In the modern food processing industry, efficiency and sustainability are paramount. A vegetable dehydration machine stands as a cornerstone technology, enabling businesses to preserve nutrients, extend shelf life, and reduce waste. Whether you're in agriculture, food manufacturing, or retail, understanding the ins and outs of an industrial vegetable dehydrator can transform your operations. This article provides a detailed look at these machines, covering everything from key features and selection criteria to top vegetable dehydrator machine manufacturer options and where to buy industrial vegetable dehydrator units. By the end, you'll have a clear roadmap for integrating this essential equipment into your workflow, ensuring you make a smart investment that aligns with your needs.

Vegetable dehydration has evolved from traditional sun-drying methods to advanced mechanical processes that maintain quality and consistency. An industrial vegetable dehydrator is designed for high-capacity operations, handling large volumes of produce with precision. As demand for dried vegetables grows in markets like snacks, soups, and ingredients, knowing how to choose a vegetable dehydration machine becomes critical. This piece will guide you through the benefits, technical aspects, and purchasing strategies, helping you navigate the market with confidence. Let's dive into the world of vegetable dehydration machines and explore how they can elevate your business.

What is an Industrial Vegetable Dehydrator?

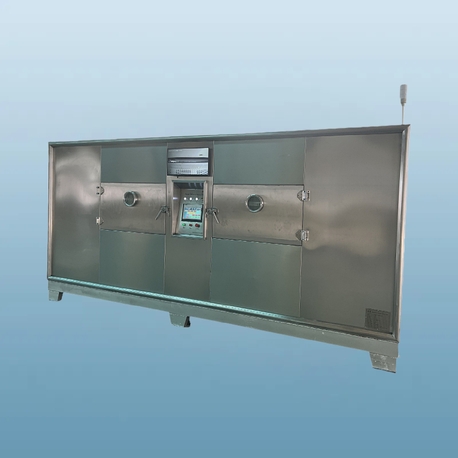

An industrial vegetable dehydrator is a specialized piece of equipment used to remove moisture from vegetables on a large scale, typically in commercial or industrial settings. Unlike smaller home units, these machines are built for durability, high throughput, and energy efficiency. They utilize controlled heat and airflow to evaporate water from vegetables, preserving their nutritional value, flavor, and color. This process inhibits microbial growth, allowing for long-term storage and transportation without refrigeration.

The core components of a vegetable dehydration machine include a heating element, fans for air circulation, trays or conveyor belts for holding produce, and a control system to regulate temperature and time. Industrial models often feature advanced options like programmable settings, humidity sensors, and automated loading systems. This makes them ideal for businesses processing tons of vegetables daily, such as in the frozen food, organic, or export industries. By investing in a reliable industrial vegetable dehydrator, companies can reduce post-harvest losses, meet regulatory standards, and tap into new market opportunities.

Benefits of Using a Vegetable Dehydration Machine

Incorporating a vegetable dehydration machine into your operations offers numerous advantages. First, it significantly extends the shelf life of vegetables—from a few days to several months or even years—reducing food waste and associated costs. This is especially valuable in regions with seasonal produce gluts, where dehydration can stabilize supply chains. Additionally, dehydrated vegetables are lighter and more compact, cutting down on storage and shipping expenses. For businesses looking to expand their product lines, this opens doors to creating value-added items like vegetable powders, snacks, or ready-to-eat meals.

Another key benefit is the preservation of nutrients. Unlike canning or freezing, which can degrade vitamins and minerals, a well-designed industrial vegetable dehydrator retains most of the original nutritional content. This appeals to health-conscious consumers and aligns with trends toward clean labeling. Moreover, these machines enhance food safety by eliminating moisture that fosters bacteria and mold. From an environmental perspective, dehydration reduces the carbon footprint by minimizing the need for refrigeration and transportation. When you buy industrial vegetable dehydrator equipment, you're not just purchasing a tool—you're investing in sustainability and efficiency that pays off in the long run.

Key Features to Look for in a Vegetable Dehydration Machine

When evaluating a vegetable dehydration machine, several features determine its effectiveness and suitability for your needs. Capacity is a primary consideration; industrial models vary in throughput, from a few kilograms to several tons per hour. Assess your production volume to choose a unit that matches your demands without overloading. Energy efficiency is another critical factor, as dehydration can be power-intensive. Look for machines with insulated chambers, heat recovery systems, and low-wattage components to cut operational costs.

The type of dehydration technology also matters. Common methods include tray dryers, tunnel dryers, and belt dryers, each with pros and cons. For instance, belt dryers are ideal for continuous processing, while tray dryers suit batch operations. Controls and automation play a big role too—user-friendly interfaces, programmable cycles, and remote monitoring can streamline workflows. Don't overlook build quality; stainless steel constructions resist corrosion and are easy to clean, meeting hygiene standards. As you learn how to choose a vegetable dehydration machine, prioritize features that align with your specific vegetables (e.g., leafy greens vs. root vegetables) and production goals. Consulting a reputable vegetable dehydrator machine manufacturer can provide insights into customizations that enhance performance.

How to Choose a Vegetable Dehydration Machine: A Step-by-Step Approach

Selecting the right vegetable dehydration machine requires a methodical approach to ensure it meets your operational and financial objectives. Start by assessing your needs: determine the types of vegetables you'll process, your daily volume, and desired output quality. For example, delicate herbs might need lower temperatures than hardy roots. This initial analysis will narrow down the options, whether you're looking for a compact industrial vegetable dehydrator or a large-scale system.

Next, consider the machine's technical specifications. Evaluate the drying time, temperature range, and uniformity of dehydration. Inconsistent drying can lead to spoilage, so opt for models with even air distribution and precise controls. Energy consumption is a major cost driver; compare the efficiency ratings and look for certifications that indicate sustainable design. It's also wise to factor in maintenance requirements—easy-to-clean parts and accessible service points reduce downtime. When pondering how to choose a vegetable dehydration machine, don't forget to review safety features like overload protection and emergency stops.

Budget is a key element, but think beyond the initial purchase price. Calculate the total cost of ownership, including installation, utilities, and ongoing maintenance. Reading reviews and seeking recommendations can highlight reliable models. Ultimately, engaging with a trusted vegetable dehydrator machine manufacturer for a demo or trial can provide hands-on experience. This step-by-step process will guide you to a decision that balances performance, cost, and longevity, making it easier to buy industrial vegetable dehydrator units that deliver value.

Top Vegetable Dehydrator Machine Manufacturers in the Market

Identifying a reliable vegetable dehydrator machine manufacturer is crucial for quality and support. Several companies stand out in the industry, known for their innovation, durability, and customer service. For instance, manufacturers like ABC Food Tech and XYZ Industrial Systems offer a range of industrial vegetable dehydrator models with advanced features such as IoT integration and energy-efficient designs. These brands often provide comprehensive warranties and technical support, ensuring smooth operation from day one.

Another notable manufacturer is GreenDehydrate Inc., which specializes in eco-friendly dehydration solutions. Their machines emphasize reduced carbon emissions and water usage, appealing to sustainability-focused businesses. When selecting a manufacturer, consider their experience, client testimonials, and compliance with international standards like ISO or FDA regulations. It's also beneficial to choose one that offers customization, as your dehydration needs might be unique. By partnering with a top vegetable dehydrator machine manufacturer, you gain access to expertise that can optimize your production line and troubleshoot issues efficiently.

Where to Buy Industrial Vegetable Dehydrator: Tips and Platforms

Once you've decided on the type of vegetable dehydration machine, the next step is to buy industrial vegetable dehydrator equipment from reputable sources. Direct purchases from manufacturers are often the best route, as they provide tailored advice, installation services, and after-sales support. Many manufacturers have online portals or sales representatives who can guide you through the process. Additionally, industry trade shows and exhibitions are excellent venues to see machines in action and negotiate deals.

Online marketplaces and B2B platforms like Alibaba, Thomasnet, or industry-specific sites also list numerous options. However, exercise caution: verify seller ratings, request certifications, and read customer reviews to avoid scams. Leasing or financing options might be available for businesses on a tight budget, spreading the cost over time. Before finalizing a purchase, insist on a performance guarantee and ask for references from existing clients. Whether you buy industrial vegetable dehydrator units new or refurbished, ensure they come with proper documentation and support. This due diligence will help you secure a machine that meets your expectations and integrates seamlessly into your operations.

Maintenance and Care for Your Vegetable Dehydration Machine

Proper maintenance is essential to maximize the lifespan and efficiency of your vegetable dehydration machine. Regular cleaning prevents residue buildup that can affect performance and hygiene. For an industrial vegetable dehydrator, this includes wiping down trays, checking filters, and sanitizing surfaces after each use. Lubricating moving parts, such as fans and conveyors, reduces wear and tear, while inspecting electrical components ensures safety.

Schedule routine inspections by qualified technicians, especially if you have a service agreement with your vegetable dehydrator machine manufacturer. Keep a log of maintenance activities to track issues and predict future needs. Training your staff on proper operation can prevent misuse that leads to breakdowns. By following these practices, you'll maintain consistent output quality and avoid costly repairs, ensuring your investment in a vegetable dehydration machine continues to pay dividends.

A vegetable dehydration machine is more than just equipment—it's a strategic asset that enhances productivity, sustainability, and profitability. From understanding the basics of an industrial vegetable dehydrator to knowing how to choose a vegetable dehydration machine and where to buy industrial vegetable dehydrator units, this guide has covered the essentials. By focusing on your specific needs, researching reputable vegetable dehydrator machine manufacturers, and prioritizing maintenance, you can make an informed decision that drives long-term success. Embrace the power of dehydration to transform your vegetable processing and stay competitive in a dynamic market.

Frequently Asked Questions

Q1: What is the average cost of an industrial vegetable dehydrator?

A1: The cost of an industrial vegetable dehydrator varies widely based on capacity, features, and brand. Basic models may start from $5,000, while high-end systems with automation can exceed $50,000. It's best to get quotes from multiple vegetable dehydrator machine manufacturers to compare prices and consider total ownership costs, including energy and maintenance.

Q2: How long does it take to dehydrate vegetables in an industrial machine?

A2: Dehydration time depends on the vegetable type, thickness, and machine settings. Typically, it ranges from 4 to 12 hours for most vegetables in an industrial vegetable dehydrator. Leafy greens might dry faster than dense roots, and factors like temperature and airflow can adjust the duration.

Q3: Can I dehydrate multiple types of vegetables at once in the same machine?

A3: Yes, many vegetable dehydration machines allow simultaneous dehydration of different vegetables, but it's important to consider similar drying requirements to avoid uneven results. Using separate trays or zones can help, but consult your vegetable dehydrator machine manufacturer for best practices.

Q4: What safety features should I look for when I buy industrial vegetable dehydrator equipment?

A4: Key safety features include overheat protection, automatic shut-off, insulated housings, and emergency stop buttons. Ensure the machine complies with industry standards and has clear instructions. A reliable vegetable dehydrator machine manufacturer will provide safety certifications and training.

Q5: How do I clean and maintain my vegetable dehydration machine?

A5: Regular cleaning involves removing debris from trays, wiping surfaces with food-safe cleaners, and checking for blockages in air vents. Follow the manufacturer's guidelines for lubrication and part replacements. Scheduling professional servicing annually can prevent major issues and extend the machine's life.

Q6: Are there energy-efficient options for vegetable dehydration machines?

A6: Absolutely. Many modern industrial vegetable dehydrators incorporate energy-saving technologies like heat pumps, solar assistance, or recirculation systems. When you how to choose a vegetable dehydration machine, look for energy star ratings or efficiency reports to reduce operational costs and environmental impact.