When it comes to industrial drying, curing, and heating processes, the hot air blower is an indispensable piece of equipment. Its efficiency directly impacts production timelines, product quality, and operational costs. Choosing the right one, however, is not a one-size-fits-all decision. The market offers a vast array of industrial hot air blowers, each with different specifications, technologies, and applications. This article breaks down the seven most critical factors you must consider to make an informed investment that will serve your facility reliably for years to come.

Understanding the Core Technology: How a Hot Air Blower Works

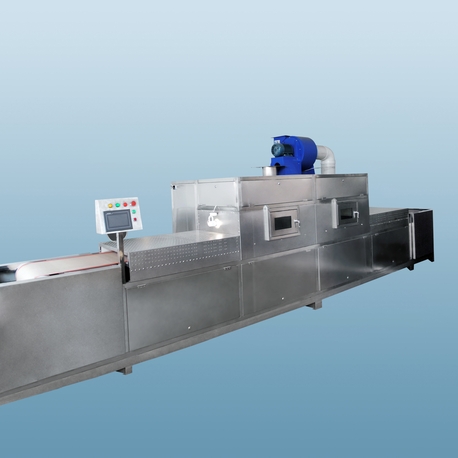

At its heart, an industrial hot air blower is a device that generates a controlled, powerful stream of heated air. The basic principle involves an electrical or gas-powered heating element, a robust fan or blower wheel to move air, and a housing unit that directs the airflow. The air is drawn in, passed over or through the heating element where its temperature is significantly raised, and then forced out through an outlet nozzle. The sophistication lies in the control systems for precise temperature management, the materials used for durability in harsh environments, and the motor technology that ensures consistent airflow volume and pressure. Understanding this fundamental operation is the first step in appreciating the nuances of different models.

Factor 1: Heat Source – Electric vs. Fuel-Fired Systems

The choice of heat source is one of the most fundamental decisions, primarily boiling down to electric and fuel-fired (typically natural gas or propane) systems.

Electric Hot Air Blowers: These units use electric resistance coils to generate heat. They are known for their quick startup, precise temperature control, and clean, contaminant-free air output. This makes them ideal for applications where product purity is paramount, such as in food processing, pharmaceuticals, or electronics manufacturing. Their main drawback is higher operational energy costs in regions with expensive electricity.

Fuel-Fired Hot Air Blowers: These models combust gas to produce heat, which is then transferred to the air via a heat exchanger. They are generally more cost-effective to operate, especially for high-temperature, high-volume applications. They are the go-to choice for large-scale processes like asphalt heating, paint stripping, or industrial space heating. The trade-offs include a more complex installation (requiring venting for combustion gases) and a slightly slower response time.

Factor 2: Airflow and Pressure – Volume vs. Force

Not all hot air blower systems are created equal in terms of their air delivery. This is characterized by two key metrics: airflow (measured in Cubic Meters per Hour or Cubic Feet per Minute) and pressure (measured in Pascals or inches of water column).

High Airflow, Low Pressure: These hot air blowers are designed to move large volumes of air. They are perfect for applications like drying large surface areas (e.g., freshly painted vehicles, textiles, or flooring), convective heating of ovens, and general space heating.

High Pressure, Lower Airflow: These units generate a more focused, forceful stream of air. This is essential for applications where the air must overcome resistance, such as penetrating dense material webs in a paper machine, fluidizing beds in dryers, or through-system applications with long duct runs and high static pressure losses.

Selecting the wrong balance can lead to inefficient operation and failure to complete the task.

Factor 3: Maximum Operating Temperature

The required process temperature is a non-negotiable specification. Industrial hot air blower systems can range from providing mild warmth around 50°C (122°F) to extremely high temperatures exceeding 800°C (1472°F). Electric hot air blowers typically excel in the low to medium-high range, while fuel-fired systems are more efficient for achieving very high temperatures. It is crucial to choose a unit whose maximum temperature comfortably exceeds your process requirement to avoid running the equipment at its absolute limit, which can shorten its lifespan.

Factor 4: Construction Materials and Durability

The operating environment dictates the necessary build quality. A hot air blower used in a clean, climate-controlled room has very different requirements from one in a foundry or a chemical plant.

Standard Units: Often feature powder-coated steel housings and are suitable for general industrial environments.

Corrosion-Resistant Units: Constructed from stainless steel (e.g., 304 or 316 grade) or coated with specialized finishes, these are mandatory for environments with high humidity, salt spray, or exposure to corrosive chemicals.

Explosion-Proof Units: Designed with specific certifications (like ATEX or UL) for use in areas where combustible dust or gases may be present. These units prevent internal sparks from igniting the surrounding atmosphere.

Investing in the correct construction from the outset prevents premature failure and costly downtime.

Factor 5: Control Systems and Automation

Modern industrial processes demand precision and repeatability. The control system of your hot air blower is what delivers this. Basic units may have a simple on/off switch and a manual thermostat. More advanced systems feature Proportional-Integral-Derivative (PID) controllers that maintain temperature within a single degree, digital interfaces for setting complex profiles, and communication ports (e.g., Profibus, Ethernet/IP) for seamless integration into a Plant-Wide SCADA system. For processes involving thermal-sensitive materials, this level of control is not a luxury but a necessity.

Factor 6: Energy Efficiency and Total Cost of Ownership

The initial purchase price is only a fraction of the total cost of owning a hot air blower. Energy consumption over its operational life is the dominant cost. Look for features that enhance efficiency:

Insulated Housings: Minimize heat loss to the environment.

Variable Frequency Drives (VFDs): Allow the fan motor to adjust its speed based on demand, saving significant electricity.

High-Efficiency Motors: Meet or exceed international efficiency classification standards (e.g., IE3, IE4).

Recirculation Capabilities: Some systems can recirculate a portion of the exhaust air, reducing the energy needed to heat fresh incoming air.

A slightly more expensive, but highly efficient hot air blower will often pay for itself in energy savings within a few years.

Factor 7: Maintenance and Service Support

Like any industrial machinery, a hot air blower requires regular maintenance to ensure peak performance and longevity. Consider the accessibility of service points like filters, heating elements, and fan bearings. Does the supplier offer comprehensive technical support, readily available spare parts, and field service? A reliable, long-term partnership with a knowledgeable supplier can be as valuable as the equipment itself, ensuring minimal disruption to your production line.

Selecting the ideal industrial hot air blower is a technical decision that demands a careful analysis of your specific application, environment, and operational goals. By systematically evaluating these seven factors—heat source, airflow and pressure, temperature, construction, controls, efficiency, and service—you can move beyond a simple purchase and make a strategic investment that enhances your production efficiency, ensures product quality, and optimizes your bottom line. The right hot air blower is not just a tool; it's a critical component of your thermal process chain.

Frequently Asked Questions (FAQs)

Q1: What is the typical lifespan of an industrial hot air blower?

A1: The lifespan of an industrial hot air blower varies greatly depending on its build quality, operating environment, and maintenance schedule. A well-maintained standard-duty unit in a clean environment can last 10-15 years. Heavy-duty or corrosion-resistant models in harsh conditions may have a shorter service life of 5-10 years, emphasizing the importance of proper material selection and consistent upkeep.

Q2: Can a hot air blower be used for cooling as well?

A2: Some advanced hot air blower systems are designed with a cooling cycle function. After the heating is turned off, the internal fan continues to run, drawing in ambient air to cool down both the unit itself and the process area. This is a specific feature and is not standard on all models, so it must be specified at the time of purchase if required for your application.

Q3: How often should I perform maintenance on my hot air blower?

A3: Maintenance frequency should follow the manufacturer's guidelines, but it is also condition-dependent. Basic checks, like inspecting air inlets for blockage, should be done weekly. More thorough maintenance, including cleaning heating elements, checking electrical connections, and lubricating bearings (if not sealed), should be performed quarterly or semi-annually. Always consult the unit's manual for a specific schedule.

Q4: What safety features are critical for a hot air blower?

A4: Essential safety features include overtemperature protection (a redundant thermostat that cuts power if the primary control fails), airflow monitoring (to prevent the heater from operating without adequate airflow, which could cause overheating), and properly rated thermal fuses. For fuel-fired units, flame supervision and combustion air proving switches are mandatory.

Q5: My process requires a consistent temperature, but my current blower fluctuates. What could be the issue?

A5: Temperature fluctuations are often a sign of an inadequate control system or a failing component. A basic on/off thermostat has a wide differential, causing swings. Upgrading to a unit with a PID controller can resolve this. Other causes can be a dirty air filter restricting airflow, a failing temperature sensor, or an undersized hot air blower that cannot maintain the setpoint under full process load.