For factory managers and production engineers, time is money. Traditional drying methods, like hot air or freeze-drying, often create bottlenecks. They are slow, energy-intensive, and can sometimes damage the quality of the product through uneven heating. This is where a commercial microwave system changes the game.

Unlike standard ovens, a commercial microwave offers a rapid, uniform, and energy-efficient solution for removing moisture. Whether you are processing food ingredients, chemicals, or agricultural products, switching to microwave technology can double your throughput. Companies like Nasan have been at the forefront of this shift, helping industries modernize their production lines with advanced microwave machinery.

This article breaks down how these machines work, their specific industrial applications, and why they are superior to conventional drying methods.

Understanding the Commercial Microwave Advantage

Many people hear "microwave" and think of the small box in their kitchen. However, a commercial microwave used in industry is a completely different beast. It is a large-scale, continuous processing machine designed to run 24/7.

The primary difference lies in the heating mechanism. Traditional dryers apply heat to the surface of the material. The heat must then slowly conduct to the center. This often leads to "case hardening," where the outside dries too fast and traps moisture inside.

A commercial microwave uses electromagnetic waves to interact with water molecules directly. This causes the water molecules to vibrate and generate heat through friction. The result is volumetric heating. The material heats from the inside out and the outside in simultaneously. This mechanism allows moisture to escape rapidly without overheating the surface.

Why Speed Matters in Industrial Drying

Speed is the biggest selling point of commercial microwave equipment. Processes that used to take days in a solar drying room or hours in a hot air tunnel can now be finished in minutes.

For example, drying insects like Black Soldier Fly Larvae (BSFL) or mealworms requires precise control. If you dry them too slowly, they rot. If you burn them, you lose nutritional value. A commercial microwave dryer removes the moisture almost instantly, preserving the protein content and the bright color of the product.

This speed also allows for "Just-In-Time" manufacturing. You do not need to stockpile massive amounts of inventory in drying rooms. You can process orders as they come in, reducing storage costs and waste.

Key Applications in the International Market

The versatility of commercial microwave technology allows it to be used across dozens of sectors. Here are the most common areas where this technology is replacing old methods.

Food and Agricultural Products

This is the largest sector for commercial microwave usage. It is used for drying spices, herbs, flowers, and tea leaves. Because the process is fast, it retains the essential oils and aromas that are often lost in hot air dryers.

It is also vital for sterilization. A commercial microwave can dry and sterilize simultaneously. This is essential for powdered spices or grains that need to meet strict export hygiene standards regarding mold and bacteria counts.

Chemical and Pharmaceutical Industries

Powders, granules, and pills often need precise moisture content levels. A commercial microwave offers exact control. Operators can adjust the power output to ensure the product reaches 0.5% moisture content without chemically altering the active ingredients.

Wood and Ceramics

Drying thick wood or ceramic structures is difficult because they crack easily. Since a commercial microwave heats uniformly, it reduces internal stresses. This leads to fewer rejected parts and a higher yield rate for manufacturers.

The Operation Process: How It Works

Operating a modern industrial microwave is safer and easier than operating a massive boiler system. Most systems are conveyor-based (tunnel microwaves).

1. Feeding:The raw material is placed on a food-grade conveyor belt. This can be done manually or via an automated hopper.

2. The Microwave Chamber:The belt carries the material into the heating chamber. Here, magnetrons (the generators of microwave energy) blast the product with waves. Brands like Nasan design these chambers with suppressors to ensure no radiation leaks out, keeping operators safe.

3. Moisture Extraction:As the water turns to steam, strong extraction fans on top of the commercial microwave remove the vapor immediately. This prevents the environment inside the tunnel from becoming too humid.

4. Cooling and Discharge:The product exits the heating zone and passes through a cooling section before being discharged into bins or a packaging line.

Comparing Energy Efficiency

Energy costs are a major concern for any industrial plant. Gas and oil prices fluctuate, making thermal drying expensive. A commercial microwave runs on electricity.

While electricity can be costly per unit, the efficiency of microwave heating offsets the price. You are not heating the air, the walls of the oven, or the conveyor belt. You are only heating the water inside the product.

Data shows that a commercial microwave can be 30% to 50% more energy-efficient than conventional steam or electric resistance dryers. There is no warm-up time required. You turn the machine on, and it is ready to work instantly. When production stops, you turn it off, and consumption drops to zero.

Solutions for Uneven Drying

A common fear regarding microwaves is hot spots. In the past, older machines might burn one part of the product while leaving another cold.

Modern commercial microwave designs have solved this. They utilize "stirrers" or mode mixers inside the chamber to scatter the waves randomly. Additionally, the movement of the conveyor belt ensures that every piece of product passes through different fields of energy intensity.

Advanced PLC control systems allow operators to set specific temperature curves. Sensors monitor the product temperature in real-time. If the product gets too hot, the commercial microwave automatically reduces power. This level of automation is why manufacturers trust companies like Nasan to handle delicate high-value goods.

Maintenance and Longevity

Industrial equipment must be durable. A commercial microwave has fewer moving parts than a rotary drum dryer or a fluidized bed dryer. The main consumables are the magnetrons and the conveyor belt.

Routine maintenance involves keeping the belt clean and checking the cooling system for the magnetrons (usually water-cooled or air-cooled). Keeping the electrical cabinet dust-free is also crucial.

With proper care, the stainless steel structure of a commercial microwave can last for decades. The modular nature of the magnetrons means that if one fails, the machine can often keep running at slightly reduced power until a replacement is swapped in.

Sterilization and Pasteurization

Beyond drying, the commercial microwave is a powerful tool for sterilization. Pests, eggs, mold, and bacteria cannot survive the rapid internal heating.

For the spice trade, this is a massive advantage. You do not need to use chemical fumigants or irradiation (which consumers dislike). You can label your product as "naturally sterilized."

This dual-functionality—drying and sterilizing in one pass—eliminates the need for two separate machines. It saves floor space and reduces capital expenditure.

Choosing the Right Manufacturer

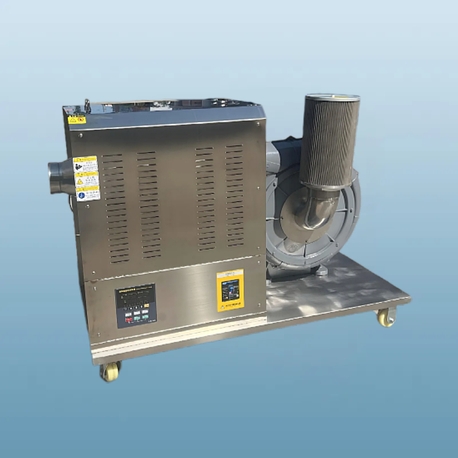

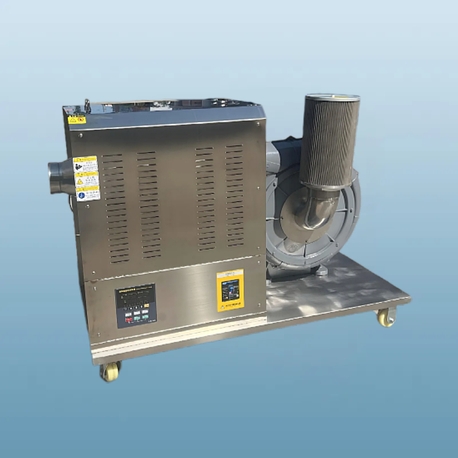

Not all machines are built the same. When selecting a commercial microwave, look for build quality. The chassis should be robust stainless steel (usually SS304). The electronics should be from reputable brands.

Support is also critical. You need a partner who understands your specific material. Nasan often tests materials for clients before they buy, ensuring the frequency and power settings are optimized for that specific product. This consulting phase is vital to avoid buying a machine that is too powerful or too weak for your needs.

Environmental Impact

Sustainability is becoming a requirement, not just an option. A commercial microwave produces zero direct carbon emissions at the factory level. It runs purely on electricity.

If your factory is powered by solar or wind energy, your drying process becomes 100% green. This is a strong marketing point for end-consumers who value eco-friendly production methods. Furthermore, because the process is faster, the total carbon footprint per kilogram of finished product is significantly lower.

Factors Affecting Drying Speed

Several variables dictate how fast a commercial microwave can process your batch.

Initial Moisture Content: A product with 80% water takes longer to dry than one with 30%.Shape and Density: Uniform shapes dry more evenly.Dielectric Properties: Some materials absorb microwave energy better than others. Water absorbs it very well. Fats and oils absorb it differently.Belt Loading: Overloading the belt can shield the bottom layers from the waves. Proper spacing is key.

Safety Features in Modern Machines

Safety is the top priority in heavy industry. A commercial microwave is designed with multiple interlocks.

If a door is opened during operation, the system cuts power instantly. Microwave suppression tunnels at the inlet and outlet prevent waves from escaping the machine. Leakage sensors are often installed to monitor the surrounding area, ensuring it remains well below international safety limits.

Operators do not need to wear special protective gear regarding radiation. The machine is a self-contained unit. The main safety focus is standard thermal safety—handling hot products as they exit the conveyor.

The Future of Industrial Drying

As technology advances, we are seeing the integration of AI and machine learning into commercial microwave control systems. Future machines will predict moisture levels based on input weight and automatically adjust belt speed.

We are also seeing hybrid systems. These combine hot air circulation with microwave energy. The microwave pushes the water to the surface, and the hot air carries it away efficiently. This hybrid approach maximizes the strengths of both technologies.

Whether you are in the food sector, chemical processing, or waste management, the shift toward commercial microwave solutions is undeniable. It offers the efficiency and quality control required to compete in a global market. Brands like Nasan continue to refine these systems, making them more accessible and reliable for businesses of all sizes.

The transition from traditional thermal drying to a commercial microwave system represents a significant leap in industrial efficiency. The ability to dry products rapidly, uniformly, and without compromising quality allows businesses to scale up production and reduce waste.

From preserving the color of dried fruits to ensuring the sterility of pharmaceutical powders, the applications are vast. While the initial investment may be higher than a simple hot air oven, the ROI through energy savings and increased throughput is clear.

If you are looking to upgrade your production line, consider how a commercial microwave can solve your drying bottlenecks. With robust manufacturing partners like Nasan providing tailored solutions, adopting this technology is a smooth process that delivers immediate results.

FAQ: Common Questions About Commercial Microwave Dryers

Q1: Is using a commercial microwave safe for food products?

A1: Yes, it is completely safe. The microwave energy only generates heat; it does not make the food radioactive or leave any chemical residue. It is widely approved by food safety agencies globally for drying and sterilization.

Q2: How much energy can I save compared to a hot air dryer?

A2: Typically, you can save between 30% to 50% in energy costs. A commercial microwave heats the product directly, not the air or the machine structure, making it highly efficient.

Q3: Can a commercial microwave dry metal parts?

A3: No. Microwaves reflect off metal, which can cause arcing and damage the machine (the magnetrons). These machines are designed for non-metallic materials like food, wood, chemicals, and textiles.

Q4: What is the lifespan of the magnetrons?

A4: High-quality industrial magnetrons usually last between 5,000 to 8,000 working hours. They are consumables and are designed to be easily replaced by your maintenance team without stopping the whole line for long periods.

Q5: Does the microwave drying process affect the nutrition of food?

A5: It actually retains nutrition better than traditional methods. Because the processing time is very short and the temperature is controlled, vitamins and heat-sensitive nutrients are preserved much better than in long-duration hot air drying.

Q6: Can Nasan customize the machine size for my factory?

A6: Yes. Most industrial microwave systems are modular. Manufacturers can build the conveyor length and power output (e.g., 10kW, 100kW, or 200kW) to fit your specific production volume and floor space.