In the modern landscape of high-speed food manufacturing, the ability to transition raw materials from a deep-frozen state to a process-ready temperature is a major bottleneck. Conventional methods, such as air thawing or water immersion, often take days and result in significant product degradation. This is where the implementation of an industrial microwave defrost system changes the game. Companies like Nasan have specialized in engineering these high-frequency solutions to ensure that large-scale operations maintain both speed and biological integrity.

The primary challenge for any industrial facility is the balance between speed and quality. When dealing with metric tons of frozen meat, seafood, or fruit, the traditional "wait and see" approach leads to bacterial growth and excessive drip loss. By utilizing microwave defrost technology, processors can reduce thawing times from 48 hours to less than 30 minutes. This shift not only improves the logistics of the factory floor but also ensures a much higher yield by keeping the moisture within the cellular structure of the food.

The Problem with Traditional Thawing Methods

To understand the value of modern equipment, we must first look at the limitations of old-school techniques. Air thawing requires massive tempered rooms that consume vast amounts of energy. Furthermore, the outer surface of the food block stays at a higher temperature for a long duration, which is a massive risk for microbial proliferation.

Water thawing is another alternative, but it is incredibly wasteful. The sheer volume of water required to thaw tons of beef or fish is environmentally unsustainable and expensive. Additionally, water can leach away soluble proteins and nutrients, leaving the final product bland and structurally compromised.

Industrial processing requires a method that penetrates the core of the frozen block simultaneously with the surface. This "volumetric heating" is the hallmark of a professional microwave defrost setup. It bypasses the slow thermal conductivity of ice, reaching the center of a 25kg block in a fraction of the time.

How Microwave Defrost Technology Works at Scale

The science behind this process relies on dielectric heating. Most frozen food products contain water molecules that are polar. When subjected to high-frequency electromagnetic fields, these molecules attempt to align themselves with the rapidly changing field. This molecular friction generates heat directly within the product.

In an industrial environment, these systems typically operate at 915 MHz or 2450 MHz. The 915 MHz frequency is particularly favored for large-scale microwave defrost because it has a longer wavelength. This allows the energy to penetrate deeper into thick blocks of meat or frozen fruit, ensuring that the core reaches the target temperature—usually around -3°C to -1°C—without cooking the edges.

This state is often referred to as "tempering" rather than complete thawing. For most secondary processing tasks, such as slicing, dicing, or grinding, a slightly frozen state is actually preferred. It maintains the structural rigidity of the meat, leading to cleaner cuts and less waste on the production line.

Operational Procedures in a Commercial Setting

Implementing a microwave defrost solution requires a structured workflow to ensure safety and consistency. The process begins with the preparation of the frozen blocks. Most industrial units are designed to handle standard Euro-pallets or specific carton dimensions.

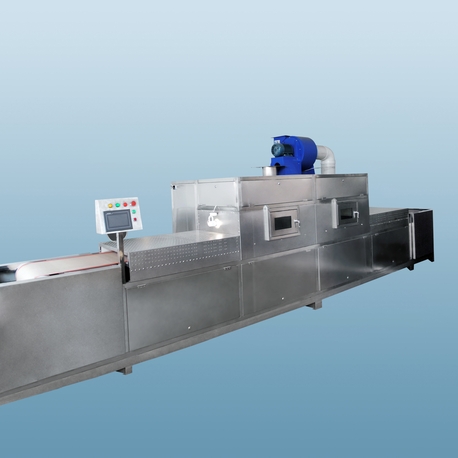

The blocks are placed on a conveyor belt that moves through a shielded tunnel. Inside this tunnel, magnetrons generate the microwave energy. Sophisticated control systems, like those developed by Nasan, monitor the internal temperature and belt speed in real-time. This automation ensures that every block exiting the machine is at the exact temperature required for the next stage of production.

Safety is a paramount concern in these operations. Industrial tunnels are equipped with "microwave traps" or suppressors at the entry and exit points. These components prevent energy leakage, ensuring that the environment remains safe for operators working in the vicinity.

Key Applications in the Meat and Seafood Industries

The meat industry is perhaps the largest benefactor of this technology. Beef, pork, and poultry are often shipped globally in frozen blocks. Processing these for retail—such as making burger patties or chicken nuggets—requires the meat to be tempered quickly. Using a microwave defrost system allows a facility to respond to market demand in real-time rather than planning days in advance.

Seafood processing also relies heavily on precise temperature control. Fish is highly susceptible to texture changes if thawed too slowly. By using controlled electromagnetic waves, processors can bring tuna or salmon blocks to a workable temperature while preserving the delicate fats and proteins that define high-quality seafood.

Even the fruit and vegetable sector has seen a rise in adoption. Frozen fruit pulps or whole berries used in jams and yogurts need to be handled carefully to avoid crushing. A quick microwave defrost cycle softens the product just enough for extraction or mixing without compromising the vibrant color and vitamin content of the fruit.

Minimizing Drip Loss and Improving Yield

From a financial perspective, the most compelling reason to invest in this equipment is the reduction in drip loss. Drip loss refers to the liquid that seeps out of the product during thawing. This liquid is not just water; it contains proteins, vitamins, and minerals. More importantly, for the business owner, this liquid represents lost weight.

In a traditional thawing room, drip loss can account for 3% to 5% of the total product weight. If a plant processes 100 tons of meat a month, that is 5 tons of product literally going down the drain. An efficient microwave defrost cycle can reduce this loss to less than 1%.

By keeping the moisture locked within the fibers, the final product is juicier and more flavorful. This improvement in quality, combined with the weight retention, often allows companies to see a return on their investment within the first year of operation.

Technical Advantages of Nasan Industrial Systems

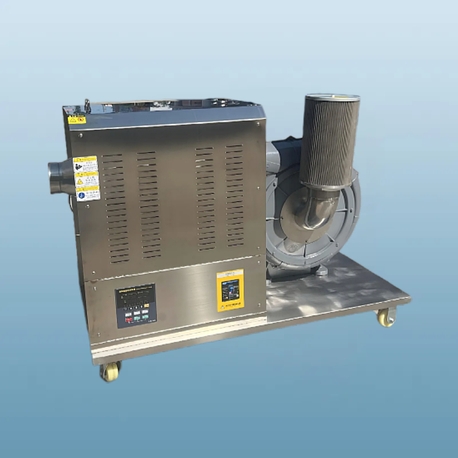

When evaluating suppliers, it is important to look at the robustness of the components. Nasan has built a reputation for using high-durability magnetrons and advanced cooling systems for their power supplies. In a 24/7 manufacturing environment, the reliability of these parts is the difference between a profitable month and a logistical nightmare.

The software interface is another critical factor. Modern systems allow for "recipe-based" operations. If the plant switches from frozen beef blocks to frozen blocks of spinach, the operator simply selects the corresponding preset on the touchscreen. The system automatically adjusts the power levels and conveyor speed to match the dielectric properties of the new material.

Furthermore, modularity is a key feature of the Nasan design philosophy. As a business grows, they can often add more microwave generators to an existing line to increase throughput. This scalability prevents the equipment from becoming obsolete as production quotas rise.

Energy Efficiency and Environmental Impact

There is a common misconception that microwave technology is an energy hog. However, when compared to the total energy required to run a massive refrigerated tempering room for 48 hours, the microwave defrost method is remarkably efficient.

Because the heat is generated directly inside the food, there is no energy wasted heating the surrounding air or the walls of the chamber. The system can be turned on and off instantly. There is no "warm-up" period required for the machine, which means energy is only consumed when there is actually a product on the belt.

From a sustainability standpoint, the elimination of water-based thawing is a huge win. Reducing water consumption and wastewater treatment needs helps food processing plants meet increasingly strict environmental regulations.

Integrating the System into an Existing Production Line

Switching to a microwave defrost workflow usually requires some adjustments to the plant layout. Because the process is so much faster, the "buffer" area previously needed for stacks of thawing meat can be repurposed for more production lines or packaging stations.

The footprint of a microwave tunnel is relatively small compared to a thawing room. This allows for a more linear and logical flow of materials. Raw frozen goods enter at one end, and tempered, process-ready materials emerge at the other, ready for immediate grinding or slicing.

Integration also involves training staff. While the machines are highly automated, understanding the basics of how microwaves interact with different fat and moisture contents is helpful for the quality control team. This ensures they can fine-tune the settings for various batches of raw materials.

Future Trends in Industrial Thawing

We are currently seeing a move toward hybrid systems. These might combine vacuum technology or controlled humidity with microwave energy to achieve even more specific results for niche products. However, for the vast majority of industrial applications, the standard conveyorized microwave tunnel remains the gold standard.

Artificial Intelligence is also beginning to play a role. Sensors can now detect the entry temperature and density of each block as it enters the machine. The AI then calculates the optimal power curve for that specific block, accounting for variations in fat content which can affect how microwaves are absorbed.

As global supply chains become more complex, the ability to process frozen goods quickly and safely is a massive competitive advantage. Facilities that cling to slow, traditional methods will likely find it difficult to compete with the efficiency and quality offered by modern electromagnetic solutions.

The Strategic Value of Advanced Defrosting

The decision to transition to an industrial microwave defrost system is a turning point for any food processing enterprise. It moves the facility away from passive, slow-moving logistics toward a dynamic, just-in-time manufacturing model. By reducing the time from "frozen" to "ready," businesses can significantly lower their inventory overhead and improve their response times to customer orders.

The combination of improved product yield, better hygiene, and significant labor savings makes this technology an essential tool in the modern food engineer's arsenal. With industry leaders like Nasan providing the hardware and support necessary for these complex operations, the barrier to entry is lower than ever.

Ultimately, the goal of any professional processor is to deliver a product that looks and tastes as fresh as the day it was harvested. By utilizing the precision and speed of microwave defrost technology, that goal becomes a daily reality on the factory floor.

Frequently Asked Questions

Q1: Does the microwave defrost process cook the outside of the meat?

A1: No, not when configured correctly. Industrial systems use specific frequencies (like 915 MHz) and power settings designed to "temper" the product to around -2°C. This keeps the product firm and raw, avoiding any graying or "cooking" of the edges.

Q2: How much space does a typical industrial microwave tunnel require?

A2: While it varies by capacity, a standard system is much smaller than a traditional thawing room. Most tunnels are between 5 to 10 meters long and about 2 meters wide, making them easy to integrate into existing production lines.

Q3: Can these systems handle products with different fat contents?

A3: Yes. Fat absorbs microwave energy differently than lean muscle. Modern microwave defrost equipment allows operators to adjust the power and speed settings to account for these differences, ensuring a uniform temperature across different types of meat.

Q4: Is it safe for workers to stand near the machine while it is running?

A4: Absolutely. Industrial units are built with heavy shielding and stainless steel enclosures. They feature sophisticated "chokes" at the entry and exit points that prevent microwave leakage, meeting all international safety standards for electromagnetic emissions.

Q5: What is the maintenance requirement for a Nasan microwave system?

A5: Routine maintenance involves checking the cooling systems for the magnetrons, ensuring the conveyor belt is clean and tensioned, and verifying the integrity of the door seals. Compared to large-scale refrigeration systems, the maintenance is relatively straightforward.

Q6: Can I defrost whole pallets of goods at once?

A6: Most conveyorized systems are designed for individual blocks (20kg-30kg) for maximum uniformity. However, there are batch-style microwave defrost chambers that can accommodate larger crates or even partial pallets, depending on the specific needs of the facility.