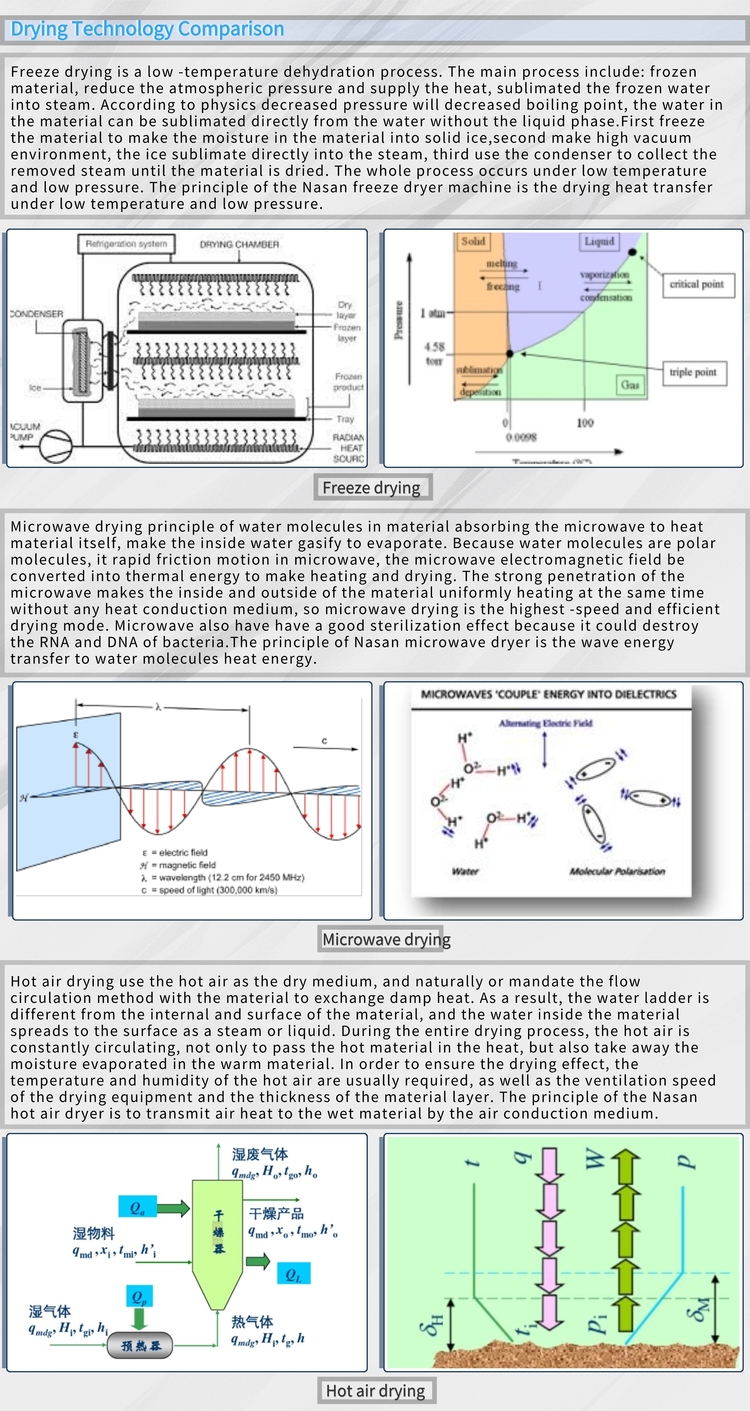

The freeze-microwave vacuum dryer is a highly efficient drying device that combines cryogenic freezing, microwave heating, and vacuum dehydration. This device first freezes the material to below -40°C and then applies microwave energy in a vacuum environment (10-100 Pa), causing the moisture in the material to sublime directly from solid ice to water vapor.

The device utilizes a unique microwave uniform distribution system to ensure uniform heating of the material, preventing local overheating. It also features an intelligent temperature control system that precisely controls the drying temperature within a range of -30°C to 60°C. Compared to traditional freeze-drying equipment, it can shorten drying time by 50%-70% and reduce energy consumption by over 30%, making it particularly suitable for rapidly dehydrating heat-sensitive materials.

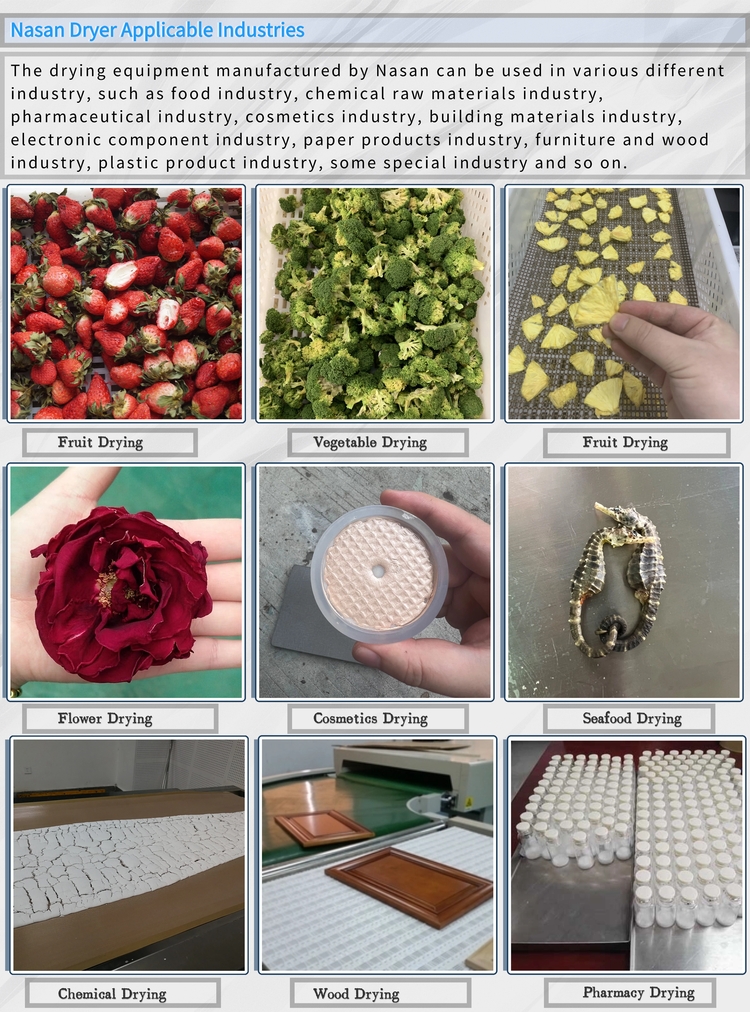

This device is widely used in the pharmaceutical, food, and chemical industries, and is particularly well-suited for processing high-value, temperature-sensitive materials. Its advantages include preserving active ingredients, shortening drying cycles, improving energy efficiency, and enhancing product quality. The device's modular design allows process parameters to be adjusted based on the characteristics of the material, meeting diverse needs from laboratory research and development to industrial production.