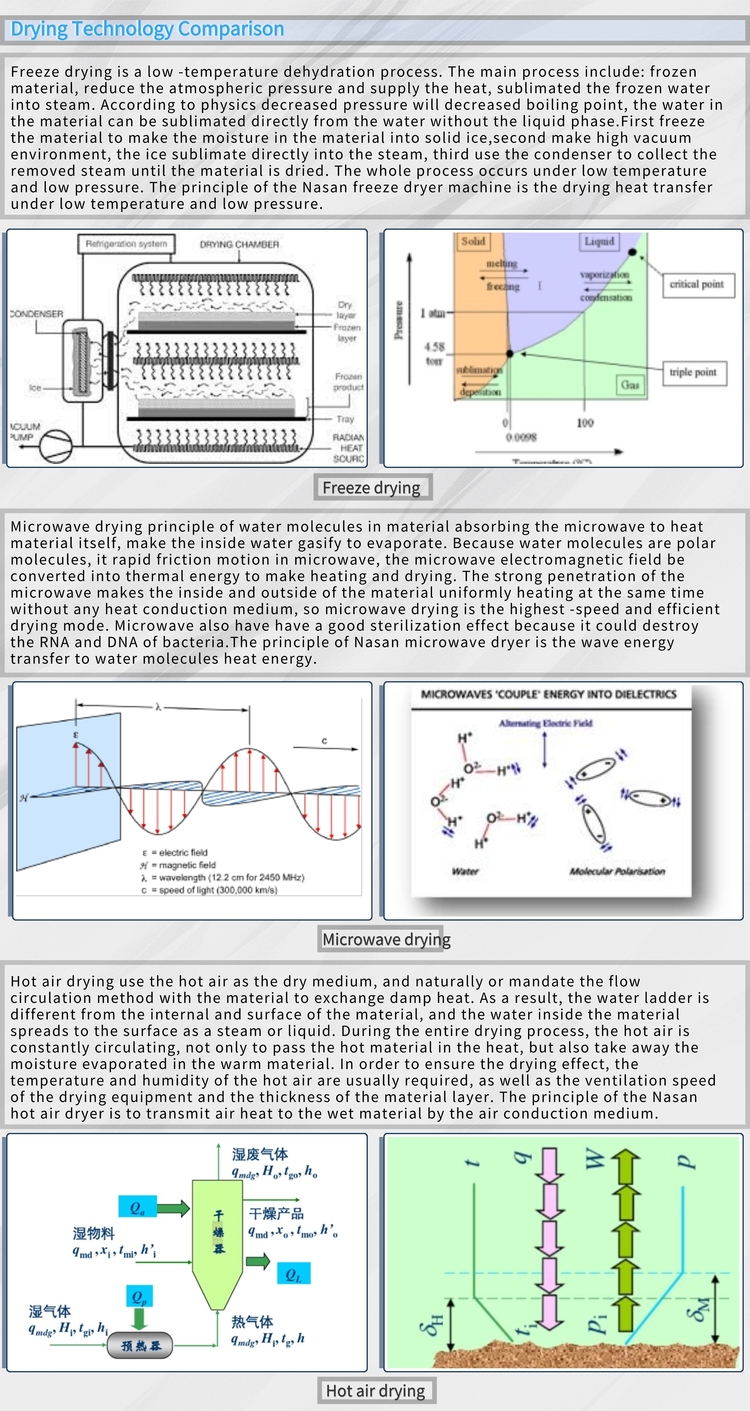

Freeze-drying equipment is a specialized process that preserves material properties through low-temperature dehydration. It primarily utilizes a combination of freezing and vacuum to first freeze the moisture in the material into a solid state. Then, under a vacuum, the ice crystals sublime and are expelled, achieving gentle dehydration. This equipment maximizes the preservation of the material's original form, nutrients, and active ingredients, while avoiding the quality degradation caused by high-temperature drying.

This equipment is particularly suitable for processing heat-sensitive materials such as high-end foods, biological preparations, and precious medicinal herbs, where activity must be preserved. Its unique drying process preserves the material's pore structure, ensuring excellent rehydration. During the dehydration process, the material remains at a low temperature, effectively preventing oxidation, discoloration, and nutrient loss.

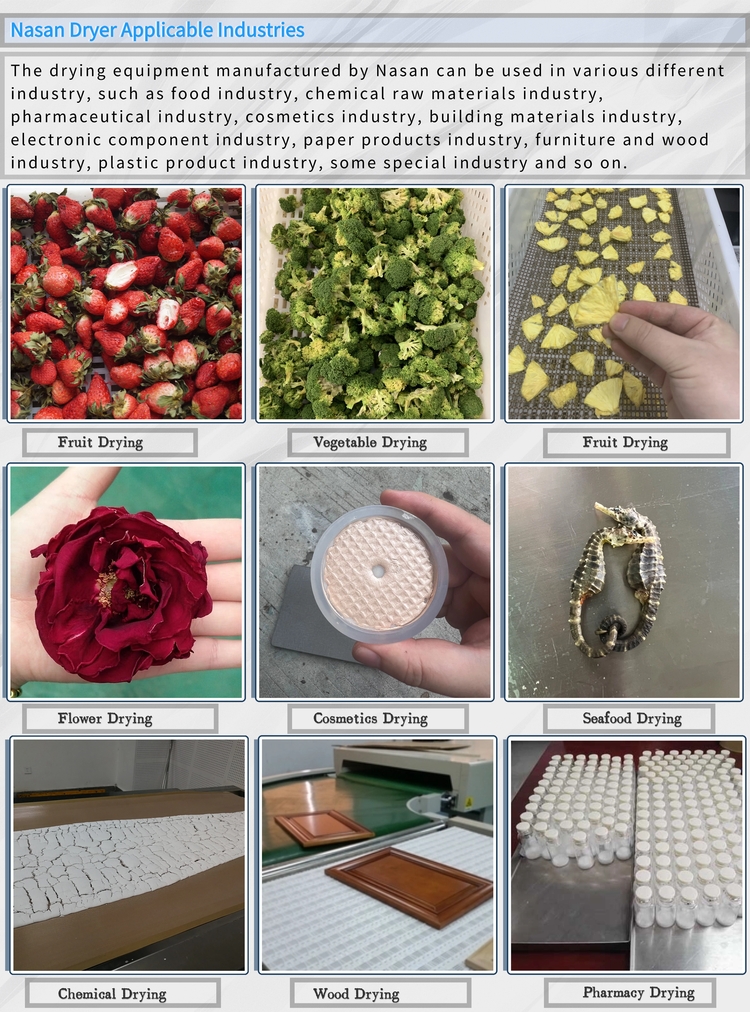

Freeze-drying equipment has significant application value in the pharmaceutical, food, and scientific research fields, producing high-quality dried products with a long shelf life and easy storage and transportation. It meets the stringent material property requirements of modern industry while adhering to healthy and environmentally friendly production practices, making it a representative example of high-end drying technology.