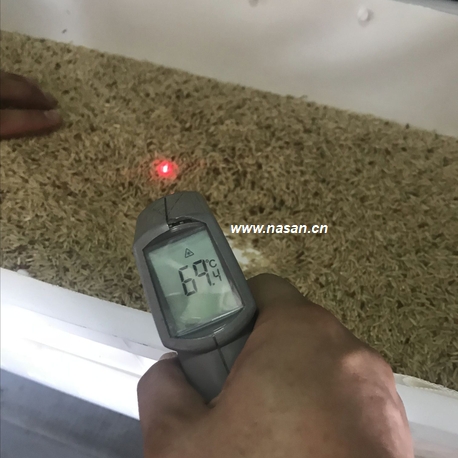

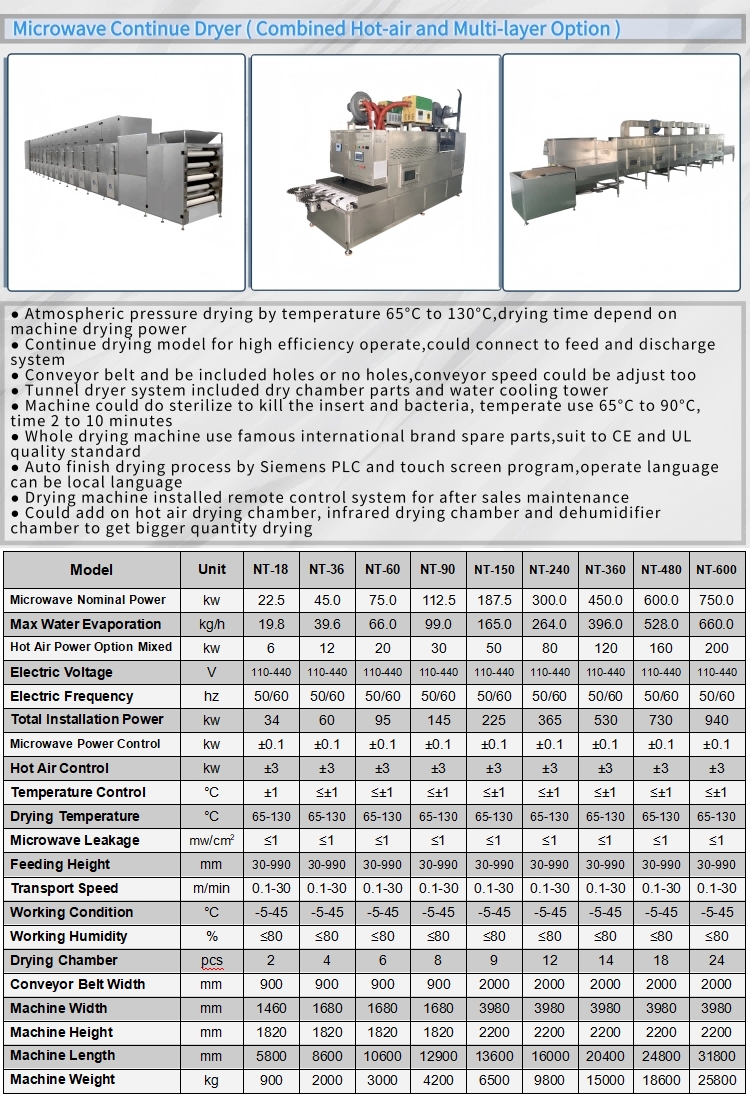

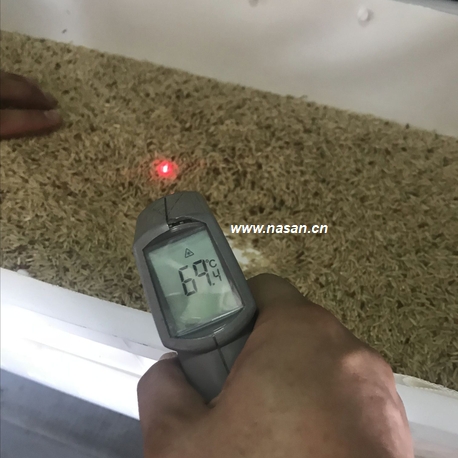

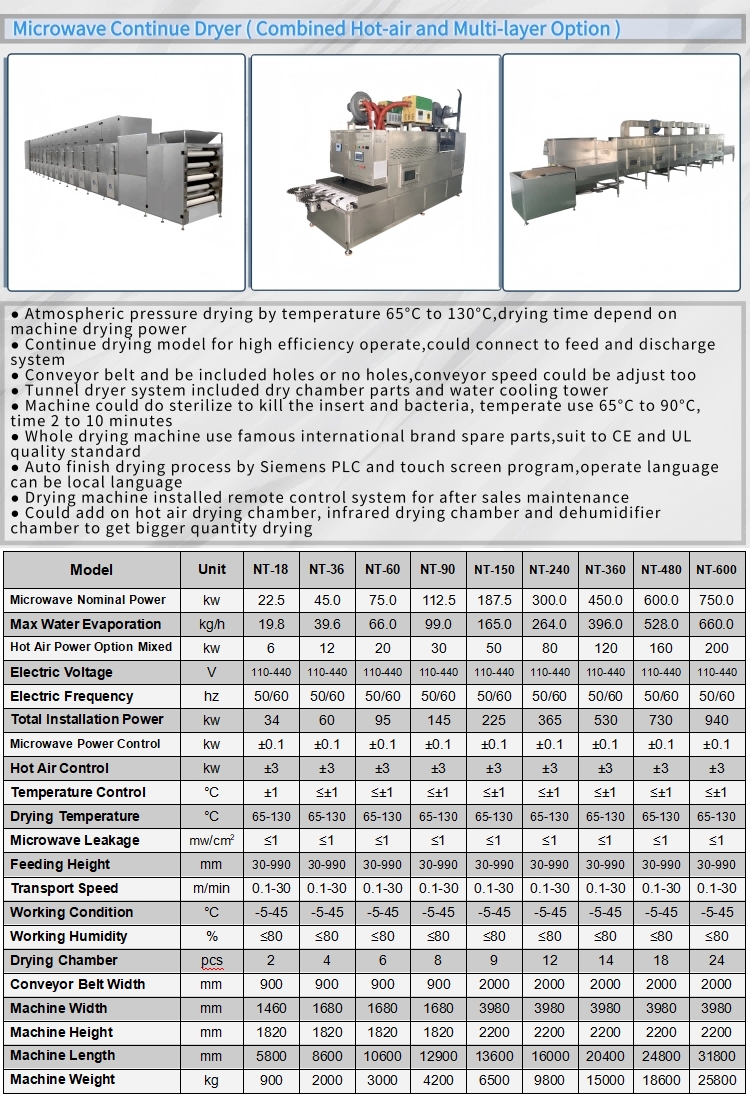

Rice (Oryza sativa) is a global staple food, with post-harvest processing (drying and sterilization) critical to preserving its quality, extending shelf life, and ensuring food safety. Freshly harvested rice has a moisture content of 20-28%—too high for long-term storage (prone to mold growth, insect infestation, and starch degradation). Traditional processing methods (sun drying, hot-air drying, chemical sterilization) have limitations: sun drying is weather-dependent, hot-air drying causes uneven moisture distribution, and chemical sterilization leaves residues. Microwave technology offers a solution: it enables rapid, uniform drying and non-chemical sterilization, preserving rice’s nutritional value, texture, and taste.

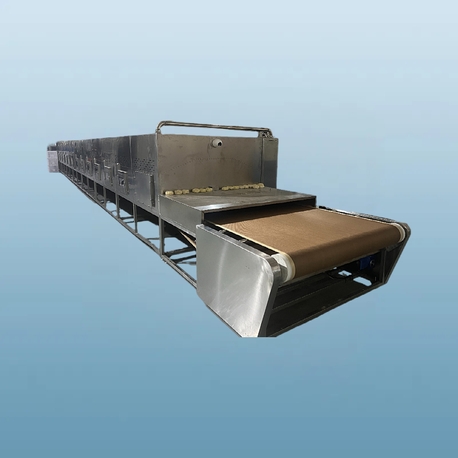

Microwave technology revolutionizes rice post-harvest processing: microwave drying enables fast, uniform moisture reduction (to 12-14%) while preserving texture and nutrients, and microwave sterilization eliminates pathogens/insects without chemicals or quality loss. Together, these processes address the limitations of traditional methods (weather dependence, chemical residues, unevenness) and meet the growing demand for high-quality, safe rice. While upfront equipment costs are higher, the benefits—faster throughput, lower energy use, superior product quality—make microwave processing economically viable for small-scale farmers and large rice mills alike. As food safety standards tighten globally, microwave drying and sterilization will become increasingly integral to rice production.