying machine with a capacity of 100 kg per batch might be affordable for startups, while an industrial garlic dryer handling 1,000 kg per hour requires a significant investment.

Second, technology level affects cost. Basic garlic dehydrator models with manual controls are cheaper, but automated systems with PLCs and IoT connectivity add to the industrial garlic dryer price. Energy efficiency features, such as heat pumps or solar panels, can also increase upfront costs but reduce long-term expenses. Third, materials matter: stainless steel construction, which is essential for food-grade applications, is more expensive than carbon steel. Additionally, brand reputation plays a role; established garlic drying equipment manufacturers often charge premium prices for reliability and after-sales support. Other factors include customization options, installation requirements, and geographic location, as shipping large equipment can add costs. When budgeting, it's wise to obtain quotes from multiple garlic drying equipment manufacturers and consider total cost of ownership, not just the initial industrial garlic dryer price.

Top Garlic Drying Equipment Manufacturers

Choosing the right manufacturer is crucial for acquiring a high-quality garlic dehydrator. Several garlic drying equipment manufacturers have built strong reputations in the industry. Companies like GEA Group, Buhler, and OKAWARA are known for their robust industrial garlic dryer systems, offering global support and innovative designs. These manufacturers often provide comprehensive services, from consulting to installation and maintenance.

When selecting among garlic drying equipment manufacturers, consider their experience in food processing equipment. For example, some specialize in modular garlic drying machine units that can be scaled as your business grows. It's also important to review customer testimonials and case studies to gauge reliability. Many manufacturers offer customized solutions, which can affect the industrial garlic dryer price but ensure the equipment meets specific needs, such as organic certification compliance or space constraints. Additionally, look for warranties and spare parts availability to minimize downtime. By partnering with reputable garlic drying equipment manufacturers, you can invest in a garlic dehydrator that delivers consistent performance and longevity.

Common Problems with Garlic Dehydrators and Solutions

Even with advanced equipment, users may encounter issues when operating a garlic dehydrator. One common problem is uneven drying, where some cloves remain moist while others become overly dry. This often stems from improper loading or inadequate airflow in the garlic drying machine. Solution: Ensure even spacing of garlic pieces and regularly clean air vents. For industrial garlic dryer systems, calibrate fans and sensors periodically.

Another issue is discoloration or loss of flavor, which can occur if temperatures are too high. A garlic dehydrator set above 70°C may degrade sensitive compounds. Solution: Follow manufacturer guidelines for temperature settings and pre-test small batches. Energy inefficiency is also a concern, especially with older industrial garlic dryer models, leading to high operational costs. Solution: Upgrade to energy-efficient units or add heat recovery systems offered by leading garlic drying equipment manufacturers.

Mechanical failures, such as belt jams in conveyor-type garlic drying machine units, can cause downtime. Regular maintenance is key: lubricate moving parts and inspect electrical components. Lastly, hygiene problems like mold growth might arise if the garlic dehydrator isn't cleaned properly. Solution: Implement strict sanitation protocols using food-safe cleaners. By addressing these issues proactively, you can maximize the lifespan of your equipment and maintain product quality, making the industrial garlic dryer price a worthwhile investment.

FAQs About Garlic Dehydrators

Q: What is the average lifespan of an industrial garlic dryer?

A: With proper maintenance, an industrial garlic dryer can last 10-15 years. Regular servicing by garlic drying equipment manufacturers can extend this further.

Q: How do I calculate the right capacity for my needs?

A: Consider your daily garlic intake and peak seasons. A garlic drying machine with scalable options from garlic drying equipment manufacturers allows flexibility.

Q: Can a garlic dehydrator handle other products?

A: Yes, many garlic dehydrator models can dry herbs, vegetables, or fruits, but check with manufacturers for compatibility to avoid cross-contamination.

Q: What safety standards should I look for?

A: Ensure the industrial garlic dryer meets local food safety regulations, such as FDA or CE marks, from reputable garlic drying equipment manufacturers.

Q: How does industrial garlic dryer price compare to operating costs?

A: While the initial industrial garlic dryer price might be high, energy-efficient models save on electricity and maintenance, offering better ROI.

In summary, a garlic dehydrator is a vital tool for modern food processing, with industrial garlic dryer systems offering scalability and efficiency. From understanding how a garlic drying machine functions to evaluating industrial garlic dryer price factors and selecting reliable garlic drying equipment manufacturers, this guide covers essential aspects to inform your decision. By being aware of common problems and their solutions, you can ensure smooth operations. As the demand for dried garlic grows, investing in the right equipment will pay dividends in quality and productivity. If you're in the market, reach out to multiple garlic drying equipment manufacturers for quotes and demonstrations to find the best fit for your needs.