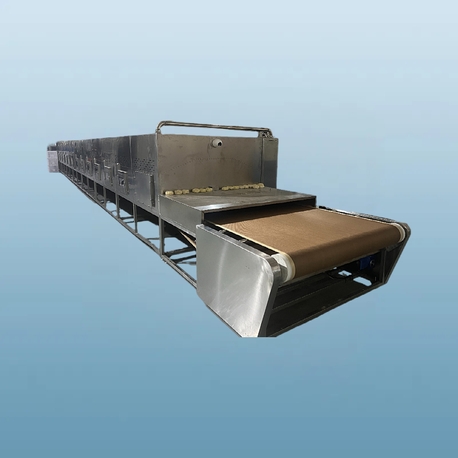

If you're in the market for a new grain dryer, you know it's not a simple purchase. This is a significant investment that sits at the heart of your post-harvest operations. A reliable grain dryer is the difference between selling premium, high-value grain and dealing with the financial losses of spoilage. The right machine doesn't just dry grain; it preserves quality, maximizes efficiency, and protects your bottom line.

But with so many models and technologies available, how do you choose? The decision goes beyond just capacity. It's about integrating a system that works seamlessly with your farm's specific needs, from the types of crops you grow to the energy sources you have available.

Understanding the Core Technology: How a Modern Grain Dryer Works

At its simplest, a grain dryer removes moisture from grain through the application of heat and air. However, the engineering behind modern grain drying is sophisticated. The primary goal is to reduce the moisture content to a safe level for storage—typically around 13-15%, depending on the grain—without damaging the kernels.

The process involves blowing heated air through a column or layer of grain. This air acts as a sponge, absorbing moisture from each kernel and carrying it away. The efficiency of this process depends on the air temperature, humidity, airflow rate, and the time the grain is exposed to the drying air. Unlike simple methods, a commercial-grade grain dryer is designed to do this consistently and uniformly, preventing the dreaded "over-dry/under-dry" pockets that can compromise an entire bin.

Capacity and Throughput: Matching the Dryer to Your Harvest Volume

This is often the first question farmers ask: "How big of a grain dryer do I need?" The answer isn't just about your total acreage; it's about your harvest windows and logistics.

Hourly Capacity: Grain dryers are rated by their bushels-per-hour (BPH) capacity. Remember, this rating is often based on removing a specific number of moisture points (e.g., 10 points from 25% to 15%). If you need to remove more moisture, your effective throughput will be lower.

Batch vs. Continuous Flow: Batch dryers are loaded, dried, cooled, and then unloaded. They are well-suited for smaller, diverse farms. Continuous flow dryers, on the other hand, allow grain to move slowly through the machine, with wet grain entering and dry grain exiting simultaneously. This style is ideal for large-scale operations that need non-stop drying during peak harvest.

Future-Proofing: Consider your farm's growth. Investing in a grain dryer with slightly more capacity than you currently need can be a wise decision, saving you from bottlenecks as you expand.

Energy Efficiency: The Hidden Cost of Drying Grain

Fuel costs are one of the largest ongoing expenses of operating a grain dryer. Therefore, the energy efficiency of the unit is a critical factor in your total cost of ownership.

Heat Source: The most common options are natural gas, propane, and electricity. Natural gas is often the most cost-effective where available, while propane offers more flexibility. The choice will depend heavily on your local utility costs and infrastructure.

Heat Recovery Systems: Advanced grain dryer models incorporate heat recovery systems. These systems capture waste heat from the exhaust and reuse it to pre-warm incoming air, significantly reducing fuel consumption.

Automated Moisture Control: A grain dryer equipped with an in-line moisture sensor is a game-changer. It automatically adjusts the heat and flow rate based on the real-time moisture content of the exiting grain. This prevents over-drying, which wastes fuel and damages grain, and under-drying, which risks spoilage.

Advanced Features to Look for in a Commercial Grain Dryer

Today's grain dryers are more than just metal boxes with a heater. Look for these features that enhance performance, control, and safety.

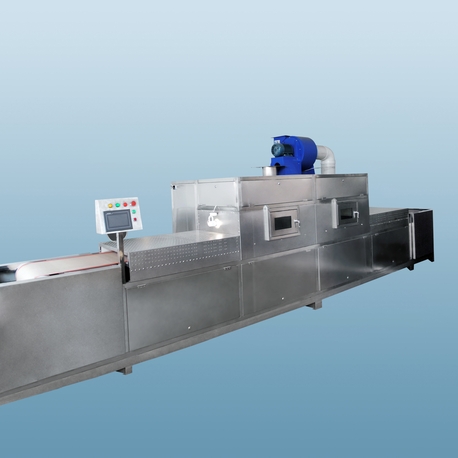

Precision Controls: A user-friendly digital control panel allows you to set precise moisture targets and monitor the entire drying process. Some systems even offer remote monitoring via smartphone apps.

Cross-Flow, Mixed-Flow, and In-Line Designs: The direction of airflow relative to the grain movement impacts drying uniformity. Mixed-flow dryers, for instance, use alternating hot and cool air zones for gentler, more uniform drying, which is excellent for seed grain.

Built-In Safety: Ensure the grain dryer has comprehensive safety features, including high-temperature shut-off switches, flame-out sensors, and clean-out access points to prevent fire hazards from dust accumulation.

The Long-Term View: Installation, Maintenance, and Service Support

The relationship with your grain dryer supplier doesn't end at delivery. Proper installation and reliable service are paramount.

Professional Installation: A poorly installed grain dryer will never perform optimally. It can lead to inefficiencies, higher operating costs, and even safety risks. Always work with qualified technicians for installation.

Preventive Maintenance: Regular maintenance is non-negotiable. This includes cleaning the plenum, inspecting and replacing screens, checking burners, and lubricating moving parts. A well-maintained grain dryer will have a much longer service life and fewer unexpected breakdowns.

Service Network: Before you buy, investigate the manufacturer's or supplier's service network. How quickly can they get a technician to your site during a critical harvest-time failure? Access to readily available parts is equally important.

Choosing the right grain dryer is a complex but crucial decision. By carefully evaluating your capacity needs, prioritizing energy efficiency, and understanding the advanced features and long-term service requirements, you can make an investment that pays for itself in preserved grain quality and operational peace of mind for years to come.

Frequently Asked Questions (FAQ) About Grain Dryers

Q1: What is the average lifespan of a well-maintained commercial grain dryer?

A1: A commercial grain dryer that receives consistent, proper maintenance can easily last between 15 to 25 years. The lifespan heavily depends on the annual usage hours, the types of grain being dried, and the rigor of the preventive maintenance schedule. Components like the burner and fan motors may need servicing or replacement sooner, but the main structure should remain sound for decades.

Q2: Can the same grain dryer be used for different types of grain, like corn, wheat, and soybeans?

A2: Yes, most modern grain dryers are designed to handle multiple grain types. However, the drying parameters will need to be adjusted for each crop. Soybeans, for example, are much more delicate than corn and require lower air temperatures to prevent cracking and splitting. Always consult your grain dryer's manual for specific recommendations and settings for different grains to ensure quality is maintained.

Q3: How significant is the cost of operating a grain dryer, and how can I estimate it?

A3: The operating cost is a major factor and is primarily driven by fuel consumption. To estimate it, you need to know your dryer's fuel type (e.g., propane, natural gas), its average fuel consumption rate (in BTU/hour or gallons/hour), the current price of that fuel, and the total bushels you need to dry. Many suppliers and agricultural extension services offer online calculators that can help you model these costs based on your local energy prices and initial moisture content.

Q4: What are the most common problems that occur with a grain dryer?

A4: The most frequent issues often relate to lack of maintenance. These include clogged screens or perforated floors restricting airflow, dirty burners causing inefficient combustion or shutdowns, and worn-out bearings in the fan or stirring apparatus. Electrical issues with control panels or sensors can also occur. A consistent, scheduled maintenance routine is the best defense against these common problems.

Q5: Is it more cost-effective to use a custom drying service or to invest in my own grain dryer?

A5: This is a fundamental business decision. Using a custom service involves less upfront capital and no maintenance worries, but you pay per bushel and are subject to their availability and potential wait times during a busy harvest. Owning your own grain dryer gives you immediate control over your harvest schedule and grain quality, which can be a significant strategic advantage. The cost-effectiveness depends on your annual volume, the local cost of custom work, and your ability to finance the equipment. For most medium to large-scale farms, owning a grain dryer proves more economical and logistically sound in the long run.