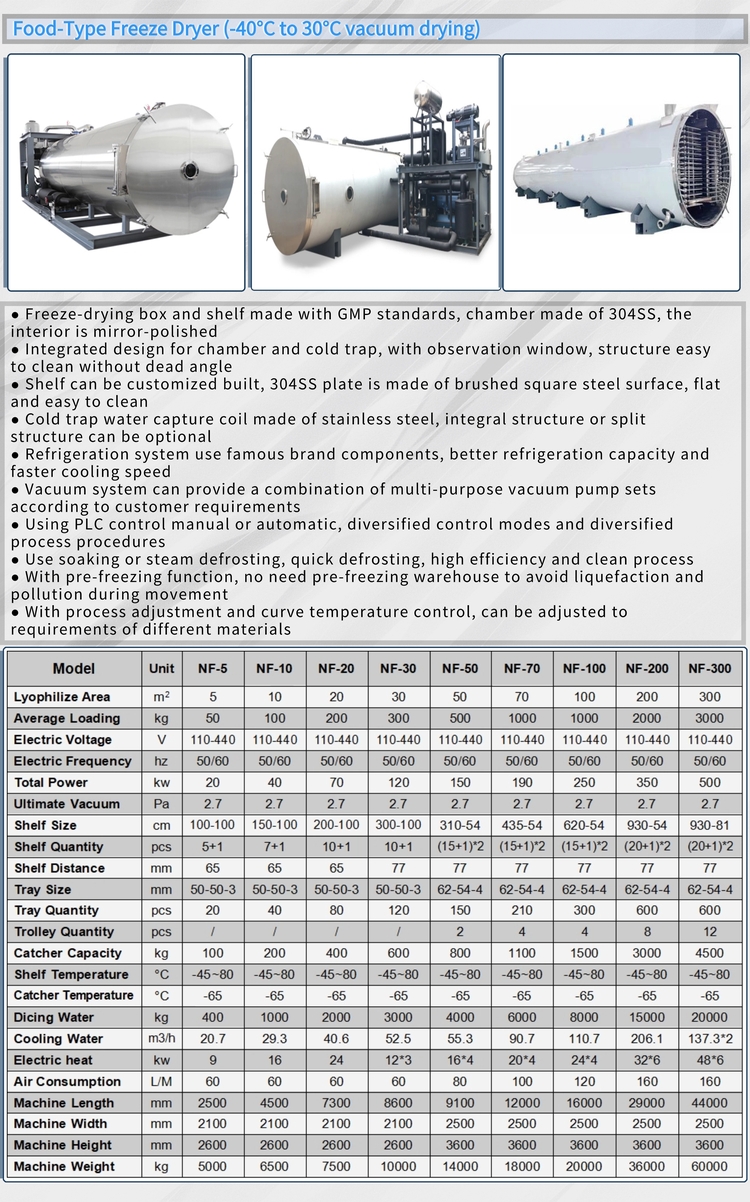

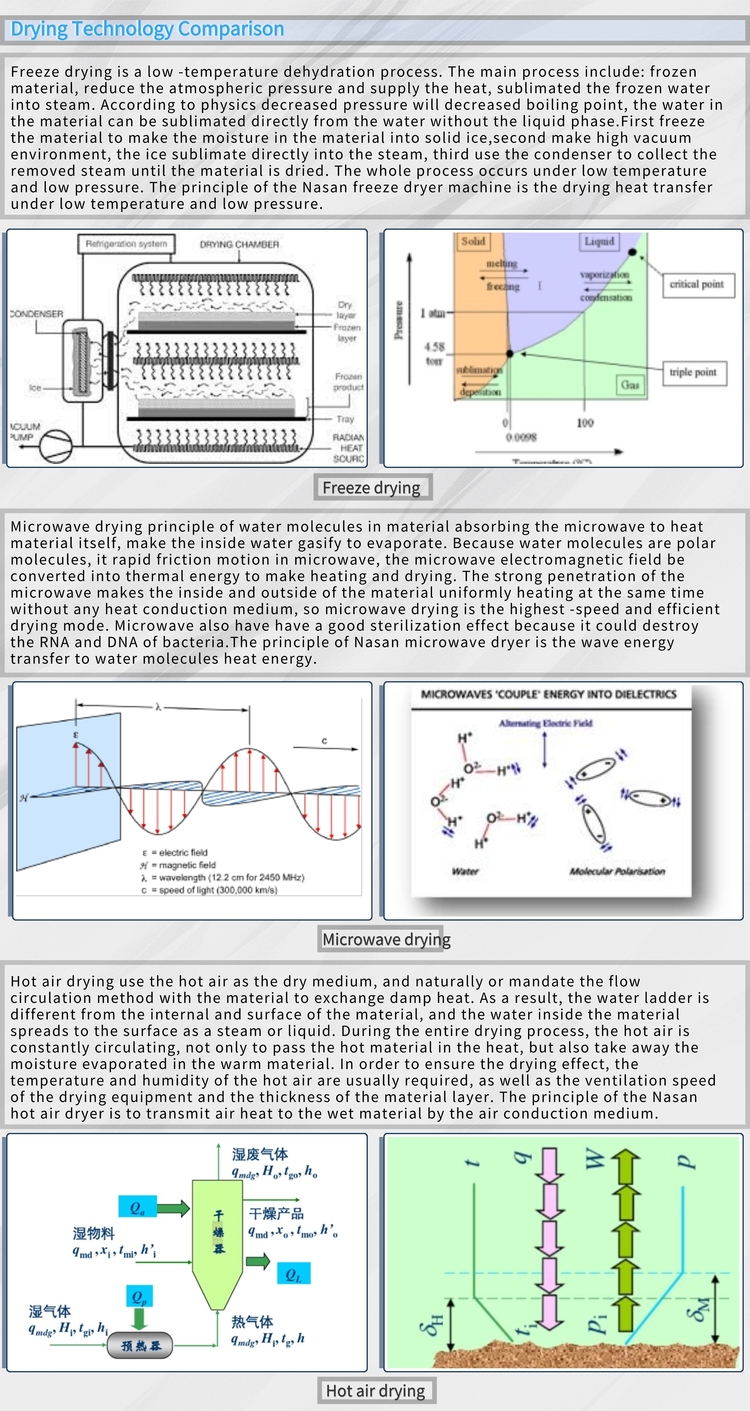

The industrial freeze dryer is a high-efficiency dehydration device designed specifically for large-scale production. It utilizes advanced freeze-drying technology to achieve industrialized material dehydration. It consists of a pre-freezing system, a vacuum system, a heating system, a cold trap system, and a central control system, meeting the requirements of continuous and automated production.

The equipment operates at temperatures ranging from -60°C to +80°C, with an ultimate vacuum of ≤8 Pa. It features a large-capacity -80°C cold trap (with a water capture capacity of 1,000 kg per batch). Constructed from industrial-grade 316L stainless steel, its modular design supports drying areas ranging from 5 to 200 square meters. The intelligent control system integrates a PLC and HMI interface, enabling multi-stage programmable temperature control, remote monitoring, and production data traceability.

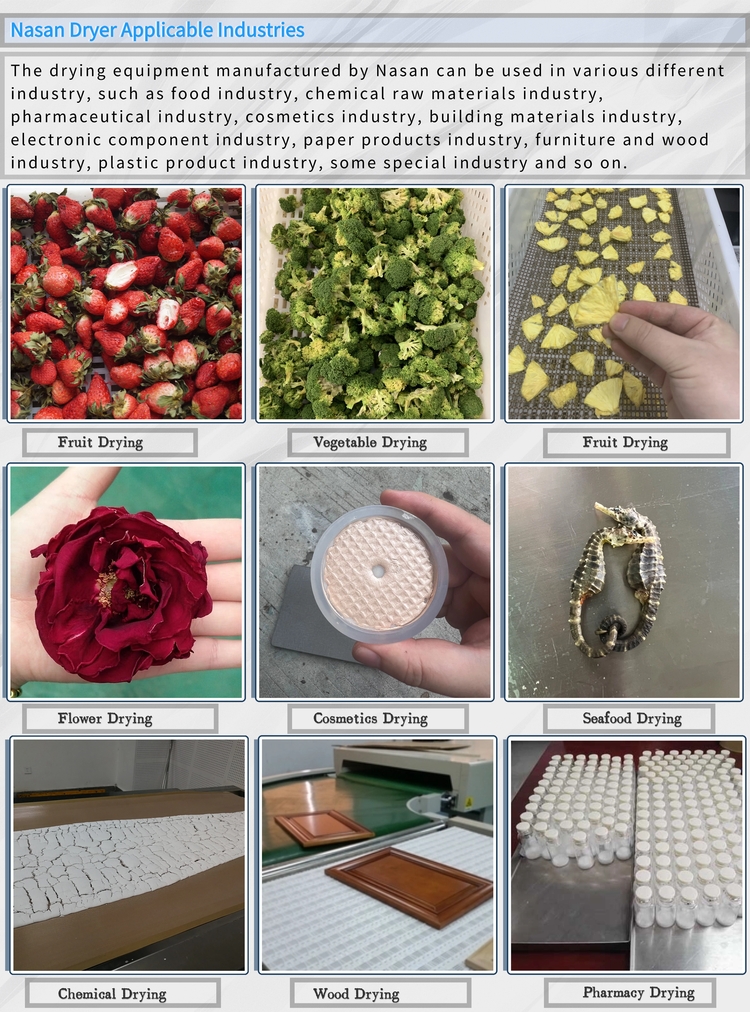

This equipment is particularly suitable for large-scale production in the pharmaceutical, food, and chemical industries, with single-batch processing capacity reaching hundreds to thousands of kilograms. Compared to traditional drying methods, it significantly improves product quality and reduces energy consumption by over 30%, making it a core value-added component in modern industrial production. The equipment complies with international standards such as GMP and FDA and can be customized to meet the specific needs of different industries.