In industrial food processing and material handling, efficient thawing is a critical step. Traditional methods often create bottlenecks, impacting quality and productivity. Microwave defrost technology offers a modern solution. It uses controlled electromagnetic energy to rapidly and uniformly thaw frozen products. Companies like Nasan have refined this technology for demanding commercial environments. This approach moves beyond the limitations of old techniques, providing consistency and control at scale.

The Technical Principles Behind Industrial Microwave Defrost

Understanding the science of microwave defrost is key to appreciating its industrial value. The process relies on the interaction between microwave energy and polar molecules, primarily water, within a frozen product.

How Micrometers Generate Targeted Heat

Industrial systems generate microwaves at specific frequencies, commonly 915 MHz or 2450 MHz. These waves penetrate the frozen material. Water molecules, being polar, attempt to align themselves with the rapidly oscillating electromagnetic field. This molecular movement creates friction and, consequently, heat directly within the product.

The heat generation starts from the inside out, unlike conventional methods. This core principle allows for faster and more controlled thawing.

Precision Control for Uniform Results

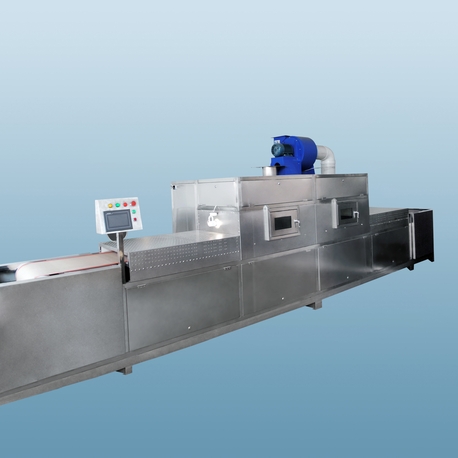

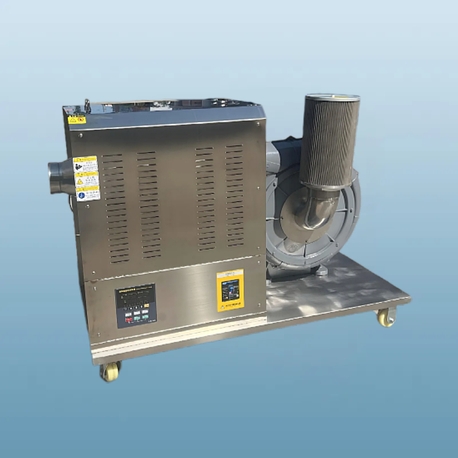

Modern industrial microwave defrost units are not simple ovens. They incorporate sophisticated control systems to manage the main challenge: uneven heating.

Variable Power Output: Systems can adjust power levels in real-time based on product load and temperature feedback.

Conveyor Belt Systems: Products move on a belt through a tunnel, ensuring all portions receive equal exposure to the energy field.

Temperature Monitoring: Infrared sensors and probes provide continuous feedback, allowing the system to automatically stop at the precise target temperature.

This level of control is what makes the technology viable for industrial use. Brands like Nasan integrate these features to ensure repeatable, high-quality outcomes.

Core Advantages of Microwave Defrost in Industrial Operations

Adopting industrial-scale microwave defrost systems delivers significant operational benefits. These advantages directly impact efficiency, product quality, and the bottom line.

Dramatically Increased Speed: Thawing times are reduced from days or hours to minutes. This accelerates production cycles and reduces required freezer storage space for thawing inventory.

Superior Product Quality: Rapid, controlled thawing minimizes the drip loss common in slow methods. It better preserves cellular structure, texture, color, and nutritional value in food products.

Improved Space Efficiency: A compact microwave tunnel replaces large thawing rooms or water tanks. This frees up valuable floor space for other processing activities.

Enhanced Hygiene and Safety: The process is contained and dry, reducing the risk of bacterial cross-contamination associated with water or room thawing. It also minimizes manual handling.

Precision and Consistency: Automated controls ensure every batch reaches the exact same endpoint temperature, eliminating human error and variability.

For businesses processing large volumes, these benefits justify the investment. Nasan's equipment is engineered to maximize these advantages reliably.

Primary Applications for Microwave Defrost Technology

The use of microwave defrost spans several industries where frozen raw materials are a starting point. Its ability to handle bulk quantities with care makes it indispensable.

Meat and Poultry Processing

This is a major application. Plants use microwave systems to thaw blocks of ground meat, whole muscles, poultry portions, and offal. Fast thawing maintains meat color and reduces microbial growth zones, leading to better yields and safer products.

Seafood Industry

Fish fillets, shrimp, and other seafood are highly perishable. Gentle, rapid microwave thawing helps preserve delicate textures and flavors. It prevents the mushiness that can occur with slower methods, ensuring a premium product for retail or further processing.

Bakery and Prepared Foods

Frozen dough, fruits, berries, and vegetable mixes are commonly thawed before mixing or assembly. Microwave systems provide just-in-time thawing, allowing for flexible production scheduling and minimizing ingredient waste.

Pharmaceutical and Chemical Sectors

Beyond food, certain chemical compounds or biological materials require controlled thawing. The precision of industrial microwave systems makes them suitable for these specialized applications, where temperature consistency is critical.

Nasan's technology is adaptable across these diverse fields, offering configurations that meet specific industry standards and throughput requirements.

Comparing Microwave Defrost with Traditional Thawing Methods

To understand the value proposition of microwave defrost, it helps to compare it directly with conventional industrial thawing techniques.

Microwave vs. Air/Chamber Thawing

Air thawing in temperature-controlled rooms is slow, taking 12 to 72 hours. It risks surface spoilage as the outer layer warms first. Microwave thawing completes in minutes with uniform internal heating, offering vastly better speed and quality control.

Microwave vs. Water Immersion Thawing

Water thawing is faster than air but leads to significant nutrient and flavor loss (leaching). It consumes large amounts of water and creates wastewater treatment issues. Microwave is a dry process, preserving product integrity and eliminating water waste.

Microwave vs. Vacuum Thawing

Vacuum thawing uses low pressure to lower the thawing point of water. It is gentle but can be slower and more capital-intensive than microwave for similar capacities. Microwave systems often provide a better balance of speed and equipment footprint for high-volume lines.

Choosing the right system depends on product characteristics and production goals. For operations prioritizing speed, yield, and quality, microwave defrost presents a compelling case. Nasan provides the expertise to help businesses make this comparison based on their specific needs.

Microwave defrost technology has matured into a cornerstone of efficient modern industrial processing. Its ability to deliver speed, consistency, and quality improvement addresses the core challenges of traditional thawing. As industries seek to optimize throughput and reduce waste, this technology becomes increasingly relevant. Implementing a robust system from a trusted provider like Nasan can transform a critical stage in the production line. For businesses looking to gain a competitive edge, investing in advanced microwave defrost equipment is a strategic move toward greater productivity and product excellence.

Frequently Asked Questions About Microwave Defrost

Q1: Does microwave defrost cook the edges of the product?

A1: Not in well-designed industrial systems. Professional microwave defrost equipment uses controlled, lower power settings and even field distribution (often with turntables or stirrers) specifically to thaw without cooking. The goal is to reach a uniform, low temperature (e.g., -3°C to 0°C) throughout.

Q2: What types of products are NOT suitable for microwave defrosting?

A2: Products with uneven composition or metallic components are challenging. Items in sealed metal containers cannot be processed. Very dense, large blocks may also require special programming to ensure the center thaws without overheating the exterior.

Q3: How does microwave defrost impact bacterial growth?

A3: It reduces risk compared to slow methods. By rapidly moving the product through the "danger zone" (4°C to 60°C), it minimizes the time bacteria have to multiply. The dry process also avoids the standing water that can harbor pathogens.

Q4: What is the typical throughput of an industrial microwave defrost system?

A4: Throughput varies greatly by model and product. Systems can be designed to handle from a few hundred kilograms to several tons per hour. Manufacturers like Nasan design solutions based on specific production volume requirements.

Q5: Is industrial microwave defrost equipment energy efficient?

A5: Yes, when considered holistically. While the instantaneous power draw is significant, the extremely short processing time leads to lower total energy consumption per kilogram compared to running thawing rooms for days. Efficiency is also gained from reduced product waste and water usage.