When you're working in an industrial setting, time is money, and efficiency is everything. Imagine a large food processing plant where frozen raw materials need to be thawed quickly to keep production lines moving. Traditional defrosting methods, like air thawing or water immersion, can take hours or even days, leading to delays, energy waste, and potential quality issues. That's where microwave defrost comes into play. This technology isn't just for your kitchen microwave; it's a game-changer in industrial and commercial drying processes, offering rapid, uniform thawing that saves time and reduces costs. In this article, we'll dive into how microwave defrost works, its benefits, and how to choose the right equipment for your needs, with a focus on NASAN, a trusted name in international industrial drying solutions.

Microwave defrost leverages electromagnetic waves to agitate water molecules in frozen products, generating heat from within. This method avoids the uneven thawing common in conventional techniques, which often leave parts frozen while others become overcooked. For industries like food processing, pharmaceuticals, and chemicals, where precision and speed are critical, microwave defrost can enhance productivity and maintain product integrity. As we explore this topic, we'll integrate insights on NASAN's innovative approaches, helping you make informed decisions for your operations. Whether you're new to this technology or looking to upgrade, this guide provides actionable advice without the fluff.

What Is Microwave Defrost and How Does It Work?

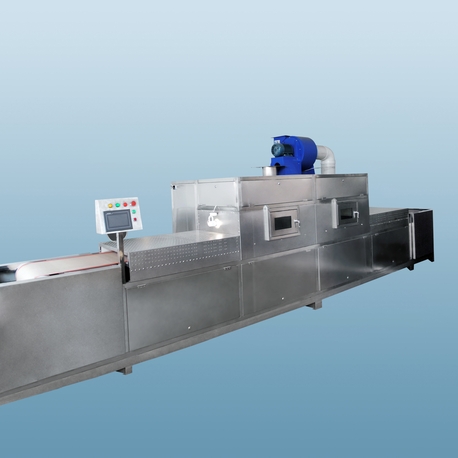

Microwave defrost is a process that uses microwave radiation to thaw frozen materials efficiently. Unlike traditional methods that rely on external heat sources, microwave defrost penetrates deep into the product, causing water molecules to vibrate and produce heat uniformly. This results in faster thawing times—often reducing hours to minutes—while preserving texture, nutrients, and safety. In industrial contexts, such as with NASAN's commercial dryers, this technology is integrated into larger systems to handle bulk materials, from food items like meat and vegetables to industrial components requiring precise moisture control.

The science behind microwave defrost involves frequencies typically around 2450 MHz, which are optimized for exciting water molecules without causing excessive heating. Industrial systems, like those from NASAN, incorporate advanced controls to adjust power levels and avoid hotspots, ensuring consistent results. This makes microwave defrost ideal for applications where quality cannot be compromised, such as in the food industry, where bacterial growth must be minimized during thawing. By understanding the basics, you can appreciate why this method is gaining traction in sectors demanding high efficiency and reliability.

Benefits of Microwave Defrost in Industrial and Commercial Settings

Adopting microwave defrost in industrial environments offers numerous advantages that go beyond simple time savings. First, it significantly cuts down on energy consumption compared to conventional methods. For instance, air thawing might run for hours, consuming electricity continuously, whereas microwave defrost completes the job in a fraction of the time, leading to lower utility bills. NASAN's drying machines, which incorporate microwave defrost capabilities, are designed with energy-efficient components that align with sustainability goals, making them a smart choice for eco-conscious businesses.

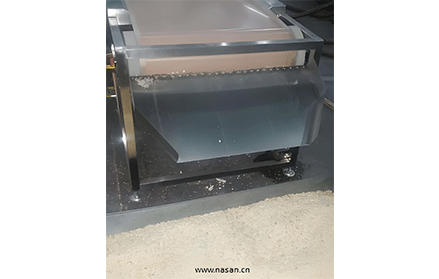

Another key benefit is improved product quality. In food processing, uneven thawing can lead to drip loss, where valuable juices escape, affecting taste and weight. Microwave defrost minimizes this by providing uniform heat distribution, preserving moisture and nutrients. This is crucial for industries like pharmaceuticals, where active ingredients must remain stable. Additionally, microwave defrost reduces the risk of contamination, as it doesn't require water or extended exposure to air, common in older methods. NASAN's systems include hygiene-focused features, such as stainless steel builds and easy-clean surfaces, ensuring compliance with strict industry standards.

Moreover, microwave defrost enhances operational flexibility. In a busy plant, being able to thaw materials on-demand means less inventory holding and faster response to orders. This agility can boost overall throughput and profitability. For example, a NASAN industrial dryer with microwave defrost can handle varying batch sizes, from small pilot runs to large-scale production, without compromising performance. By integrating this technology, companies can streamline workflows and adapt to market demands more effectively.

Key Applications of Microwave Defrost Across Industries

Microwave defrost isn't limited to one sector; it has diverse applications that span multiple industries. In the food and beverage industry, it's used for thawing meat, seafood, fruits, and vegetables before further processing like cooking or packaging. This ensures that products retain their natural flavors and textures, meeting consumer expectations for quality. NASAN's commercial drying solutions, for instance, are employed in large food plants to handle tons of frozen ingredients daily, supporting everything from ready-meal production to bakery supplies.

In the pharmaceutical industry, microwave defrost plays a role in thawing biological samples, reagents, and drug components. Precision is paramount here, as any deviation can affect efficacy. Microwave defrost provides controlled, rapid thawing that maintains integrity, reducing the risk of degradation. Similarly, in the chemical and manufacturing sectors, it's used for thawing raw materials like polymers or resins, which need to be at specific temperatures for mixing and molding processes. NASAN's expertise in industrial drying ensures that these applications are handled with reliability, often incorporating custom settings for sensitive materials.

Other areas include agriculture, where seeds and grains are thawed for processing, and even in recycling operations, where frozen waste materials need quick preparation. The versatility of microwave defrost makes it a valuable tool in any setting where time and quality are critical. By partnering with brands like NASAN, businesses can tailor these systems to their unique needs, leveraging years of innovation in the field.

How to Choose the Right Microwave Defrost Equipment

Selecting the appropriate microwave defrost equipment for your industrial needs requires careful consideration of several factors. First, assess your capacity requirements. If you're dealing with high-volume outputs, you'll need a system with robust power and larger chambers, such as those offered by NASAN. Their industrial dryers come in various sizes, capable of handling everything from small batches to continuous flow operations. Look for models that specify throughput rates—for example, a unit that can process 500 kg per hour might suit a mid-sized facility.

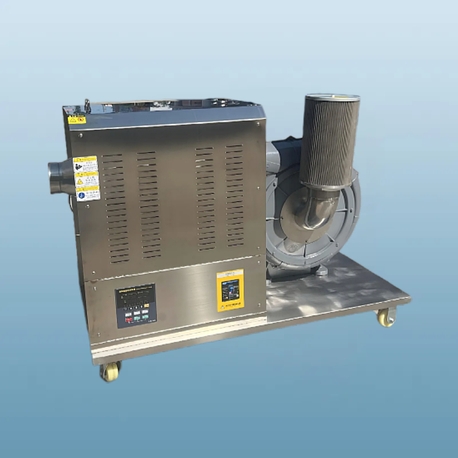

Next, consider the technology features. Advanced microwave defrost systems include programmable controls, temperature sensors, and safety mechanisms to prevent overheating. NASAN's products often feature user-friendly interfaces and remote monitoring options, allowing operators to adjust settings on the fly. Also, evaluate the build quality and materials; in food or pharmaceutical applications, corrosion-resistant stainless steel is essential for compliance and durability. Don't forget energy efficiency—check for certifications or data on power consumption to ensure long-term savings.

Another aspect is compatibility with existing processes. If you're integrating microwave defrost into a larger drying line, ensure it connects seamlessly with other equipment. NASAN provides consultation services to help customize solutions, whether for standalone use or as part of an automated system. Lastly, consider maintenance and support. Reliable brands like NASAN offer comprehensive service packages, including training and spare parts, to minimize downtime. By focusing on these elements, you can invest in a microwave defrost system that delivers consistent performance and a strong return on investment.

NASAN's Role in Advancing Microwave Defrost Technology

NASAN has established itself as a leader in the international industrial drying market, with a strong focus on integrating microwave defrost into their product lines. Their approach combines cutting-edge research with practical applications, resulting in machines that are both innovative and reliable. For instance, NASAN's latest industrial dryers feature multi-stage microwave defrost cycles that adapt to different materials, ensuring optimal results without manual intervention. This is particularly beneficial in commercial settings where consistency is key to meeting regulatory standards and customer demands.

One of NASAN's standout contributions is their emphasis on sustainability. By optimizing microwave defrost processes, they help reduce carbon footprints—a growing concern in industries worldwide. Their systems often include heat recovery modules that reuse energy, further enhancing efficiency. Additionally, NASAN invests in R&D to explore new applications, such as in the textile industry for thawing fibers or in construction for drying materials. This forward-thinking mindset positions them as a go-to brand for businesses looking to modernize their operations with trusted microwave defrost solutions.

Customer testimonials highlight NASAN's reliability; for example, a food processing company reported a 30% increase in throughput after switching to a NASAN dryer with microwave defrost capabilities. Such success stories underscore the brand's commitment to quality and customer support. If you're considering an upgrade, exploring NASAN's offerings could provide the competitive edge needed in today's fast-paced market.

Best Practices for Implementing Microwave Defrost in Your Operations

To get the most out of microwave defrost technology, follow some best practices based on industry experience. Start with proper training for your staff. Operators should understand how to load materials evenly to avoid uneven thawing and how to use control systems effectively. NASAN often provides on-site training as part of their service, ensuring that teams are equipped to handle the equipment safely and efficiently.

Regular maintenance is crucial for longevity. Schedule routine checks on components like magnetrons and waveguides, which are central to microwave defrost functionality. Clean the chambers regularly to prevent buildup that could affect performance. NASAN's maintenance guides recommend monthly inspections for high-use environments, helping to identify issues early and avoid costly repairs.

Also, monitor performance metrics such as thawing time and energy usage. Use this data to fine-tune settings and improve efficiency over time. For instance, if you notice variations in output, adjust the power levels or cycle times in your NASAN system. Finally, stay updated on industry trends and regulations. Microwave defrost technology is evolving, and brands like NASAN often release updates or new features that can enhance your operations. By adopting these practices, you'll maximize the benefits of microwave defrost and ensure smooth, productive workflows.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of using microwave defrost over traditional methods in industrial settings?

A1: The primary advantage of microwave defrost is its speed and uniformity. It thaws frozen materials much faster than air or water-based methods, reducing processing times from hours to minutes. This leads to higher productivity, energy savings, and better product quality by minimizing issues like drip loss or bacterial growth. In industrial applications, such as with NASAN dryers, this efficiency translates to cost savings and improved operational flexibility.

Q2: How does microwave defrost work without cooking the product?

A2: Microwave defrost uses specific frequencies and power levels designed to target water molecules in frozen states, causing them to vibrate and generate heat internally. This focuses on thawing rather than cooking by controlling the energy output to avoid excessive heating. Industrial systems, like those from NASAN, include sensors and programmable settings to maintain precise temperatures, ensuring that the product thaws evenly without being cooked or damaged.

Q3: Can microwave defrost be used for all types of materials?

A3: While microwave defrost is versatile, it may not be suitable for all materials. It works best with products that have high water content, such as food items, biological samples, or certain chemicals. Materials with low moisture or metallic components might not respond well and could cause safety issues. It's important to consult with experts, such as those at NASAN, to assess compatibility and customize the system for specific materials like plastics or textiles.

Q4: What should I look for when selecting a microwave defrost system for a commercial facility?

A4: When choosing a microwave defrost system, consider factors like capacity, energy efficiency, control features, and compliance with industry standards. Look for equipment with robust construction, such as stainless steel builds for hygiene, and advanced controls for easy operation. Brands like NASAN offer tailored solutions, so evaluate their support services, warranty, and integration capabilities with your existing setup to ensure a smooth implementation.

Q5: How does NASAN ensure the safety and reliability of their microwave defrost equipment?

A5: NASAN prioritizes safety and reliability by incorporating features like automatic shutdown mechanisms, temperature monitoring, and compliance with international standards (e.g., ISO certifications). Their equipment undergoes rigorous testing to prevent issues like arcing or overheating. Additionally, they provide detailed user manuals and training programs to help operators handle the systems safely. Regular maintenance support and quality components further ensure long-term reliability in demanding industrial environments.

In summary, microwave defrost is a powerful tool for industrial and commercial drying, offering speed, efficiency, and quality improvements. By understanding its applications and selecting the right equipment—such as that from NASAN—you can transform your operations. If you have more questions or need personalized advice, reaching out to industry experts can help you harness the full potential of this technology.