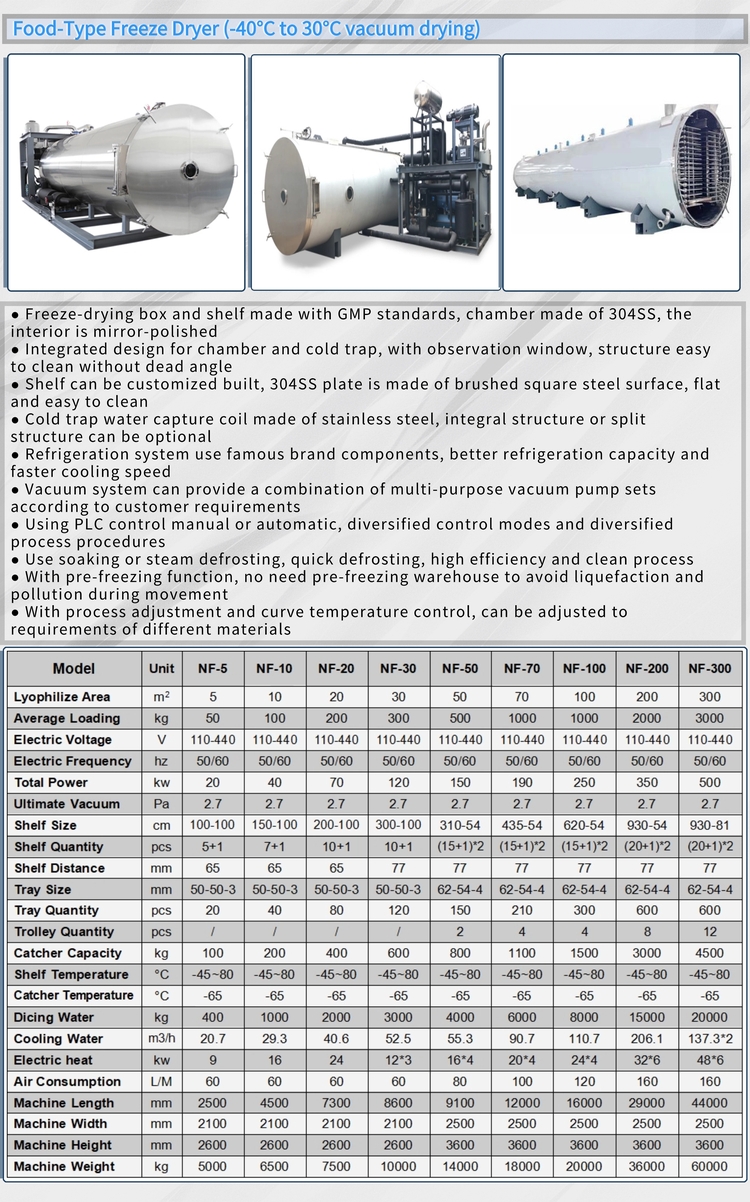

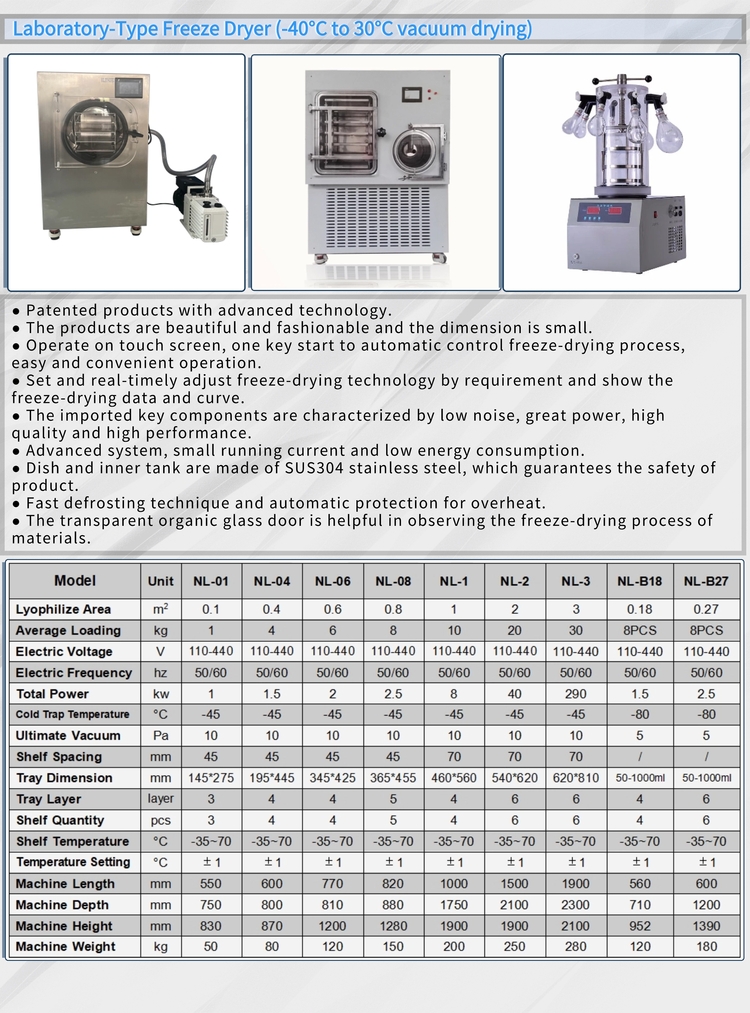

The Vacuum Freeze Food Dryer is a high-end dehydration equipment designed specifically for the food processing industry. It utilizes advanced freeze-drying technology to perfectly preserve the color, aroma, flavor, and nutritional content of food in a low-temperature vacuum environment. The equipment primarily consists of a pre-freezing chamber, a vacuum system, a heating system, and an intelligent control system, meeting food-grade hygiene standards (HACCP certification).

The equipment operates at temperatures ranging from -50°C to 70°C, with a maximum vacuum of less than 10 Pa. Constructed from food-grade 304 stainless steel, it features a high-efficiency -75°C cold trap and a precise temperature control system (±1°C). Its unique multi-stage programmable temperature control technology automatically adjusts drying parameters based on the characteristics of the food, ensuring optimal drying results for a wide range of foods, including fruits, vegetables, meat, and seafood.

This equipment maintains the original shape and pore structure of food, achieving a rehydration rate exceeding 95% and a nutrient retention rate exceeding 90%. It is particularly suitable for the production of high-end ready-to-eat foods, military rations, aerospace food, and health foods. The dried products have a shelf life of 3-5 years, making it an ideal choice for increasing the added value of food products.

1