In the demanding world of industrial and commercial operations, efficiency and reliability aren't just goals—they're the bedrock of profitability. Whether you're running a bustling hotel laundry, a large-scale food processing plant, or a manufacturing facility, the removal of moisture from materials is a critical, often bottleneck, process. This is where the commercial dryer steps in, not just as a machine, but as a pivotal piece of engineering that drives productivity. Far beyond the capabilities of consumer-grade appliances, these workhorses are designed for continuous, heavy-duty cycles, delivering consistent results that directly impact your bottom line. As we delve into the mechanics and applications of these powerful systems, we'll also touch upon how manufacturers like Nasan are integrating advanced technologies to meet modern industrial demands.

What Exactly is a Commercial Dryer?

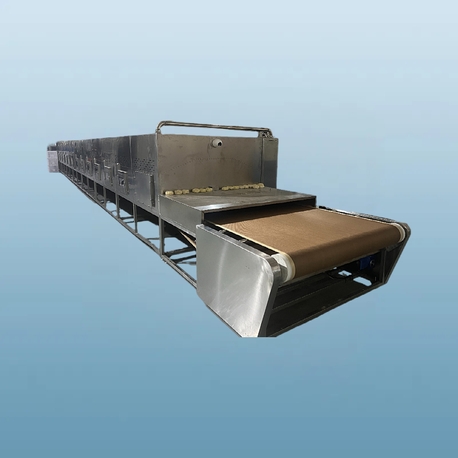

A commercial dryer is an industrial-grade machine engineered to remove moisture or water from large volumes of materials through the application of heat and tumbling action or controlled airflow. Unlike residential dryers, they are built with robust motors, higher capacity drums, and durable stainless-steel components to withstand years of relentless use. Their primary function is to expedite the drying process on a massive scale, ensuring uniformity, hygiene, and material integrity. It's crucial to distinguish these from a commercial dehydrator, which typically uses lower, more controlled temperatures and airflow to slowly remove moisture, often to preserve food. While both remove moisture, a dryer is generally for faster, high-volume moisture removal, whereas a dehydrator is for gentle, prolonged drying for specific outcomes, like making dried fruits or jerky.

Key Advantages of Investing in a Robust Drying System

The decision to implement a high-quality commercial dryer brings a cascade of benefits:

Unmatched Efficiency and Speed: These machines process significantly larger loads in shorter timeframes compared to multiple smaller units. This rapid turnover is essential for operations where time is directly linked to revenue, such as in hotel linens or uniform rental services.

Significant Cost Reduction: While the initial investment is higher, the long-term savings are substantial. Modern commercial dryer units are designed for energy efficiency, using sophisticated moisture sensors to shut off precisely when clothes are dry, eliminating wasted electricity or gas. This also reduces labor costs per pound of material dried.

Superior Durability and Reliability: Constructed for 24/7 operation, these machines minimize downtime. Their robust construction means fewer breakdowns and a longer operational lifespan, providing a better return on investment.

Consistent, High-Quality Results: Industrial dryers offer precise control over temperature and drying cycles. This ensures that every load—whether it's delicate hotel sheets, heavy denim, or industrial parts—comes out uniformly dried without damage, shrinking, or overheating.

How a Commercial Dryer Works: The Process Unveiled

Understanding the operational workflow of a commercial dryer demystifies its efficiency. The process can be broken down into a few key stages:

Loading: The operator loads the pre-washed and spun (or centrifuged) materials into the large drum. Proper loading is essential; overloading can impede airflow and lead to uneven drying, while underloading is inefficient.

Cycle Selection: The operator selects a pre-programmed cycle tailored to the fabric or material type. These settings control temperature, drying time, and drum rotation speed. Advanced models may automatically adjust settings based on moisture sensors.

The Drying Phase: The machine ignites its gas burner or activates its electric heating element. A powerful fan circulates the hot air through the tumbling load, evaporating moisture. The moist air is then vented outside, or in more advanced closed-loop systems, the moisture is condensed and the heat is recycled for extreme efficiency.

Cool-Down and Unloading: Once the internal sensors detect that the load is dry, the heater shuts off, and the drum may continue tumbling with ambient air to cool the contents, reducing wrinkling. The dry, cool load is then ready for unloading and the next stage of processing.

Diverse Industries Relying on Commercial Drying Solutions

The application of commercial dryer technology is vast, spanning numerous sectors:

Hospitality and Laundry Services: This is the most visible application. Hotels, hospitals, and laundromats use massive tumble dryers to process tons of linens, towels, and uniforms daily. Hygiene and speed are paramount.

Food Processing: In this sector, a commercial dryer might be used for surface drying after washing vegetables or certain types of packaging. The related commercial dehydrator is specifically used for creating shelf-stable products like dried herbs, fruits, meats (jerky), and pasta.

Manufacturing and Automotive: These dryers are used to remove moisture or speed the curing process from cleaned metal parts, components, or even after paint or coating applications to prevent rust and ensure adhesion.

Agriculture: Certain crops and grains require precise moisture content for storage and sale. Industrial dryers and commercial dehydrator units are used to achieve this, preventing spoilage and mold.

Choosing the Right Commercial Dryer: A Solution-Oriented Approach

Selecting the appropriate commercial dryer is not a one-size-fits-all endeavor. It requires a careful analysis of your specific needs to find the right solution.

Fuel Type: The choice between natural gas, propane, or electric is often dictated by local utility costs and availability. Gas models generally heat faster and have lower operating costs, while electric models can be simpler to install.

Capacity: Measured in pounds or kilograms per load, capacity should align with your peak operational demands. Investing in a slightly larger capacity than currently needed can accommodate business growth.

Control Systems: Basic manual timers are being phased out by microprocessor-controlled systems. These smart systems offer programmable cycles, diagnostic alerts, and energy-saving features that optimize every load.

Durability and Support: Look for machines with all-stainless-steel cabinets and drums to resist corrosion. Equally important is the manufacturer's reputation for reliability and the availability of responsive service and parts. This is an area where established brands like Nasan have built their reputation, focusing on engineering durable machines backed by strong technical support for industries where downtime is not an option.

A commercial dryer is far more than a simple appliance; it is a strategic investment that enhances operational throughput, slashes ongoing costs, and ensures the quality of your final product. From the linens in a five-star hotel to the components in an automotive plant, the role of efficient drying is indispensable. By understanding its functions, benefits, and the critical factors in selecting the right model, businesses can make an informed decision that pays dividends for years to come. As technology evolves, we can expect even greater integration of smart, energy-recycling features, pushing the boundaries of what these industrial powerhouses can achieve.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a commercial dryer and a commercial dehydrator?

A1: The primary difference lies in the method and purpose. A commercial dryer, like a large tumble dryer, uses high heat and mechanical tumbling to rapidly remove surface moisture from items like linens or clothing. A commercial dehydrator uses lower, more controlled temperatures and steady airflow to slowly and gently remove internal moisture from foods to preserve them, resulting in a completely different end product, such as dried fruit or jerky.

Q2: How can I significantly reduce the energy costs of my commercial dryer?

A2: The most effective way is to invest in a modern model with an automatic moisture sensor. This feature ends the cycle precisely when the load is dry, preventing wasted energy from over-drying. Regular maintenance, including cleaning the lint screen and checking seals for heat loss, is also crucial. Furthermore, opting for a gas-powered model, if feasible, often results in lower operating costs compared to electric.

Q3: My business involves drying delicate food products. Is a standard commercial dryer suitable?

A3: For most food drying applications that require preservation, a standard commercial dryer is not suitable due to its high heat, which can cook rather than dry the food, destroying nutrients and texture. For these tasks, a specialized commercial dehydrator is the correct equipment, as it provides the low, precise temperatures needed for proper dehydration.

Q4: What routine maintenance is essential for a commercial dryer's longevity?

A4: Consistent maintenance is key. Daily tasks include cleaning the lint filter. Weekly or monthly checks should involve inspecting and cleaning the exhaust duct to prevent fire hazards, verifying that thermostats are calibrated correctly, and ensuring the drum is rotating smoothly. An annual professional service is highly recommended to inspect internal components, the heating system, and electrical connections.

Q5: What capacity of commercial dryer do I need for a 100-room hotel?

A5: A precise calculation depends on your occupancy rate, linen types, and laundry workflow. However, a general industry estimate is that a 100-room hotel typically requires a total drying capacity of around 300 to 450 pounds. This is often met by having multiple 75-100 lb capacity dryers to ensure continuous operation even if one unit is down for maintenance. It's best to consult with a professional who can analyze your specific operation.