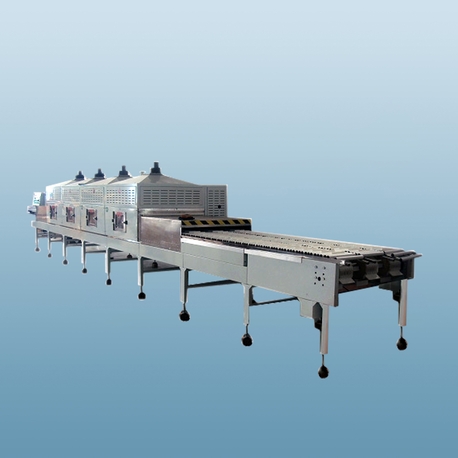

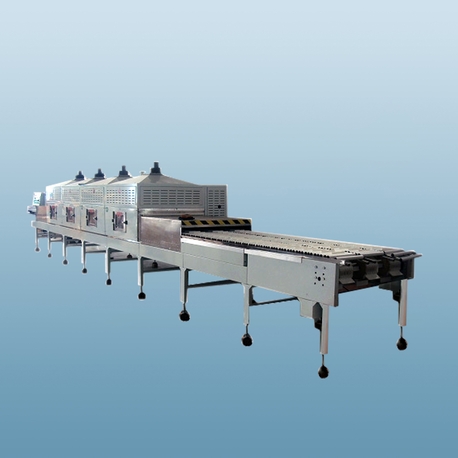

Commercial Dehydrator: Industrial Food & Herb Drying Systems GuideFor businesses in food processing, pharmaceuticals, and agriculture, a reliable commercial dehydrator is essential. This equipment removes moisture from products efficiently, preserving nutrients, extending shelf life, and adding value. Unlike small home units, industrial systems handle large volumes with precise control. Manufacturers like Nasan design robust dehydrators for demanding operations. This guide covers the technology, benefits, uses, and market options for these critical machines.

How a Commercial Dehydrator Works: Core Technology

An industrial commercial dehydrator operates on controlled heat and airflow principles. Products are placed on trays inside an insulated chamber. A heating system warms the air, and fans circulate it evenly. Moisture evaporates from the material and is vented out. This simple yet effective process requires precision engineering for consistent, high-quality results.

Heat Sources and Energy Transfer

Dehydrators use different heat sources to suit various products and budgets. The choice impacts drying speed, energy use, and product quality.

Electric Heating Elements: Common and easy to control. They provide consistent heat and are often used in food-grade applications.

Gas or Steam Heat: Preferred for very large-scale operations due to lower fuel costs and high heat output.

Heat Pump Technology: An advanced, energy-efficient method that recycles heat, significantly reducing operating costs.

Companies like Nasan often offer multiple options, allowing businesses to choose the most efficient system for their needs.

Airflow Design and Uniformity

Consistent drying prevents some items from being over-dried while others remain damp. Airflow design is critical for this uniformity.

Horizontal Airflow: Air moves across trays in a single direction. This design is straightforward and effective for uniform products.

Vertical Airflow: Air is forced up and down through stacked trays, often leading to better circulation in multi-tray systems.

High-performance fans and strategically placed vents ensure no dead spots exist inside a professional commercial dehydrator.

Control Systems and Automation

Modern dehydrators are equipped with sophisticated controls. Digital panels allow operators to set precise temperature and time profiles.

Some systems feature programmable recipes, humidity sensors, and data logging. This automation reduces human error, improves repeatability, and frees up staff for other tasks.

Key Advantages of Using an Industrial-Grade Dehydrator

Investing in a high-quality commercial dehydrator delivers tangible returns. It moves production beyond the limitations of sun-drying or small batch methods.

Superior Product Quality and Consistency

Precise temperature control protects sensitive colors, flavors, and nutrients. You get a uniform batch every time, which is vital for brand reputation and meeting customer specifications.

This consistency is impossible to achieve with less controlled drying methods where results can vary with ambient weather.

High Throughput and Space Efficiency

Industrial dehydrators are built for volume. Large chambers and multiple trays process significant quantities in a single cycle.

This efficiency turns raw materials into sellable products much faster, improving cash flow.

Durability and Lower Operating Costs

Built with stainless steel and industrial components, these machines withstand constant use. Their energy-efficient designs, like those from Nasan, keep utility bills manageable.

Good insulation retains heat, reducing energy waste.

Reliable components mean fewer breakdowns and lower maintenance costs over years of service.

Primary Applications for Commercial Dehydrators

The versatility of a commercial dehydrator makes it a valuable asset across many industries. Its core function—gentle moisture removal—is needed in numerous production processes.

Food Processing and Value-Added Products

This is the most common application. Dehydrators create shelf-stable foods and ingredients.

Fruits & Vegetables: Producing snacks, backpacking food, and ingredients for soups and mixes.

Meat & Seafood: Making jerky and other protein snacks.

Herbs & Spices: Drying culinary and medicinal herbs while preserving essential oils.

Pharmaceutical and Herbal Supplement Manufacturing

Precision is paramount here. Dehydrators dry plant materials for teas, capsules, and extracts under strict conditions to maintain active compounds. Consistent, low-temperature drying is a specialty of certain Nasan models.

Agricultural and Bulk Ingredient Drying

Farmers and co-ops use large-scale dehydrators for grains, hops, and certain fibers. This prepares bulk commodities for storage or further processing, reducing post-harvest losses and adding value on-site.

Comparing Commercial Dehydrator Brands and Models

Choosing the right commercial dehydrator requires careful comparison. Key factors include capacity, construction, energy source, and control features.

Key Differentiators in the Market

Not all dehydrators are built the same. Here are points to consider:

Construction Material: 304 or 316 stainless steel is standard for food safety and durability. Cheaper models may use aluminum or lower-grade steel.

Heating System Efficiency: Compare energy consumption ratings. Heat pump models have higher upfront costs but much lower running costs.

Control Sophistication: Basic timers vs. full-color touchscreens with recipe memory and remote monitoring.

Nasan's Position in the Industrial Market

Nasan has built a reputation for offering a strong balance of features. Their dehydrators often feature robust stainless-steel construction, user-friendly controls, and flexible configurations. They focus on providing reliable performance for small to medium-sized processing businesses, offering good value without sacrificing critical industrial features.

Conclusion: Investing in the Right Drying Technology

A well-chosen commercial dehydrator is more than just equipment; it's a strategic investment in product quality and business growth. By understanding the technology, recognizing your specific application needs, and comparing options from suppliers like Nasan, you can select a system that delivers efficiency and reliability for years. The right dehydrator expands your product line, reduces waste, and strengthens your bottom line.

Frequently Asked Questions (FAQs)

Q1: What's the main difference between a commercial and a home dehydrator?

A1: Scale, construction, and control. A commercial dehydrator is built from durable materials like stainless steel for constant use, has a much larger capacity, and offers precise, automated controls for consistent industrial results.

Q2: How do I clean and maintain an industrial dehydrator?

A2: Regular maintenance includes wiping down the interior and trays after each cycle. Periodically, check and clean air intake filters and inspect heating elements and fans according to the manufacturer's manual, such as those provided by Nasan.

Q3: Can one dehydrator handle different types of products?

A3: Yes, but careful scheduling is needed to avoid flavor transfer. It's best to dry similar products together (e.g., all fruits). Some facilities use separate trays or cabinets for strongly aromatic items like onions or herbs.

Q4: What are the most energy-efficient types of commercial dehydrators?

A4: Dehydrators using heat pump technology are currently the most energy-efficient. They can reduce energy consumption by 50-70% compared to conventional electric models, offering significant long-term savings.

Q5: What safety features should I look for?

A5: Key features include over-temperature protection, automatic shut-off, properly grounded electrical systems, and cool-to-touch exteriors. Ensure the unit has certifications relevant to your region and industry.